AI Vision for waste management led to 62% fewer unsafe events and 1.8× ROI within 9 months

Customer background

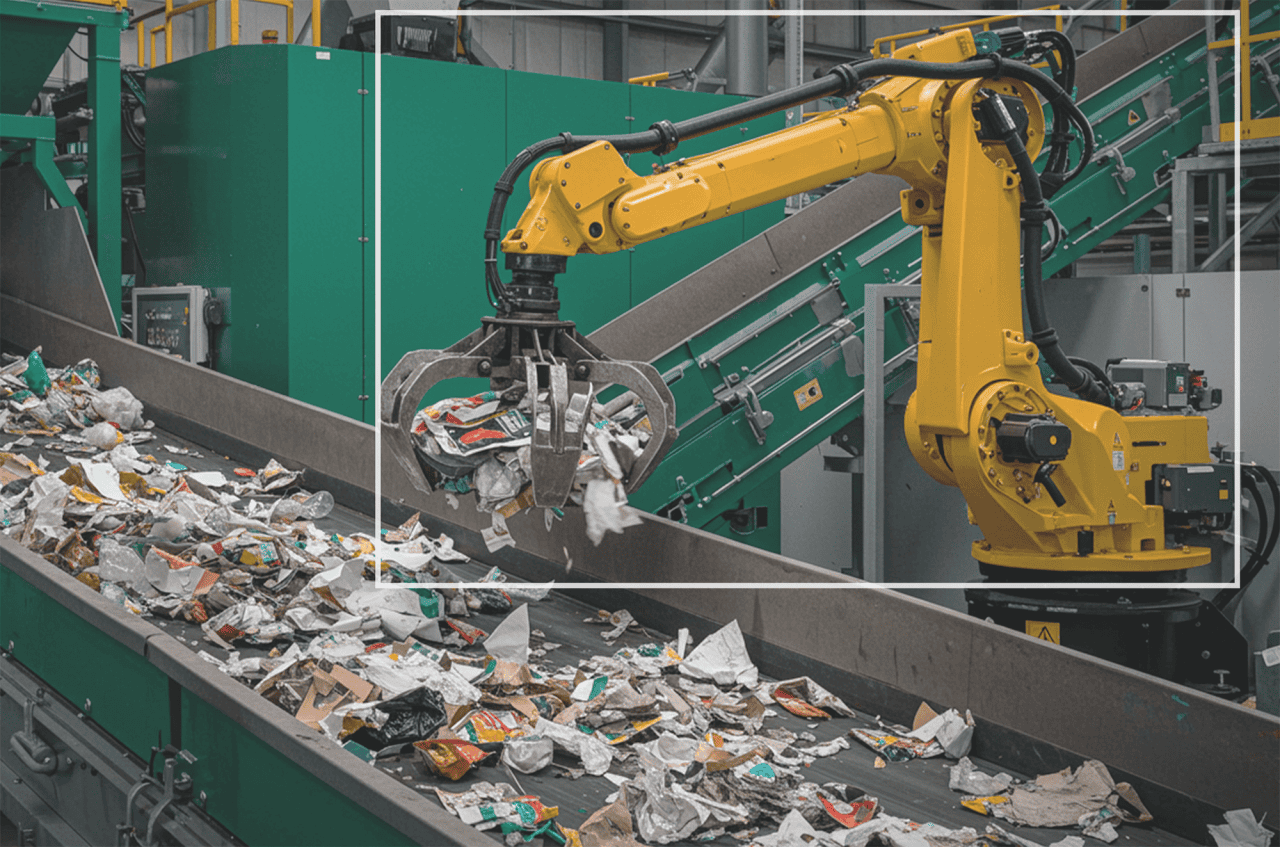

A leading waste management company operating across multiple material recovery facilities (MRFs) partnered with viso.ai to modernize safety and operational oversight through AI Vision.

The business need

Starting with a three-month pilot at one selected site, the company deployed three high-impact computer vision use cases: restricted area monitoring, near-miss and unsafe proximity detection, and machine utilization and downtime logging. Following the pilot, the rollout has expanded to a second phase across four additional facilities, with new use cases including contamination detection and process adherence monitoring planned for phase three.

Challenges

Impact

Limited real-time visibility into restricted or hazardous zones.

Frequent near-miss incidents in yards congested with vehicles and personnel.

Poor data on machine utilization and unplanned downtime.

Heavy dependence on manual logs and delayed reporting.

Resolution

The solution

The company sought to be an early adopter of computer vision to gain real-time insight and pro–active safety intervention, moving from re–active reporting to continuous monitoring.

Cameras monitored entry into high-risk zones near shredders, conveyors, and balers. When workers entered without authorization or PPE, real-time alerts were sent to supervisors.

AI Vision models analyzed pedestrian-vehicle interactions, identifying instances of unsafe distance. Additionally we tracked and monitored machine operation states, automatically tracking uptime, idle time, and stoppages – data previously collected manually.

Encouraged by the success of the pilot, the company has now expanded AI Vision deployment to four additional facilities. Using templated configurations and pre-trained models, rollout time per site was reduced to under eight weeks.

Aggregate results across all sites have so far mirrored the pilot – consistent safety gains and improved equipment performance – while maintaining a near-zero increase in human monitoring workload.

“We finally have eyes where we never could before. Piloting and scaling with viso.ai helped us detect problems before they become incidents, and gave us data we can act on. This paves the way for scaling further to drive even greater ROI.”

Operations and Safety Director, Waste Management Division

Business results

- Restricted zone intrusions reduced from eight per month to just three (62% improvement)

- Near-miss proximity events dropped by nearly two thirds to 18 per month, from 50 (64% reduction)

- Machine uptime increased by over one fifth, from 72% to 88% (up by 22%)

- Unplanned downtime saw a fall of over half across the pilot (down by 58%)

- Investigation workload alerts moved from 30 manually to 10 automatically (an improvement of 67%)

- ROI of 180% was achieved in just nine months, leading to wider scope in subsequent phases of deployment

- Encouraged by the success of the pilot, deployment has extended to four additional facilities. Using templated configurations and pre-trained models, rollout time per site was reduced to under eight weeks.