Near-misses down 66% without a single new safety officer

Customer background

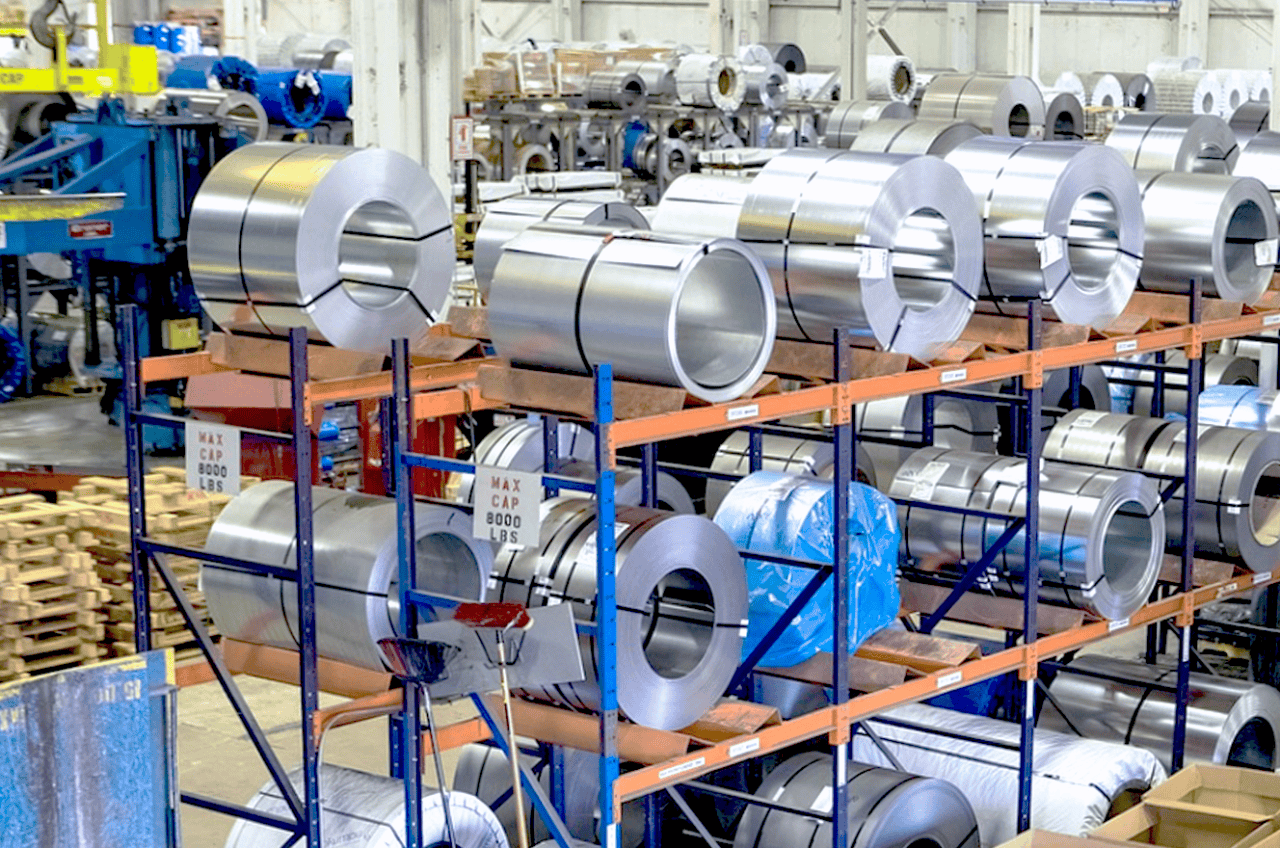

A diversified industrial manufacturer operating high-volume assembly, machining, and material-handling processes across multiple European plants, partnered with viso.ai to modernize safety and operational oversight through AI Vision. With thousands of workers, fast-moving equipment, and high compliance standards, the company sought a unified platform to manage safety across diverse manufacturing environments.

The business need

Starting with a three-month deployment at one selected facility, the manufacturer prioritized the two highest-impact computer vision use cases, namely PPE compliance and Speeding vehicle alerts.

After successful deployment, proving the technology and operational effectiveness, the rollout expanded to cover three additional manufacturing sites. Four additional new use-cases were also layered on, as per our standard approach to scaling, namely:

- Near-miss and unsafe-proximity detection

- Blocked-entrance detection

- Stocking-area and aisle obstructions, and

- Restricted-area monitoring

Challenges

Impact

Inconsistent PPE compliance across shifts and zones

Speeding forklifts and material-handling vehicles in congested aisles

Frequent vehicle–pedestrian near misses in mixed-use areas

Blocked emergency exits and unauthorized items stored near fire-safety equipment

Stocking-area overflows creating slip and trip hazards

Restricted-area intrusions, especially during maintenance

Heavy reliance on manual logging and delayed incident reporting

Resolution

The solution

The company aimed to become an early adopter of AI-powered safety automation, moving from reactive event reporting to continuous, pro-active monitoring across all shifts, teams, and zones.

Using existing camera infrastructure, the manufacturer benefited from multiple detections through the single platform.

Speeding-vehicle alerts

Vehicle-speed estimation detected forklifts and other frequently used vehicles exceeding safe operating limits, particularly in shared aisles and loading areas.

PPE compliance monitoring

AI Vision detected missing high-visibility vests, gloves, glasses, hard hats and zone-specific protective equipment. Alerts were sent when workers entered production cells without required PPE. Privacy-preserving, pixelated ‘fuzzy-face’ anonymization was applied automatically, enabling high compliance while maintaining worker trust.

Near-miss and unsafe-proximity detection

AI models monitored pedestrian–vehicle interactions, identifying breaches of safe distance thresholds and providing incident heatmaps to safety teams.

Blocked entrances and fire-exit alerts

Vision models monitored emergency exits, fire-extinguisher zones, and evacuation routes for unsafe obstructions or stored items.

Stocking-area overflow detection

AI identified clutter, misplaced pallets, and overfilled staging zones, helping maintain clear process flow and reduce trip hazards.

Restricted-area monitoring

Real-time alerts triggered when unauthorized personnel entered restricted areas like maintenance-only zones, robot workcells, and chemical storage areas.

Scaling six critical safety use cases on a single platform

Ramping up to deploy all six use cases on a single platform allowed the client to:

- View all safety events in a unified dashboard, creating a single source of truth across shifts, lines, and facilities

- Reduce operational overhead by eliminating multiple point solutions, manual checks, and fragmented reporting

- Reuse site templates, tried-and-tested processes and calibrated models to onboard new facilities rapidly and consistently

- Scale to multi-site operations with near-zero added complexity, using standardised pipelines and automated configuration

- Lower total cost of ownership (TCO) by consolidating licensing, maintenance, and analytics into one platform, rather than six separate systems

- Improve decision-making with cross-site analytics, enabling benchmarking, trend detection, and predictive risk insights at a portfolio level

- Accelerate time-to-impact, with new use cases deployable in hours, not months, with standardised processes and reusable infrastructure

Future phases

Encouraged by strong early impact, AI Vision usage has expanded to three additional manufacturing facilities. Templated configurations and pre-trained detection models reduced rollout time to under six weeks per site, with each location achieving stable accuracy within days.

Planned next-phase use cases include:

- Process-adherence monitoring for critical workstations

- Material-handling validation (correct pallet orientation, load security)

“Deploying AI Vision has given us real-time visibility into almost every major safety risk across our plants. From PPE, forklift behavior, blocked exits, restricted areas, and more, we can monitor, detect and intervene, all through a single, unified platform. Preventing incidents before they occur, rather than responding to them is a game-changer. The shift has been extraordinary: safer operations, faster interventions, higher compliance, and the highest level of confidence that privacy is protected.”

— Director of Operations and HSE, Manufacturing Division

Business results

- PPE non-compliance reduced by 41%, with consistent improvement across all shifts

- Speeding-vehicle incidents reduced by 52% within 90 days

- Near-miss proximity events dropped by 66%, decreasing from an average of 45 to 15 per month

- Blocked exits and aisle obstructions decreased by 71%, improving audit readiness

- Restricted-area intrusions cut by half, reducing high-severity risk exposure

- Investigation workload reduced by 63% as automated event logs replaced manual reporting

- 2.1× ROI achieved within 12 months, driven by fewer incidents, reduced downtime, and productivity gains

- Scalable deployment to three additional facilities, using templated configurations and pre-trained models, completed in under six weeks per site