Heavy machinery and equipment are the backbone of industrial operations. From forklifts and cranes to conveyors and compressors, every piece of equipment must perform reliably, because even small failures can have serious consequences.

Regular inspections are essential to identify wear and tear, prevent breakdowns, and ensure compliance with safety standards. But traditional inspection methods are often manual, time-consuming, and prone to inconsistency.

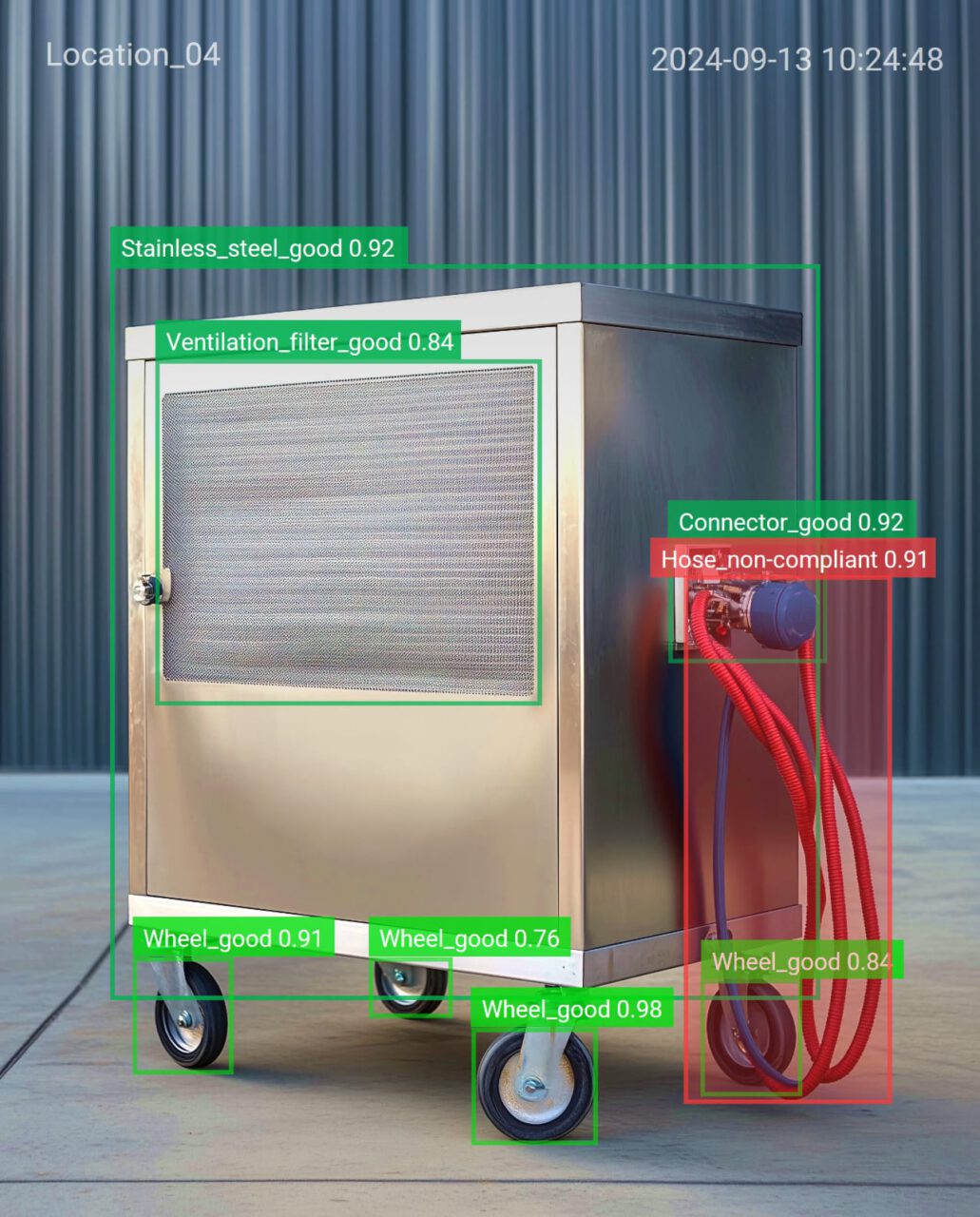

With computer vision, equipment inspection is evolving into a faster, more accurate, and more scalable process, transforming how teams monitor asset health and reduce operational risk.

Why equipment inspections matter

Faulty or uninspected equipment can pose a serious threat to both productivity and worker safety. A malfunctioning brake system, unnoticed fluid leak, or a loose component could cause project delays, accidents, or expensive repairs.

In high-volume environments, daily or pre-use inspections are often rushed, or worse, skipped altogether. Human error, inconsistent documentation, and gaps in oversight only increase the potential for breakdowns.

Computer vision enables organizations to shift from reactive maintenance to a more proactive, data-driven approach while reducing the burden on frontline teams.

What Is visual AI-powered equipment inspection?

Computer vision systems use live video feeds or images to automatically analyze the condition of equipment. Whether it’s a forklift entering a job site, a valve in a pipeline, or a conveyor belt in a factory, AI models can assess key visual indicators of performance and safety.

These indicators include:

- Surface-level damage (e.g., cracks, dents, or rust)

- Loose or missing parts (e.g., bolts, cables, guards)

- Fluid leaks or residue buildup

- Signage visibility and proper labeling

- Wear patterns or abnormal alignment

Using machine learning, the system is trained to recognize normal vs. problematic conditions. If an issue is detected, an alert can be sent in real-time to the appropriate personnel and the inspection automatically logged for audit and compliance purposes.

Real-world applications

Imagine a logistics hub where forklifts are scanned visually before entering the warehouse floor. If a camera detects low tire pressure, a missing safety label, or a damaged light, operations can pause until the issue is resolved—reducing accident risk without needing a manual checklist.

Or in manufacturing, where conveyor belts are monitored continuously for alignment and wear. Instead of discovering a malfunction during production, maintenance teams can act early—minimizing downtime and loss.

Benefits beyond safety

AI-enabled inspections don’t just protect people and assets, they improve operational efficiency across the board.

Some of the core advantages include:

- Consistency: Every inspection is objective and standardized, with no variability between shifts or sites.

- Speed: Visual checks happen in seconds, without slowing down workflows or requiring specialized personnel.

- Traceability: Inspections are automatically documented, supporting compliance with industry regulations and internal standards.

- Cost savings: Early detection of wear and minor faults helps avoid expensive equipment failure or emergency repairs.

Over time, the system learns from patterns in historical data to help teams make smarter decisions about asset utilization, maintenance cycles, and equipment upgrades.

A more scalable approach

Many organizations struggle to scale inspection protocols across multiple sites or fleets. With traditional methods, doing so means hiring more personnel or accepting higher risk.

Computer vision offers a scalable, centralized way to oversee asset health without compromising on quality. Whether your equipment is on a job site, in a facility, or in transit, real-time monitoring and inspection can be managed from a single platform.

Looking ahead

Inspections are no longer just about compliance, they’re a strategic tool for improving uptime, reliability, and workforce safety. As more industries embrace digital transformation, automated inspection with computer vision is quickly becoming the new standard.