Across industries, workplace safety remains one of the biggest operational challenges. Despite protocols and processes, incidents continue to happen, often because those systems aren’t actively enforced.

So what happens when you give your safety systems the power to see, understand, and act? That’s exactly what we explored in our latest webinar, “Seeing Safety: How AI Vision is Transforming Workplace Health & Safety”.

Featuring insights from co-CEO and co-founder Nico Klingler, and our expert Technical Account Manager, Abi Anderson, the session covered the role of AI Vision in seeing safety by:

- reducing risk on a path to zero harm

- improving safety processes and procedures, and

- enabling smarter site operations across multiple industries

If you would like to watch the on-demand video of the webinar – hosted by Chrissie Jamieson, our Vice President of Marketing – you can find it here.

Safety is not about more rules: it’s about enforcing them

Every year, nearly 3 million deaths occur globally due to workplace incidents, and many of those are avoidable. The issue isn’t a lack of safety protocols. Rather it’s that those protocols often go unenforced.

Health and Safety teams are stretched thin, and traditional approaches like surveillance footage and manual inspections can’t keep pace with the scale of operations. Without consistent visibility, adherence slips, and risks escalate.

Beyond the human cost, workplace injuries also come with a staggering economic burden, estimated at $3 trillion annually. This is due to legal and compliance fees, compensation claims, and productivity losses, among other costs.`

The need for scalable, always-on safety solutions has never been clearer.

Enter AI Vision: a smarter set of eyes that never blink

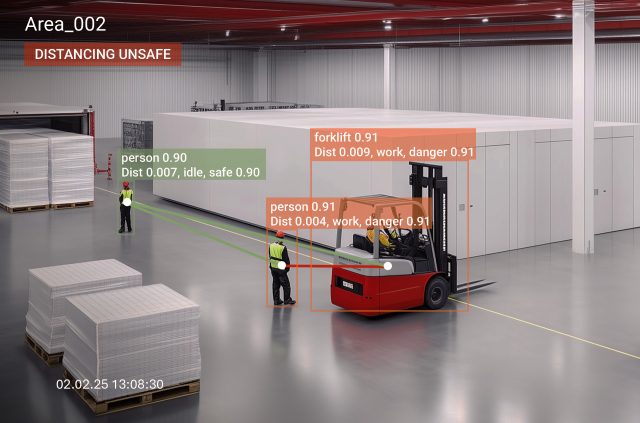

AI Vision offers a smarter, more pro-active way to manage risk. These systems analyze video feeds in real time: not just to record what’s happening, but to understand it.

Cameras become capable of recognizing a worker entering a restricted zone, spotting a forklift too close to a pedestrian, or identifying a missing hard hat before someone steps on site.

Unlike human observers, AI Vision systems never blink.

They run continuously, shifting safety from something that reacts to incidents, to something that prevents them altogether.

Alerts can be triggered before a situation becomes dangerous – using lights, sounds, or automated messages – enabling interventions in real time.

Seeing safety: real-world use cases you will recognize

Across industries, AI Vision is already delivering measurable safety improvements.

Here are four prominent examples:

1. Forklift near-miss detection

In warehouse settings, AI tracks both vehicles and people, alerting teams when proximity thresholds are breached. These events, historically underreported, are now automatically logged, giving teams new visibility and the ability to benchmark across sites.

2. PPE compliance monitoring:

AI systems check for hard hats, vests, gloves, and more, replacing inconsistent spot-checks with real-time enforcement. Sites can also prevent unauthorized entry or trigger alerts for missing gear, increasing compliance and site security.

3. Restricted zone monitoring

Temporary maintenance zones or permanent hazard areas can be dynamically enforced. AI Vision flags any unauthorized entries and can adapt as site layouts evolve.

4. Walkway and emergency exit obstruction

Designated paths and exits can be continuously monitored, ensuring they remain clear to prevent trip hazards or delayed evacuations.

Case study: construction risk visualized

One construction firm implemented AI vision to monitor PPE compliance and detect unsafe proximity between people and heavy equipment.

In just six months at their first site, 145 safety risks were detected, the majority involving workers entering the blind spots of active excavators.

On a second site, the system identified over 300 risk events in just one month, highlighting variance across teams and subcontractors. Perhaps most critically, data revealed a peak in risk within the first hour of operations each day.

These insights enabled the client to implement targeted training and compare risk levels across locations, resulting in more consistent and enforceable safety standards.

Privacy, done right

As with any camera-based technology, privacy concerns are top of mind. AI Vision platforms built with privacy-first architecture address these concerns head-on.

Most systems now use Edge AI, meaning that video data is processed locally – not sent to the cloud – reducing privacy risks and aligning with GDPR regulations.

Analysis is scoped precisely to only what’s necessary, for as long as necessary.

Anonymization tools such as object blurring further protect individuals’ identities, while industry certifications like ISO27001 and SOC2 provide added assurance.

Importantly, many implementations include collaboration with workers’ councils and unions to ensure transparency and build trust across the organization.

AI Vision by industry

AI vision isn’t a one-size-fits-all tool: it’s a highly adaptable solution that supports safety across a wide range of sectors:

a. Manufacturing

AI Vision can reduce manual safety checks by up to 90%, minimize downtime and harm, and lower the risk of regulatory violations.

By connecting safety practices directly to operational KPIs, teams can quantify the cost of non-adherence and improve performance site-wide.

b. Construction

With dynamic layouts and constantly changing site conditions, AI Vision offers a unique advantage: adapting to evolving environments, enforcing PPE rules, and detecting fall risks and intrusions in real time.

c. Logistics

From unsafe pallet stacking to dock door safety and slip hazards, logistics operations benefit from AI Vision’s fast detection and instant alerts. This supports both compliance and the prevention of injuries in fast-paced, high-risk zones.

Getting started: seeing safety is faster than you think

Despite perceptions, deploying AI Vision is extremely straightforward.

Initial assessments, pilot deployments, and value measurement can all happen within days, with many clients seeing ROI quickly by focusing on high-impact areas first.

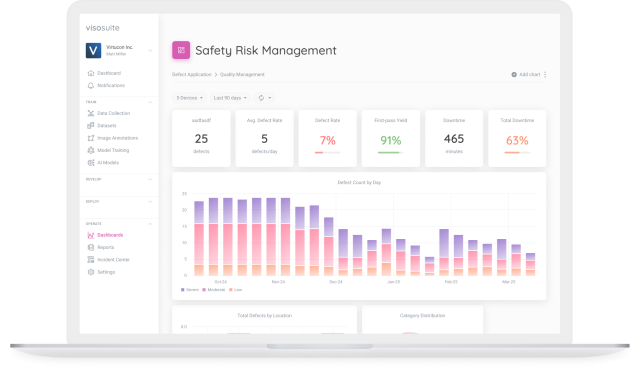

Most systems work with existing CCTV infrastructure, meaning there is no need for expensive hardware overhauls. Off-the-shelf cameras are also supported, and all incident data is accessible via integrated dashboards and incident centers.

The result? A system that provides both real-time intervention and historical insights, without third-party software or complex integrations.

Myth-busting AI Vision

There are plenty of misconceptions and myths about AI vision. We wanted to take the opportunity to set the record straight.

Myth #1: “AI Vision replaces safety teams”.

Reality: The truth is that AI Vision augments them rather than replacing them, freeing staff to act rather than monitor.

Myth #2: “It’s just surveillance”.

Reality: Actually, AI Vision is purpose-built for safety-specific events, not employee oversight.

Myth #3: “It’s too expensive”.

Reality: Most organizations already have the hardware. AI Vision simply builds on that investment.

Myth #4: AI makes too many mistakes.

Reality: Whilst no technology is perfect, AI Vision is more consistent and more reliable than manual checks, especially at scale.

The future: Visual General Intelligence (VGI)

Looking ahead, AI Vision is rapidly evolving into Visual General Intelligence (VGI): the next frontier of visual understanding.

VGI systems go beyond static rules. They recognize context, intent, and flow.

Imagine a system that not only detects a ladder but also knows that it’s in the wrong place – that it blocks an emergency exit – and automatically alerts the team before a violation occurs.

VGI paves the way for:

- Predictive safety analytics

- Open-world visual reasoning

- Integrated robotics and automation

With these advancements, visual intelligence is poised to become a core pillar of workplace safety and operational excellence: not just for compliance, but for transformation.

Secure your free AI Safety Audit

We are also offering a free AI Safety Audit (normally part of our paid pilot programs).

It’s a fast way to see what’s possible on your site, and where AI Vision can deliver the biggest impact. These audits are limited, so you can sign up here to reserve yours.

Stay safe, stay smart – and as always, we’re here to help you see safety differently.