Manufacturing

Improve on-site performance by learning about how computer vision can improve both operational efficiency and health and safety.

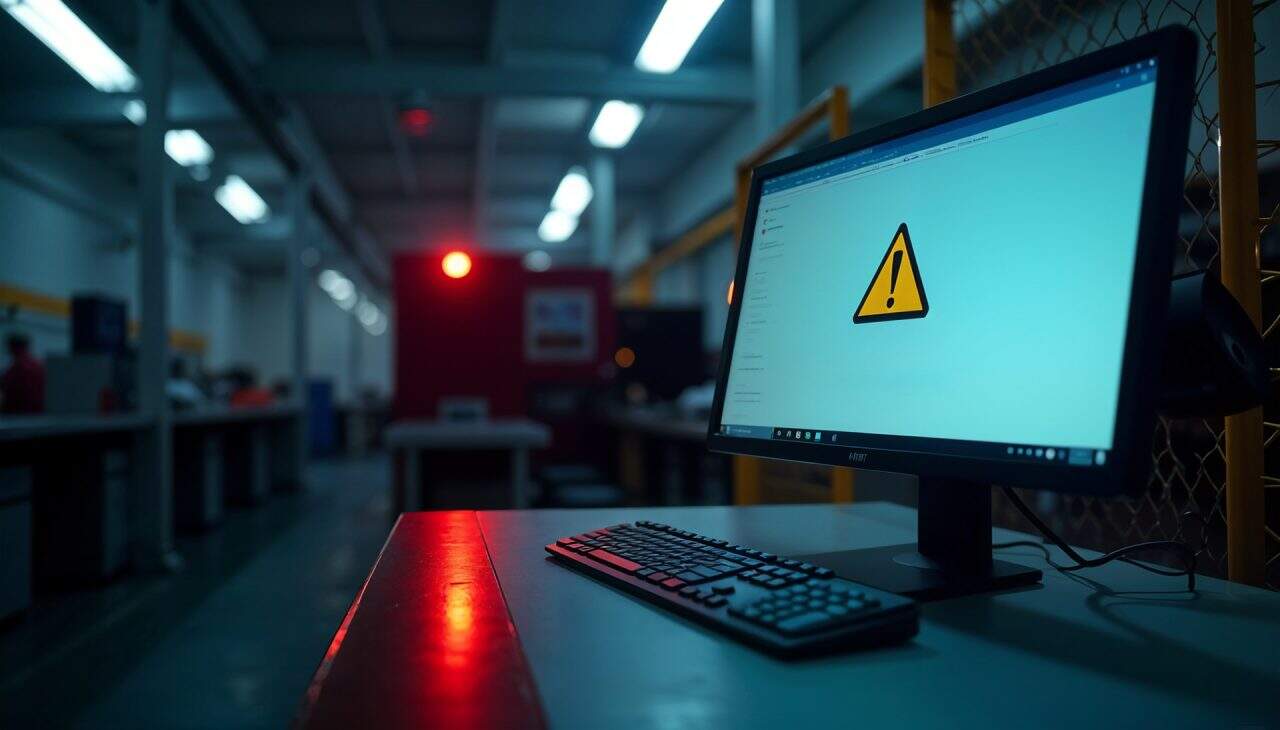

The power of AI Vision: safety alerts for maximum impact

Understand the science and the art of calibrating safety alerts with AI Vision, delivering agile safety monitoring and maximum value.

Visual intelligence: what viso stands for

Computer vision is re-imagining and re-shaping our future, powered by visual intelligence that streamlines operations.

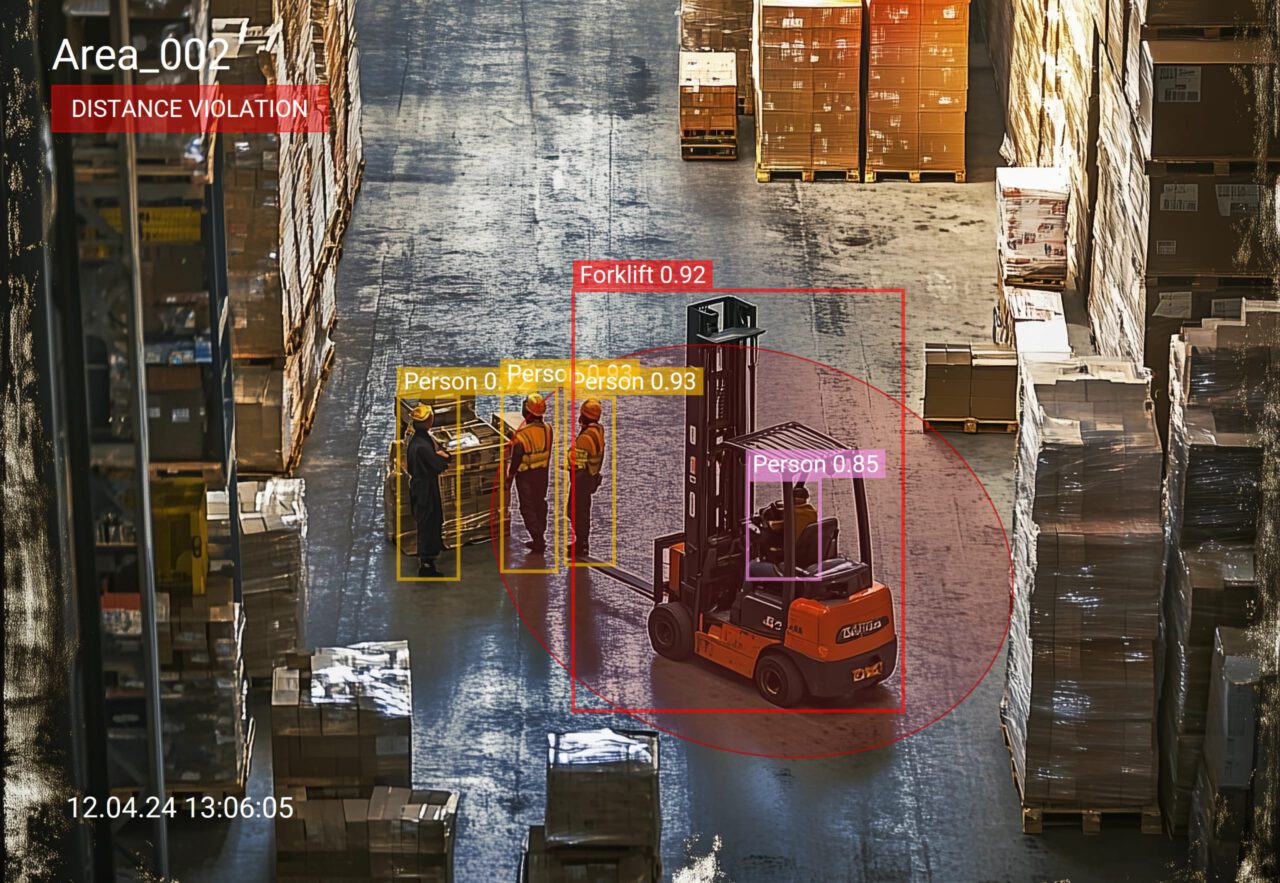

AI Vision on the line: enhancing safety and precision

AI Vision on the line raises the bar for how safe, efficient, and resilient modern industrial operations can be.

High-impact computer vision in supply chain

Firms require real-world AI vision, not experimental concepts. Warehouses are growing, workforces are stretched, and safety is paramount.

Zero downtime, zero harm

Understand how AI Vision is transforming operational safety in the pursuit of zero downtime and zero harm to workers.

Workplace safety and the ‘eyes that never blink’

Elevating workplace safety with computer vision is today easily achievable, by turning on-site cameras into 'eyes that never blink.'

Revolutionizing workplace safety with AI vision

Learn how AI-powered computer vision transforms workplace safety with real-time monitoring, risk reduction, and ROI.

Transforming workplace safety with AI

Explore the impact of enterprise-grade vision AI on workplace safety with real-time risk detection, near-miss logging, and reduced manual inspections.

Unlocking safer operations with computer vision

Learn how computer vision effectively allows HSE teams to augment and strengthen their worksite safety and operations.

Driving safety made possible with computer vision

Vision AI enables manufacturers to monitor vehicle safety, to ensure compliance, reduce risk, and improve site operational safety.

AI vision-powered safety: your ROI accelerated

Unforeseen safety incidents are costing industrial manufacturers as much as $50 billion per year.

Material flow route compliance

Enforcing material flow route compliance is about enabling safer, more efficient operations.