Detect defects, improve safety and track quality on auto-pilot

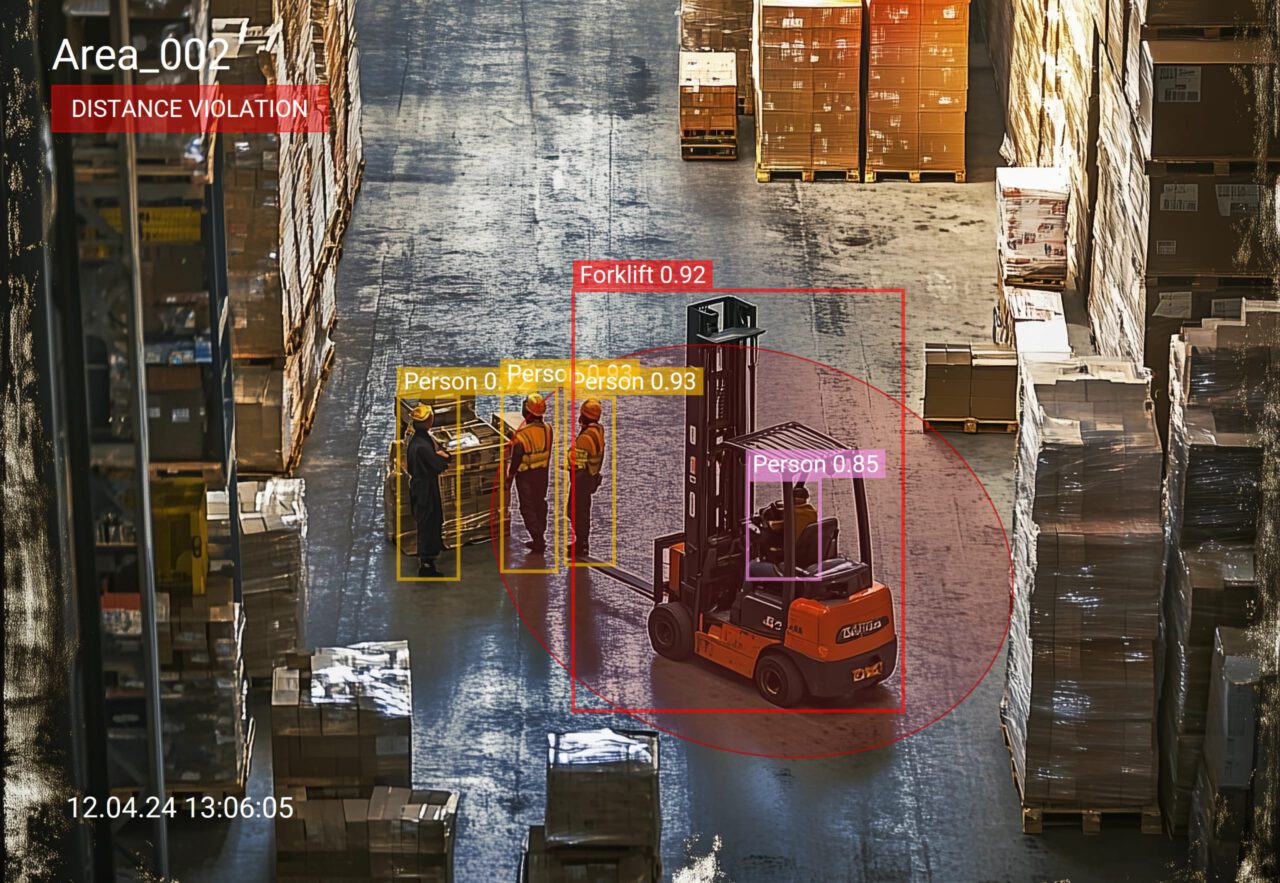

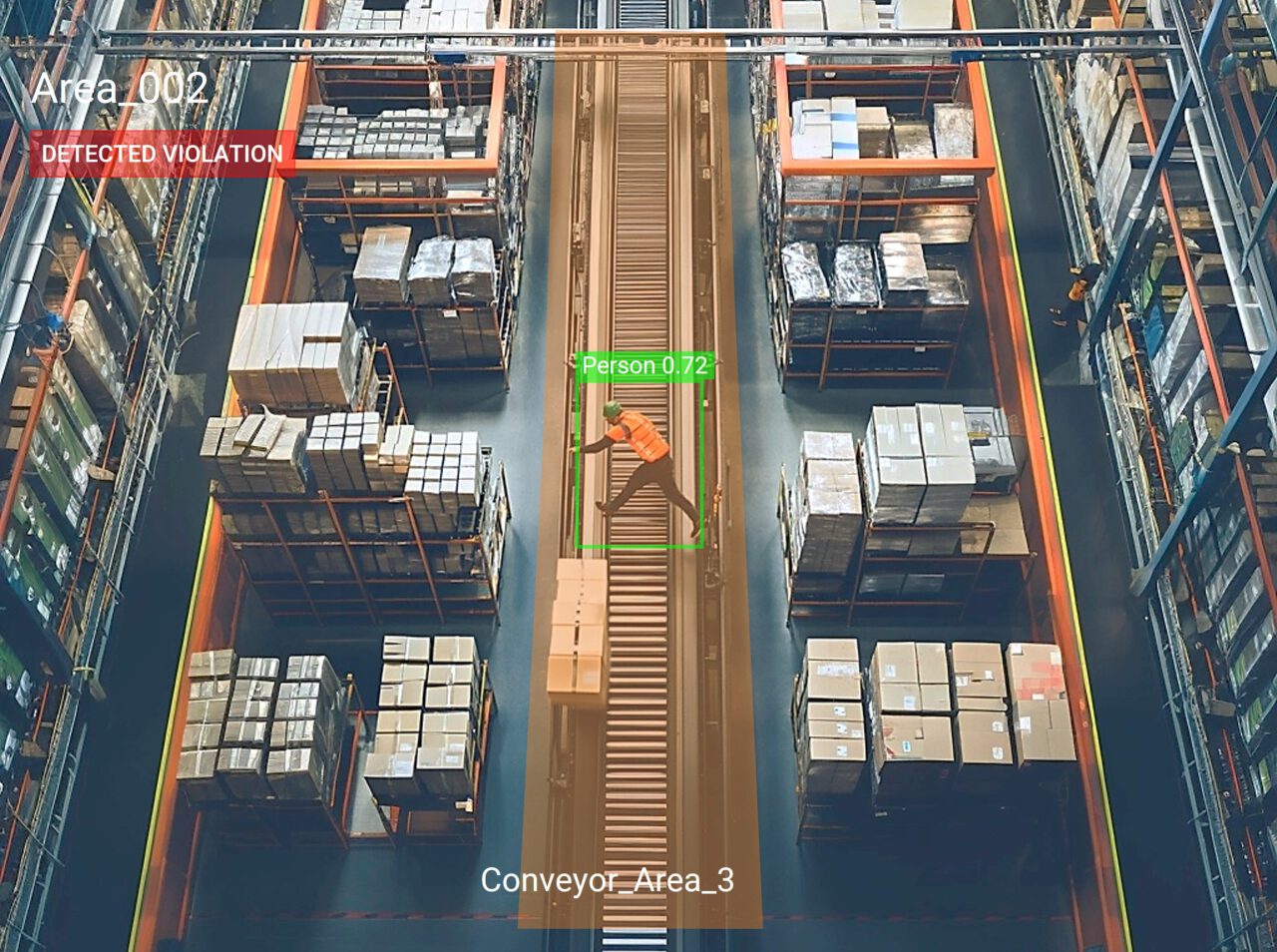

Map your workflows, set custom rules, and automate quality control. Detect defects early, reduce downtime, and improve equipment availability—all in one powerful, easy-to-use system.

Download our short guide to computer vision for manufacturing now!

Value-driven AI. Trusted globally

Our customers are rapidly developing advanced Computer Vision applications with Viso Suite. From global manufacturers to leading construction firms, Viso is trusted by Fortune 500 companies and industry leaders worldwide.

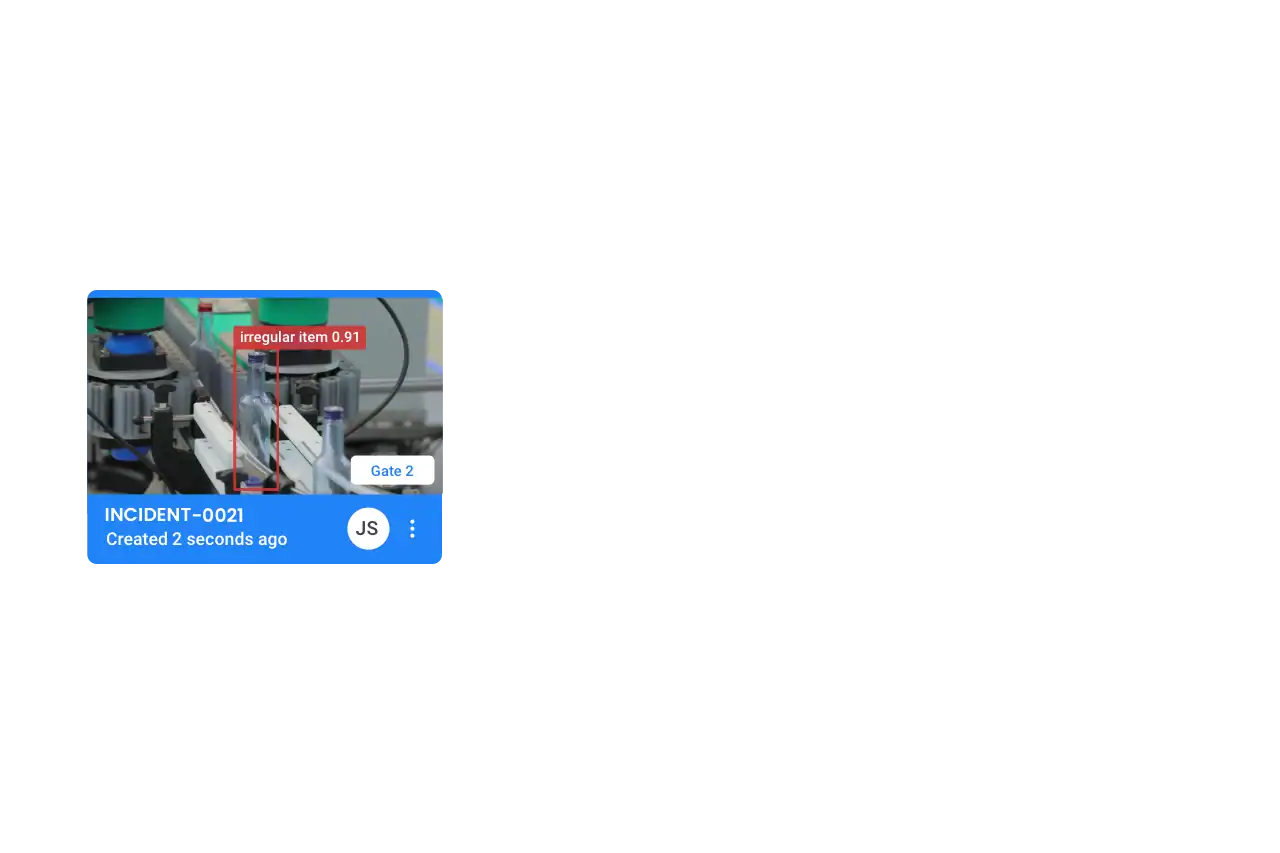

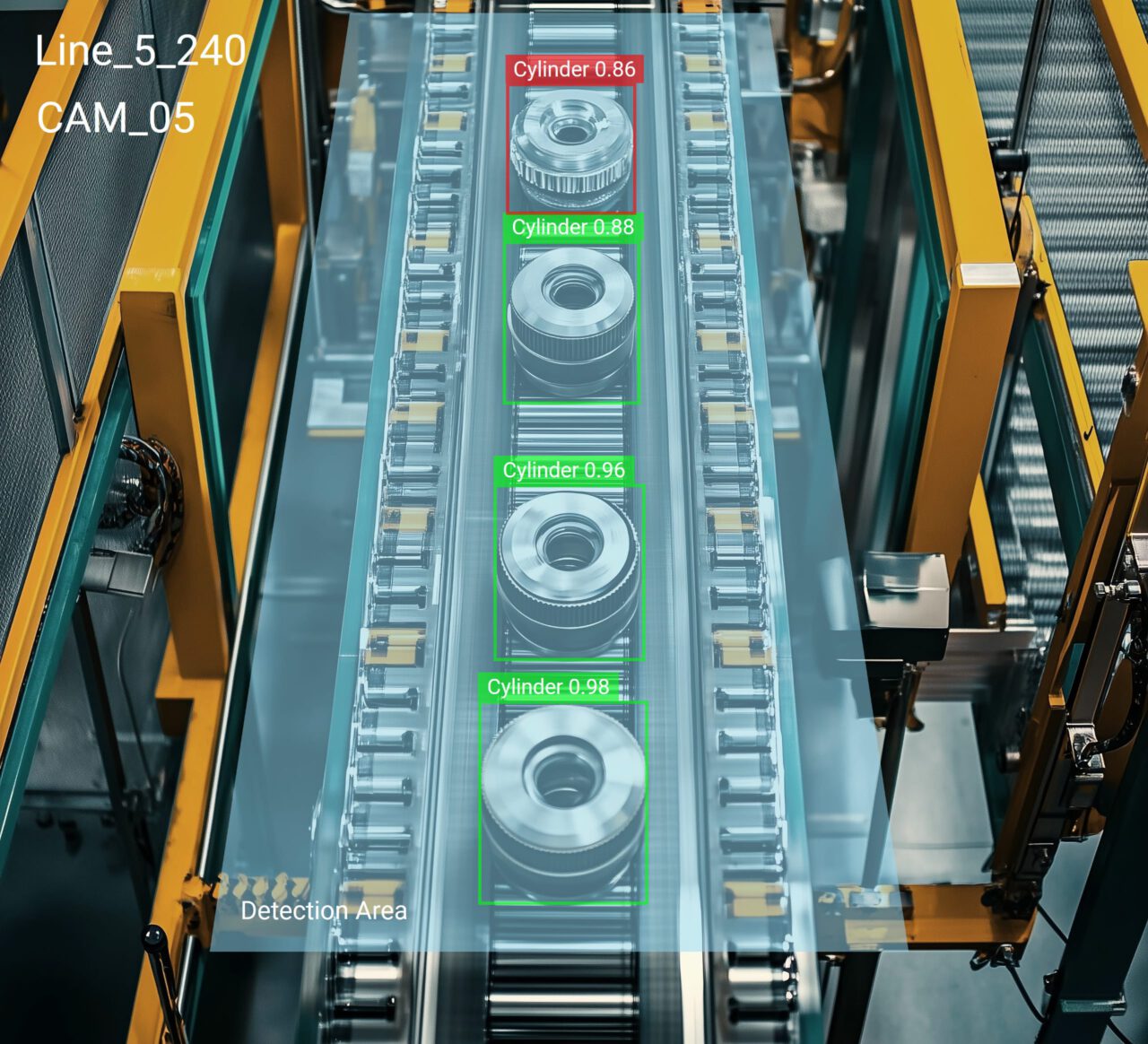

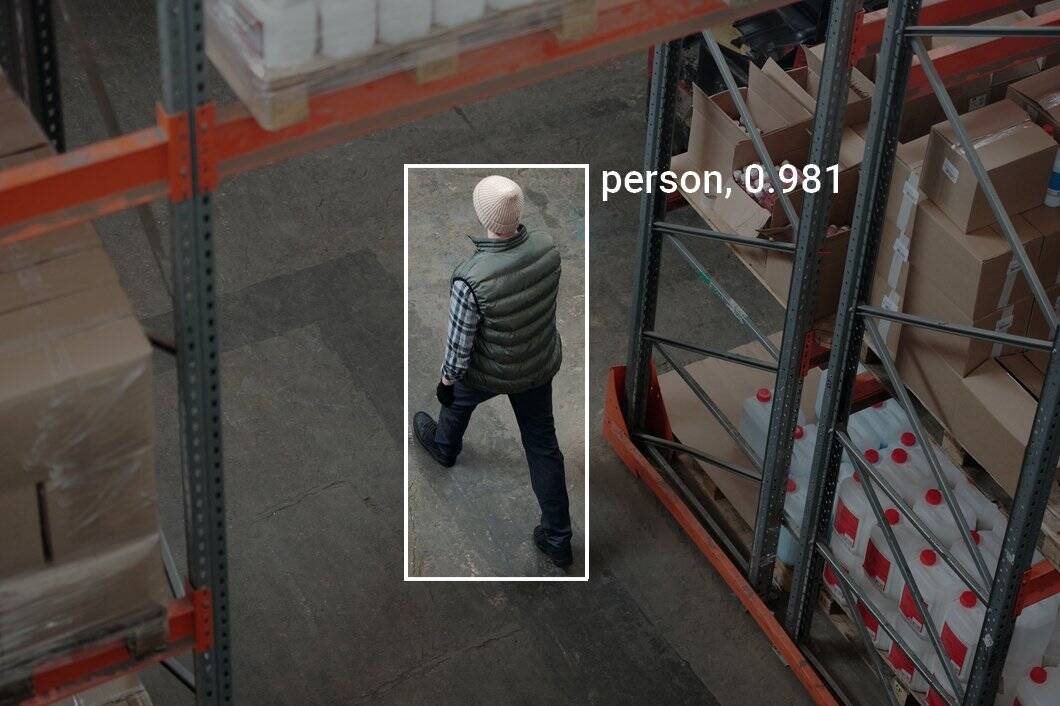

Identify defects on auto-pilot

- Spot bottlenecks in your processes

- Optimize processes to prevent bottlenecks

- Maintain efficient workflows

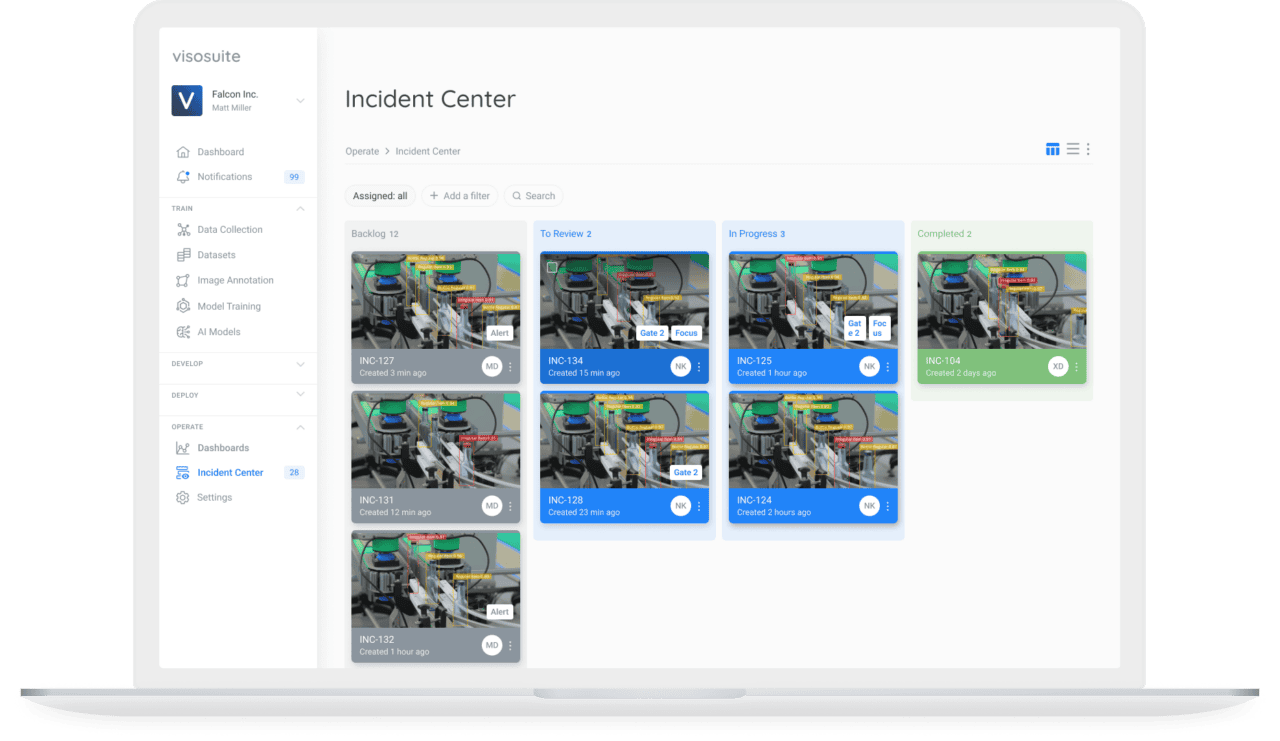

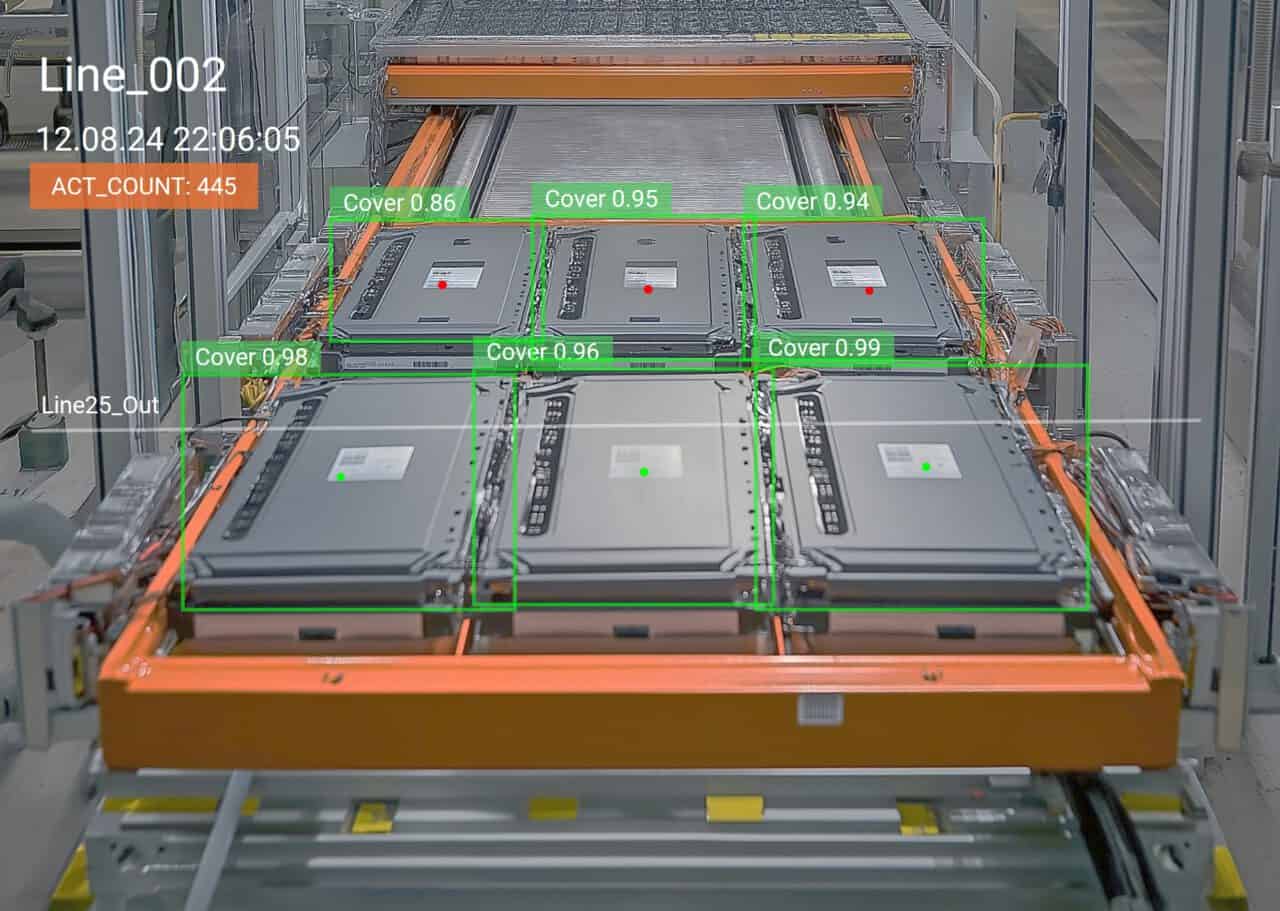

Streamline defect management, from detection to resolution

- Automated quality reports

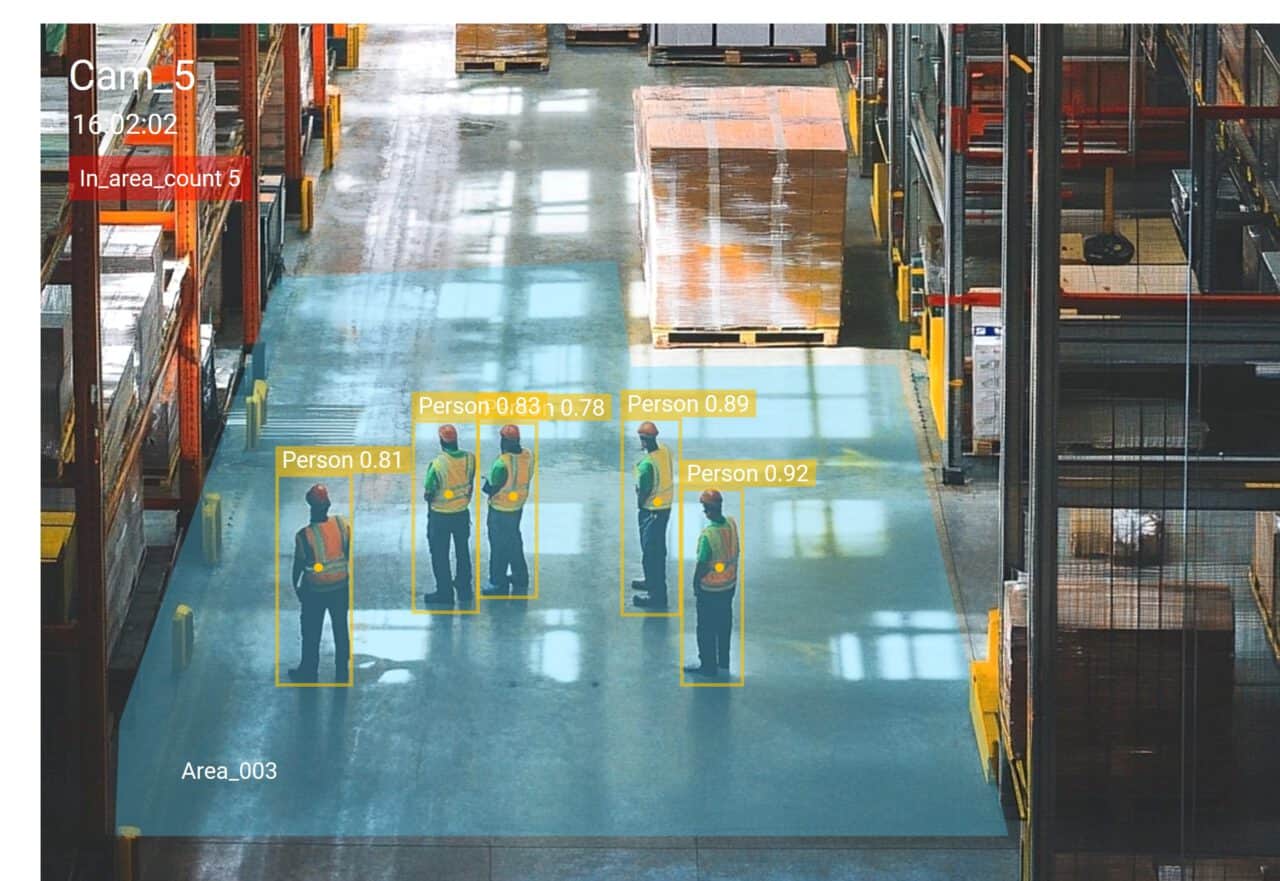

- Incident monitoring and alerting

- Seamless workflow integration

- Quality issue documentation

High-value implementations

Get started with Viso Suite

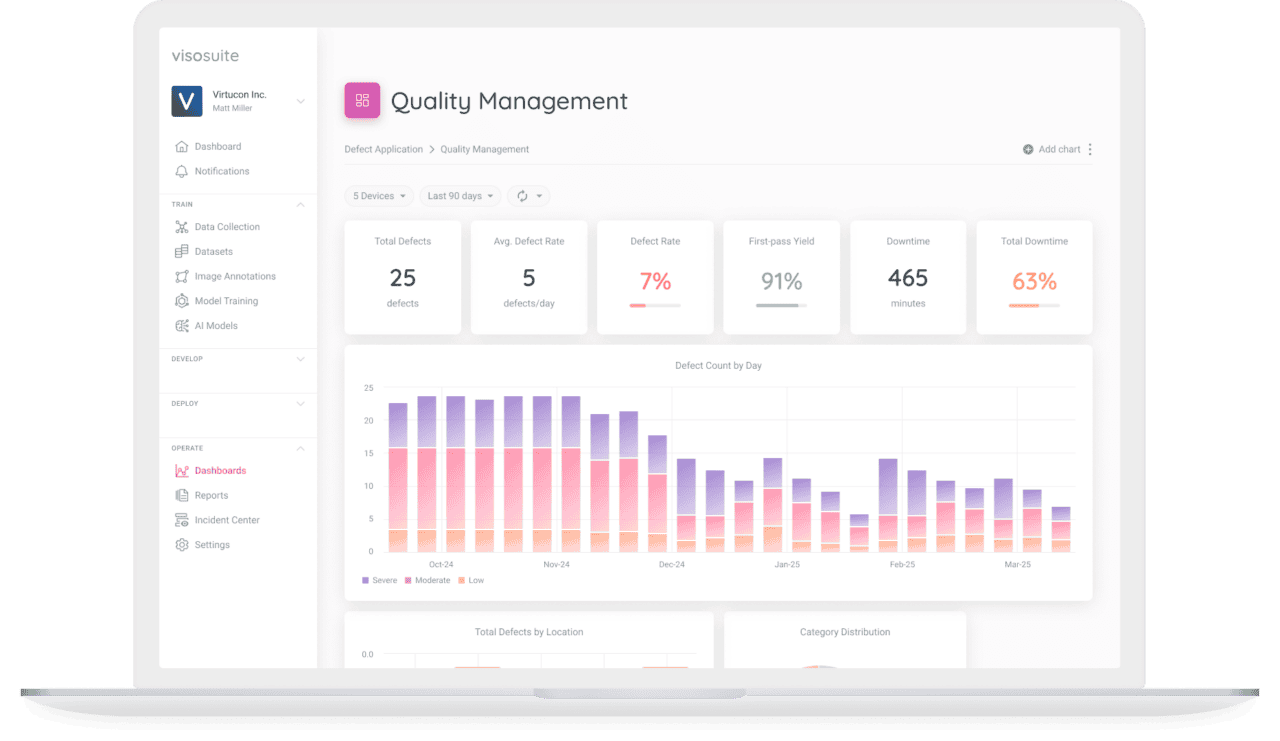

Gain visibility into your operations with real-time KPI dashboard, giving you the information you need to make informed decisions and enabling improvements when it matters.