In an industry where “zero harm” is more than a slogan, turning construction safety ambitions into outcomes is a constant challenge. At our recent webinar, HDI (a VINCI Construction company) and viso.ai pulled back the curtain on a live, large-scale deployment of AI Vision across a number of construction sites. We explored AI Vision on the frontline: how HDI is bringing real-world safety innovation to construction sites.

This article summarises key lessons, outcomes, and implications for HSE and lean/efficiency leaders in construction.

Why this matters: construction safety and efficiency at scale

Construction remains among the highest risk industries for serious injury and fatality. AI in construction safety (especially computer vision) is emerging as one of the most promising levers to shift from reactive compliance to proactive prevention.

But success is not just about tech: it’s about making AI accessible, reliable, and trusted in unpredictable, real-world construction environments. Leaders in HSE, lean, continuous improvement, and efficiency, will recognise the familiar tensions: how to reduce waste, how to measurably change behaviour, how to roll out something new across dozens of sites, and how to make sure it doesn’t become yet another siloed tech trial.

In this deployment, HDI essentially treated AI Vision primarily as a safety tool: compact, value-adding, part of workflows, scalable, not a heavyweight R&D experiment.

From curiosity to commitment: HDI’s starting point

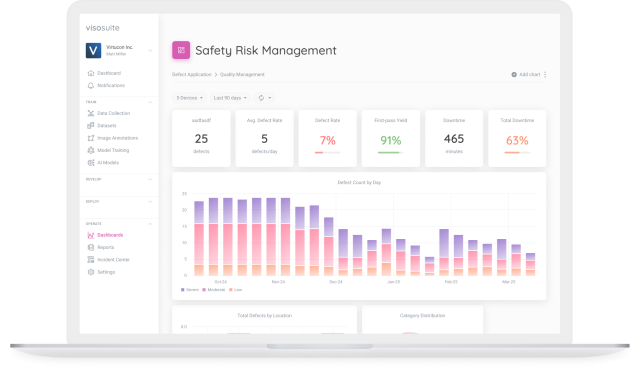

When HDI first engaged with AI Vision, their safety systems were heavily manual: observations, toolbox talks, audits, incident reports, and reactive follow-up. Fast forward: today, they run deployments on multiple live sites with five active AI use cases, using only four cameras and one edge device per site. HDI’s key motivation was simple but deep: reduce blind spots, make safety visible, and prevent incidents – not merely record them after the fact.

As their HSE sponsor put it:

“With heavy machinery, moving loads, and shifting site layouts, manual observation just doesn’t cover enough. AI Vision gives us real-time visibility, site-specific adaptation, and the ability to act before things go wrong.”

Five use cases in live deployment

Through four cameras per site (feeding into a single on-site AI device, no cloud dependency), HDI currently runs five core vision-based safety applications. These are:

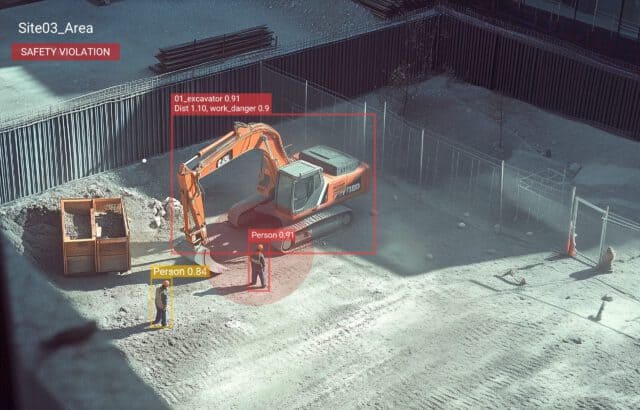

1. Person under load detection

Alerts when someone walks underneath a lifted load (e.g., excavator bucket).

2. Man-machine proximity monitoring

Especially in machinery blind spots – critical for preventing collisions or pinch points.

3. Housekeeping detection

Hazards like stray construction bags seem inconsequential but repeatedly cause blocked routes and inefficiencies.

4. PPE compliance at entry/checkpoints

Gear detection (hard hats, vests, etc.) as workers enter zones.

5. Restricted/exclusion zone detection

Ensuring no person is in a crane swing radius, or within the drill’s “most restricted limits” (MRL) when it’s active.

These systems feed alerts into HDI’s central incident centre, where HSE leads review them. The system is not passive: it’s actively shaping supervision, escalation, and safety behaviour.

Each detection event creates a verified data point that can be analysed over time to identify recurring risks, non-compliance patterns, or hotspot areas across sites.

Supervisors use this insight to adjust workflows, retrain crews, and reconfigure layouts to prevent repeat incidents. By translating daily visual data into measurable trends, HDI is turning frontline observations into continuous business improvement—reducing downtime, enhancing compliance, and embedding a proactive safety culture across operations.

One standout technical aspect is that by all processing operating at the edge, we removed any cloud dependency. This means there’s no latency, no reliance on unstable networks, and no burdensome data transfer.

Outcomes, ROI, and behavior change

The actionable insights generated showed that this was an immediate and long-term value generator. HDI already had a zero-accident rate and robust safety policies in place. However, by adopting AI Vision, they were able to streamline and standardise safety, automating some workflows, freeing their teams up to more added-value activity.

The results of their already progressive and best-practice HSE policies and procedures, being amplified by deploying AI Vision, saw multiple benefits

- Near-misses are consistently caught before escalation

- Supervisor response times have improved: alerts go straight to stakeholders, whose already rapid response times can now be even quicker

- Comparative performance data between sites is now possible – they continuously benchmark safety effectiveness

- But perhaps most importantly, behaviour has shifted: HDI’s people now expect insights from the system.

From a business perspective, HDI is moving to multi-year renewal, expanding its deployment, and is soon to be covering more than ten sites, signalling confidence not only in the technology, but in the collaborative delivery model.

What made it work (and what to watch out for)

From the webinar discussion, a few themes emerged as critical success factors and caution points for those looking to deploy AI Vision.

1. True partnership and co-development

HDI’s HSE leads didn’t just benefit from receiving a solution: they actively shaped it. Weekly alignment, openness to iteration, executive sponsorship from site to boardroom: all reinforced the importance of the pilot collectively, the focus on tangible benefits, as well as individual accountability.

2. Pragmatic technical design

Together, the team solved for constraints: limited bandwidth, edge device capacity, power or network instability, and site environmental noise. The compact four-camera and one-device architecture was deliberately lean.

3. Iterative rollout, not big bang

HDI did not attempt to cover multiple sites in one go. They scaled stepwise, learning as they went.

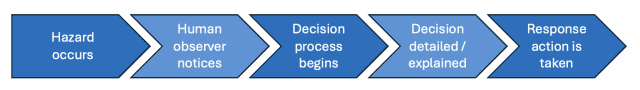

4. Escalation and adoption processes

Deploying the tech is one thing; using it is another. At some sites, the system is fully embedded into workflows; at others, adoption is still climbing. HDI maintains escalation plans, training, and site-level governance so that alerts actually drive meaningful change.

5. Environment unpredictability

Construction sites are messy and dynamic: scaffolding, dust, fluctuating light, shifting zones. Even weather, power outages, and building movement affect camera stability. The solution must be robust, resilient, and adaptable.

What next? HDI’s roadmap and broader scale

HDI’s immediate next step is to extend to additional sites, towards a multi-site footprint. But the ambition is bigger: they are now sharing results across their parent group, VINCI Construction, planning demos, innovation days, and potentially group-level adoption. As such, they are pioneering innovators within the group, paving the way for the collective organization to benefit even more.

HDI’s focus is on expanding its use of AI Vision beyond initial safety cases to cover a wider range of operational risks, such as fall detection, housekeeping change monitoring, and scaffolding safety. The goal is to make intelligent vision a standard part of site safety infrastructure, fully integrated into daily operations rather than treated as an add-on.

By doing so, HDI aims to create a continuously learning safety system: one that not only detects risks in real time but also helps prevent them through data-driven insights and safer work design.HDI’s approach shows how a partner-led model, lean deployment, and incremental scaling can turn AI Vision from curiosity into a core HSE capability.

Lessons and practical advice for HSE, lean, and efficiency leaders

If you’re considering AI Vision for your construction environment, here’s what to keep in mind based on HDI’s experience:

Start with a pilot, not a full roll-out

Begin with 1 or 2 use cases in up to 3 sites, test robustness, workflows, and adoption.

Privacy-by-design approach

Align with industry standard compliance in mind (SOC2, ISO27001, and GDPR)

Co-design with frontline HSE/site teams

Guarantee buy-in and usability.

Design for Edge / local resilience

Construction sites aren’t stable networks – avoid solutions that depend on reliable connectivity.

Embed adoption governance

Alerts are worthless if nobody trusts or acts on them.

Measure behaviour, not just alerts

Use the data to drive safety culture, not just compliance.

Anticipate scaling constraints

Watch device capacity, camera counts, environmental noise, power, and network volatility.

Above all: consider AI Vision not as “another tech project” but as a lean safety tool – compact, value-driven, scalable, and integrated.

Broader context: AI, lean, and safety trends in construction

To reinforce why this is so relevant, it’s worth aligning it with sector trends that HSE and lean roles are already tracking:

Shift from reactive to proactive safety

AI enables continuous hazard detection, not just periodic inspections.

Efficiency, waste reduction, and Lean synergy

Lean construction emphasises elimination of waste, optimised workflows, and value delivery. Integrating AI Vision helps reduce waste in safety – e.g., fewer observations required, fewer incidents to follow up, faster root-cause correction.

Data-driven decision-making and benchmarking

One of the powerful by-products of AI is structured, comparable data across sites – enabling continuous improvement, safety KPIs, and cross-site benchmarking.

Regulatory and governance readiness

In the UK, HSE already signals that AI is within the scope of health and safety law. Risk assessments, transparency, explainability, and human oversight remain foundational

Adoption barriers remain real

Studies highlight challenges in AI deployment: data quality, environmental variability, trust, and change management.

Thus, HDI’s successful outcomes are not isolated – they align with where the industry is heading and provide a blueprint for how to do it safely and pragmatically.

Conclusion: real-world AI Vision, real impact

The value of the webinar we ran with HDI is to show that AI Vision is not futuristic – it’s happening today, at scale, and delivering measurable impact.

For HSE, lean and efficiency leaders in construction:

- You don’t need 100 cameras or perfect conditions – start small, instrument high-risk zones, and build trust

- Partner from the start – this is not a tech handoff, it’s a shared journey

- Focus on outcomes: behaviour change, supervisor response, reduced near-misses – not just alert counts

- Be ready for constraints (device capacity, environment, adoption friction) – but don’t let perfect block progress

HDI’s journey demonstrates that AI Vision can truly shift safety from compliance to prevention, amplifying what your frontline teams can see and act on. If you’re exploring AI Vision for your own sites, learn from HDI’s experience – and let us help you turn vision into frontline action.

You can view the on-demand webinar in full here.