54% fewer near-miss incidents with worker-trusted AI Vision

Customer background

A metals and heavy materials manufacturing organization operating high-throughput production environments faced ongoing safety risks related to near-miss incidents in shared human-machine work zones. Engineering control is not possible with these types of risk, so there is no effective, manual way to assess, control and eliminate them.

The business need

While recordable injury rates were within industry benchmarks, internal safety audits, insurance reviews, and workforce feedback highlighted a critical gap: near-miss events were significantly under-reported. These unrecorded incidents limited the company’s ability to proactively identify hazards and prevent serious injuries.

At the same time, the organization operated in a unionized manufacturing environment, where workforce trust, transparency, and joint governance were essential to the success of any new safety technology. Leadership recognized that improving safety outcomes would require not only better data, but also explicit workforce and union endorsement.

The company set a clear mandate:

- Start with the highest-impact safety use case

- Demonstrate measurable results quickly

- Build trust before expanding further

Challenges

Impact

Near-miss incidents were rarely captured at the moment they occurred

Safety teams were forced to react after incidents instead of preventing them

Training and safety coaching lacked objective evidence

Risk exposure remained high in shared human-machine areas

This disconnect between reported safety performance and actual operational risk created concern among leadership, regulators, and workforce representatives

Resolution

The solution

The Viso Suite for manufacturing industry Health and Safety was deployed in two phases across high-risk areas of the manufacturing operation.

Phase 1: Near-Miss Detection

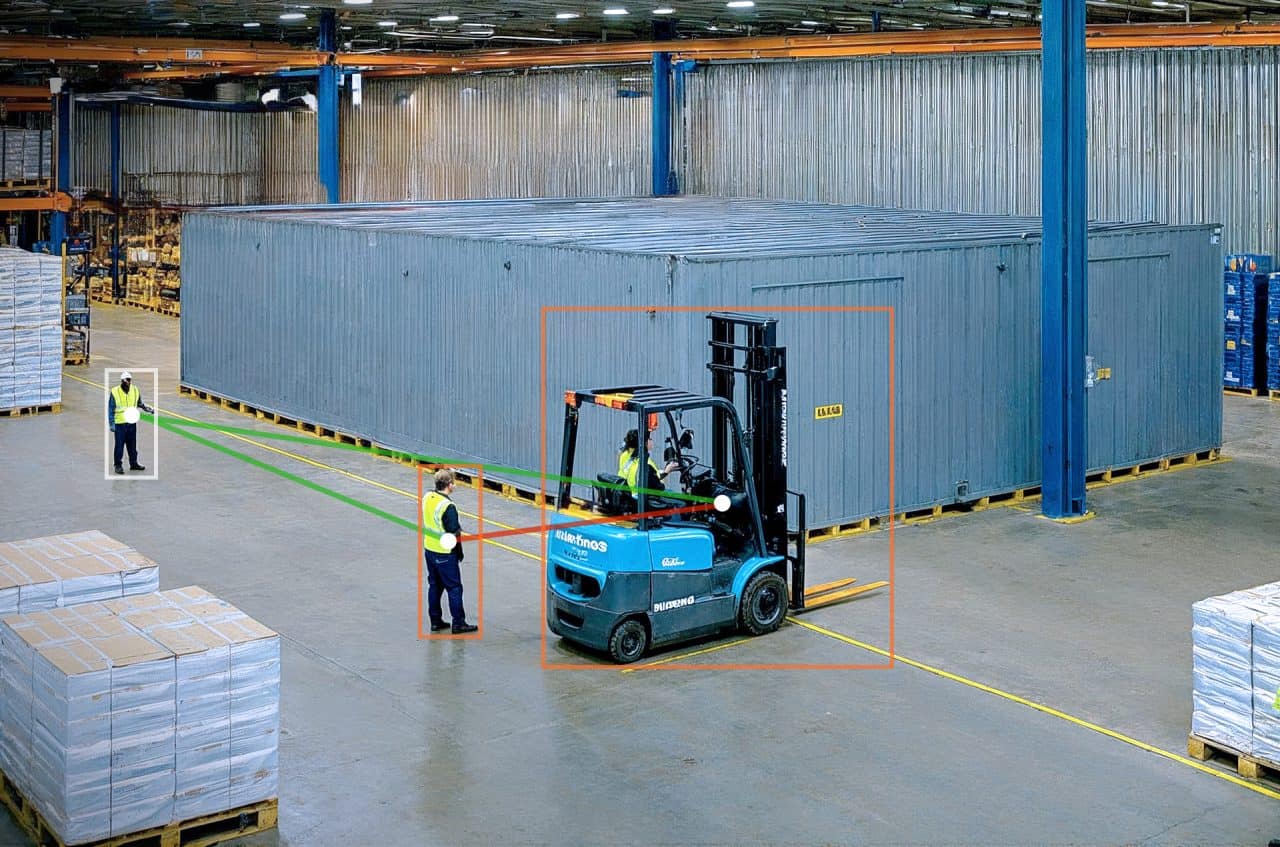

The initial deployment focused exclusively on identifying near-miss events in shared workspaces.

Key capabilities included:

- Real-time detection of unsafe human-machine proximity

- Hazard zone intrusion alerts

- Edge-based processing to protect worker privacy

- Aggregated reporting by area, shift, and risk type

- Alerts were designed to support immediate intervention and coaching, rather than individual monitoring.

Outcome: Within 90 days, near-miss incidents were reduced by 54%, validating the technology and reinforcing workforce confidence.

Phase 2: PPE Compliance

Following the success of Phase 1, and with strong workforce and union support, the company expanded the solution to include PPE compliance monitoring.

This phase focused on:

- Helmet, high-visibility vest, and glove detection

- Non-punitive alerts routed to supervisors and EHS teams

- Trend analysis to identify systemic compliance gaps

- Because trust had already been established, adoption was rapid and resistance minimal.

Outcome: PPE compliance improved by 47%, particularly during high-activity shifts and peak production periods.

Business results

Across the two-phase deployment, the company achieved clear and measurable outcomes:

- 54% reduction in near-miss incidents, lowering injury risk

- 47% improvement in PPE compliance, strengthening safety culture

- Earlier hazard identification and faster corrective action

- Reduced safety-related downtime and investigation costs

- Strong workforce and union endorsement of the AI Vision program

- A scalable foundation for future safety initiatives

Leadership also reported improved collaboration between operations, EHS teams, and workforce safety committees.

“What made this deployment successful was trust. Starting with near-miss detection allowed us to prove real safety value quickly, and the transparency of the system earned workforce and union support. Once that foundation was in place, expanding to PPE compliance was a natural next step.”

— Director of Health, Safety & Environment