ROI Calculator

Estimate injury exposure from near-miss, unsafe acts and unsafe conditions data. Reveal the ROI of safety improvements.

Health and Safety ROI Calculator

Inputs

(incident exposure : minor : major)

Results

"*" indicates required fields

Expected Injuries

Financial Risk

Heinrich's Pyramid

Addressing unsafe actions, unsafe conditions, near misses early reduces downstream costs.

Narrative

-

How it works

The calculator models Heinrich’s Safety Pyramid for your organisation, translating near-miss, unsafe acts, and unsafe conditions data into predicted minor and major injuries, then into cost exposure and ROI.

In a single view you can compare the “do-nothing” baseline to targeted reduction scenarios. Use the generated narrative to brief leadership, align departments, and set measurable targets during safety reviews or improvement sprints.

Entirely browser-based, it runs seamlessly on desktop or mobile, ideal for workshops, boardrooms, or the factory floor. You get your results in seconds.

Step One: enter straightforward data

1. Near misses, unsafe acts, and unsafe conditions

2. Average minor-injury cost, and

3. Major-injury cost

Step Two: see the results for yourself

Instantly see projected incidents and exposure based on Heinrich’s 300:29:1 ratio. Results update in real time, so you can explore scenarios in seconds.

Don’t have the data to hand, or want to explore based on industry standards instead?

No problem. The calculator comes pre-loaded with an estimate you can build from.

Step Three: access your free discovery call and demo.

Ask your questions, hear from our experts, and begin to unpack what AI Vision can do for your specific needs.

Five key benefits

- Quantified baseline risk: see likely incidents and total cost exposure.

- Instant narrative output: ready-made summary for leadership discussions.

- Scenario toggles: model expected versus rounded outcomes.

- Visual pyramid insight: illustrate why tackling near-misses pays off.

- Clear next steps: connect financial exposure to AI Vision safety controls.

Implementation micro-timeline

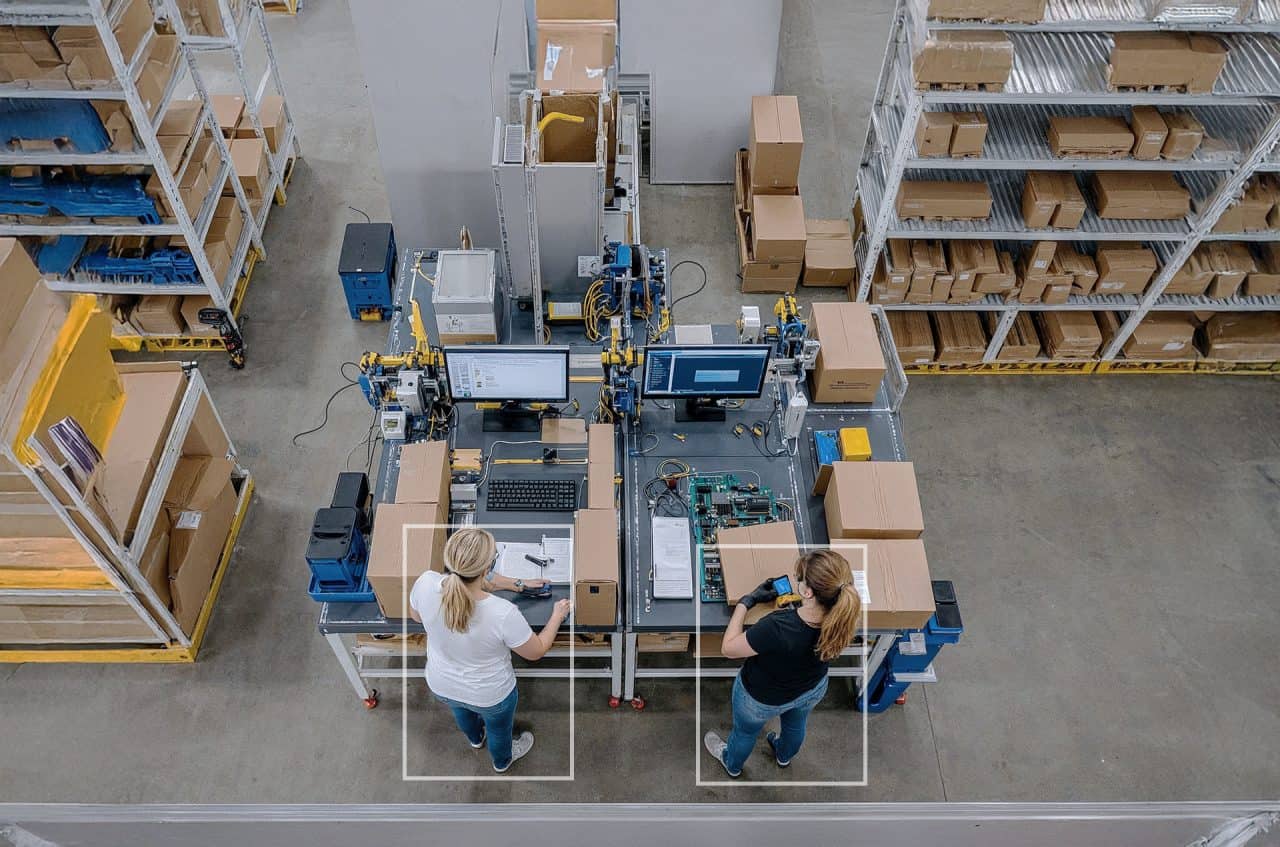

- Deploy: Install cameras and vision models to collect data fast

- Detect: Identify defects, bottlenecks, anomalies, and safety issues

- Act: Respond and optimize, triggering alerts and preventing failures

- Improve: Track ROl: reduce defects, increase throughput and lower downtime

- Scale: Add more cameras, lines and sites to strengthen the system

Why AI Vision matters

AI Vision acts as a digital safety layer that detects and flags these issues early, reducing injuries, downtime, and insurance costs. It continuously strengthens your path to zero harm in manufacturing, construction, logistics, waste management, and more.