Introduction: intelligent safety and the eyes that never blink

In the world of health and safety, the stakes have never been higher: intelligent safety policies, practices and procedures are no longer simply a ‘nice to have’ option.

The complexity of modern worksites – across construction, manufacturing, logistics, and warehousing – has turned safety management into a balancing act of prevention, compliance, and crisis mitigation.

With global regulatory scrutiny tightening and operational hazards growing, health and safety managers are under constant pressure to ensure that every inspection, standard operating procedure (SOP), and risk mitigation plan actually works.

Despite massive investments in intelligent safety training, manual audits, and compliance software, one truth remains: incidents still happen. From forklift collisions to PPE violations, near misses, and slip-trip-fall events, reactive safety models are no longer enough.

But what if your workplace could see the hazards before they become incidents?

Computer vision (also known as AI Vision) has now evolved beyond simple detection to become a truly intelligent safety partner.

A new era in intelligent safety: vision-based monitoring tools

AI Vision – a powerful branch of artificial intelligence that uses cameras to “see”, analyze, and understand environments in real time – has become ‘the eyes that never blink’. They can work 24/7 to detect, alert, and report on everything from PPE compliance to zone breaches, behavioral anomalies, and lockout-tagout violations.

No more reliance solely on clipboard checks or after-the-fact incident reporting. Vision-based Health and Safety (HSE) tools bring real-time hazard detection, automated safety inspections, and predictive risk modeling to life. That’s intelligent safety in action, around the clock.

Crucially this gives safety professionals not just a snapshot, but a live feed of everything that matters.

Organizations using AI Vision platforms report:

- Up to 90% reductions in manual audits

- 60% faster incident response times

- Complete visibility over SOP deviations and rule breaches, and

- Real-time compliance benchmarking against OSHA and local safety regulations

The next frontier: revolutionary advances in AI Vision safety

As we stand at the threshold of a new era in workplace safety, AI Vision technology is poised for transformative leaps that will fundamentally reshape how we think about hazard detection, risk prevention, and safety management.

Here are ten groundbreaking advances that we believe may well define the next five years of visual intelligence and AI Vision for health and safety: delivering intelligent safety as never before.

1. Contextual scene understanding through true visual intelligence

Unlike current systems that detect specific objects or behaviors, true visual intelligence-powered safety platforms will understand entire workplace contexts with human-like comprehension.

These systems will recognize not just that a worker is near equipment, but fully understand the:

- worker’s intent

- equipment operational state

- environmental conditions, and

- complex interplay of factors that create risk scenarios

This contextual awareness will enable safety systems to differentiate between routine maintenance activities and dangerous improvisation; between authorized access and security breaches; and between normal operational variations and genuine safety concerns.

The result? Dramatically reduced false alarms and more nuanced, intelligent safety interventions.

2. Predictive behavioral risk assessment

Advanced behavior analysis AI will move beyond detecting current unsafe actions to predicting future risk behaviors based on subtle visual cues.

These systems will analyze:

- micro-expressions

- body language

- movement patterns, and

- interaction styles

In doing so it will be possible to identify workers who may be experiencing fatigue, stress, distraction, or other states that increase accident probability.

By combining visual behavioral analysis with environmental factors, equipment status, and historical incident data, these systems will generate individual risk scores for workers throughout their shifts.

Safety managers will receive early warnings about workers who may need breaks, additional supervision, or modified duties to prevent incidents before they occur.

3. Multi-modal sensor fusion for comprehensive risk assessment

The integration of computer vision with other sensing technologies will create unprecedented situational awareness.

Intelligent safety vision systems will seamlessly incorporate data from:

- environmental sensors

- wearable devices

- equipment telemetry, and

- acoustic monitoring

This step-change will create comprehensive risk pictures that no single technology could achieve alone.

For example, a vision system detecting a worker entering a confined space will simultaneously:

- assess air quality readings

- check the worker’s physiological indicators from wearables

- verify proper lockout-tagout procedures through equipment sensors, and

- monitor communication signals to ensure continuous contact

This multi-modal approach will provide holistic safety oversight that adapts to complex, real-world scenarios.

4. Autonomous safety intervention systems

The next generation of computer vision safety platforms will move beyond detection and alerting to autonomous intervention.

These systems will automatically activate intelligent safety controls without human intervention when critical risks are detected, including:

- stopping equipment

- deploying barriers

- activating ventilation systems, or

- triggering emergency protocols

Advanced AI will assess the severity and immediacy of risks to determine appropriate intervention levels, from gentle audio reminders to immediate equipment shutdowns.

These systems will learn from each intervention, continuously refining their decision-making to balance safety protection with operational efficiency.

5. Real-time safety training and guidance

AI Vision will transform safety training from periodic classroom sessions to continuous, contextual learning experiences.

When systems detect unsafe behaviors or near-miss situations, they will immediately provide personalized training interventions through:

- augmented reality displays

- mobile devices, or

- workstation monitors

Workers will receive just-in-time safety guidance specific to their current situation, their role, and their historical performance.

The system will track learning progress and adapt training methods to individual learning styles, ensuring that intelligent safety knowledge is reinforced precisely when and where it’s most relevant.

6. Advanced anomaly detection for unprecedented hazards

Next-generation anomaly detection AI will identify safety risks that have never been programmed or previously encountered.

These systems will establish baseline patterns for normal operations and immediately flag any deviations that could indicate:

- emerging hazards

- equipment failures, or

- process breakdowns

This capability will be particularly valuable for identifying novel risks arising from new technologies, changing work processes, or unprecedented combinations of factors.

The system will learn continuously from each anomaly, building an ever-expanding knowledge base of potential safety concerns.

7. Predictive equipment failure and maintenance safety

Computer vision systems will evolve to predict equipment failures before they create safety hazards, by analyzing visual indicators such as:

- vibration patterns

- wear characteristics

- fluid leaks, and

- operational irregularities

These systems will identify maintenance needs before they result in dangerous situations.

The integration of visual analysis with equipment operational data will enable precise predictions of when maintenance interventions are needed to prevent safety-critical failures.

This pro-active approach will eliminate many equipment-related incidents while optimizing maintenance schedules for both intelligent safety and improved efficiency.

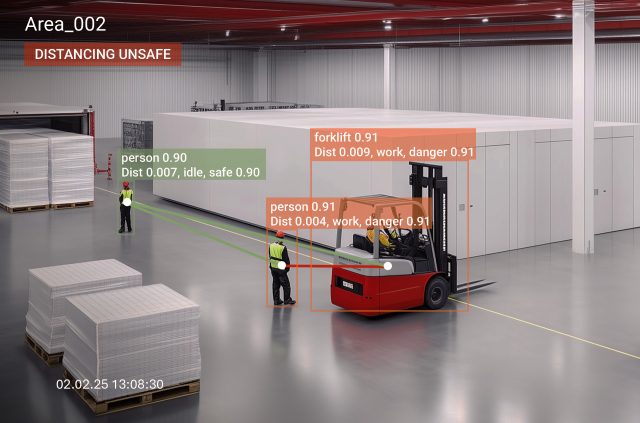

8. Intelligent crowd and traffic flow management

Advanced vision systems will manage complex movement patterns in busy workplaces, optimizing traffic flows to minimize collision risks and congestion-related hazards.

These systems will analyze pedestrian and vehicle movements in real-time. In doing so they would predict potential conflict points, and automatically adjust traffic signals, barriers, or routing recommendations.

In warehouses, construction sites, and manufacturing facilities, intelligent flow management will:

- reduce forklift-pedestrian interactions

- eliminate bottlenecks that create rushing behaviors, and

- ensure that emergency evacuation routes remain clear and accessible

9. Personalized safety ecosystem integration

Future AI Vision will create personalized, intelligent safety ecosystems for individual workers, integrating their:

- safety history

- training records

- physical capabilities, and

- current assignments

This will be enabled with real-time environmental monitoring.

Each worker will have a dynamic safety profile that influences how the system monitors their activities and what interventions it provides. This personalization will extend to adapting safety protocols for workers with disabilities, temporary limitations, or specialized roles.

The system will ensure that safety measures are appropriately tailored while maintaining consistent protection standards across the organization.

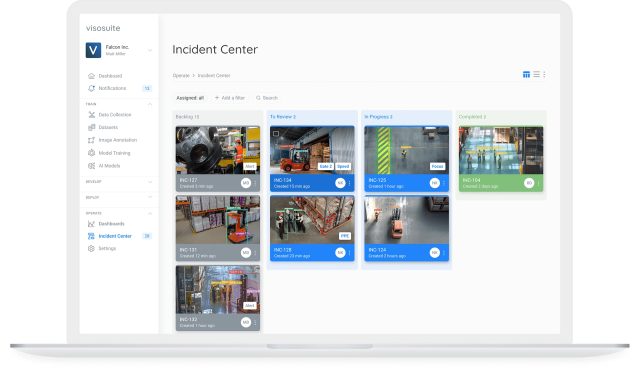

10. Regulatory compliance automation and reporting

Advanced vision systems will automatically generate comprehensive regulatory compliance documentation, creating detailed records of:

- safety activities

- incident responses, and

- corrective actions

These systems will understand regulatory requirements across different jurisdictions and automatically format reports to meet specific agency standards.

The integration of blockchain technology may create tamper-proof safety records that provide indisputable evidence of compliance activities.

This automated documentation will eliminate much of the administrative burden associated with safety compliance while ensuring that all regulatory requirements are consistently met.

The rise of adaptive safety: learning and evolution

Feedback from early adopters is shaping the next generation of AI-driven health and safety. As one safety manager described it:

“It’s like having a digital supervisor: one that never sleeps, never misses a violation, and never lets data go to waste.”

The most exciting aspect of these advances is their adaptive nature.

Unlike static safety systems, these intelligent safety platforms will continuously learn from workplace interactions, incident patterns, and environmental changes.

They will evolve their understanding of risk factors, refine their prediction algorithms, and adapt their intervention strategies based on real-world feedback.

This continuous learning capability means that safety systems will become more effective over time, developing nuanced understanding of:

- specific workplace cultures

- operational patterns, and

- risk profiles

The result will be safety oversight that feels less like surveillance and more like intelligent partnership.

Implementation horizons: when these advances will arrive

These transformative capabilities won’t arrive simultaneously.

Contextual scene understanding and advanced behavioral analysis are already emerging in pilot programs, with broader deployment expected within 18-24 months.

Multi-modal sensor fusion and autonomous intervention systems are projected for 2-3 year deployment, while the most advanced visual intelligence capabilities may require 3-5 years to reach commercial maturity.

However, the modular nature of modern AI platforms means that organizations can begin benefiting from these advances incrementally, upgrading their capabilities as new features become available.

Early adopters who establish vision AI foundations today will be best positioned to integrate these advanced capabilities as they mature.

Conclusion: the future of intelligent safety

The next five years will witness the transformation of computer vision from a useful safety tool to an indispensable intelligent partner in workplace protection.

These advances represent more than technological evolution. They signify a fundamental shift toward truly intelligent, adaptive, and proactive safety management.

For health and safety managers, the message is clear: the future of workplace safety will be defined by organizations that embrace these intelligent technologies today.

The eyes that never blink are evolving into minds that never stop learning, creating safer workplaces through unprecedented insight, prediction, and intervention capabilities.

The question isn’t whether these advances will reshape workplace safety: it’s whether your organization will lead this transformation or follow in its wake.

The future of safety is intelligent, adaptive, and already beginning to unfold.