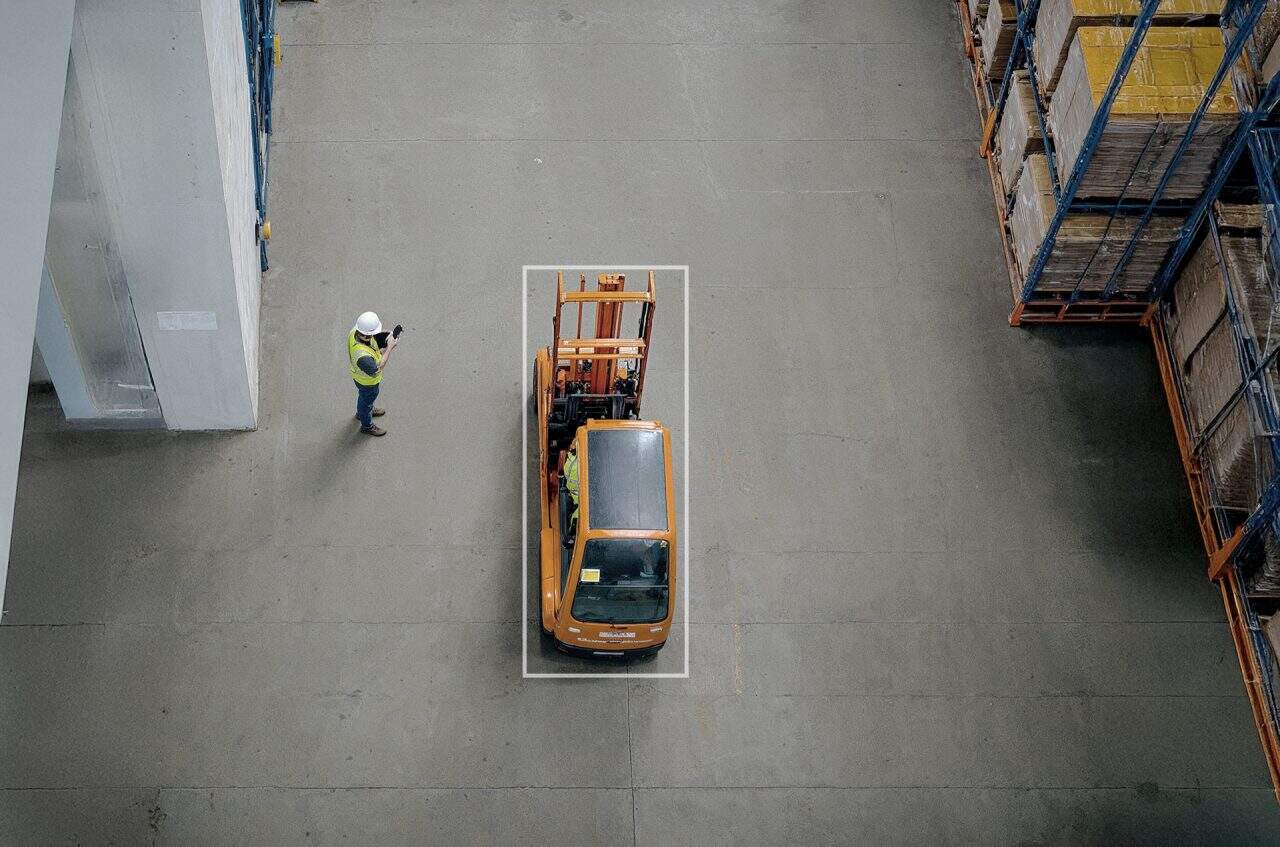

In capital-intensive operations – whether on the factory floor, in warehouses, or across large industrial facilities – mobile assets like forklifts, trucks, and material handling equipment are critical to daily operations. But without accurate visibility into actual in-operation time, organizations risk underusing some assets while overburdening others, leading to inefficiencies and avoidable maintenance costs.

Asset usage optimization through AI-powered computer vision offers a scalable, non-invasive solution to this challenge: providing real-time insights into mobile asset performance, enabling smarter scheduling, and extending equipment life through balanced utilization.

What the system measures

Actual usage time and activity levels of mobile assets across the workday.

Computer vision systems observe operational areas and automatically track when assets are active versus idle. This includes logging hours of movement, identifying periods of non-use, and comparing deployment across similar asset types or shifts.

Key operational metric

Hours of in-operation per day

This metric tracks the actual working time of each asset, compared to its availability and expected usage. The estimated detection value is $200 per month per asset in preventable maintenance costs and efficiency gains through optimized deployment.

How asset usage optimization works

- Real-time visual tracking: Cameras monitor zones where forklifts, tugger trains, or trucks operate – detecting motion, activity start/stop times, and idle periods.

- Operational analytics: AI models analyze data to calculate in-operation hours, identify usage imbalances, and flag anomalies.

- Proactive recommendations: Insights are delivered to operations managers or integrated into asset tracking systems to support workload rebalancing or route adjustments.

- Historical trend logging: Over time, usage patterns are logged and analyzed to uncover recurring inefficiencies or overuse cycles.

This approach provides a complete digital record of asset activity, without reliance on manual logs or additional telematics hardware.

Industry use cases

Automotive manufacturing

- Track forklift utilization across body shops and final assembly

- Identify uneven load distribution between vehicles and reallocate accordingly

Warehousing and logistics

- Monitor actual truck use during shift operations versus planned deployment

- Detect idle zones or underused assets for layout or scheduling optimization

Food and beverage

- Balance use of cold storage material movers to prevent overheating or early maintenance

- Track cleaning and transport vehicles in wet or hygiene-critical environments

Construction and heavy industry

- Measure loader or transport truck run-time across work zones

- Avoid maintenance overspend from over-deployment on specific routes or tasks

Business benefits of asset usage optimization

Prevent overuse and maintenance issues: Identify assets at risk of accelerated wear due to uneven deployment and rebalance workloads accordingly.

Extend asset lifespan: Balanced usage reduces breakdowns and extends service intervals, minimizing unplanned downtime.

Improve capital efficiency: Optimize the performance of assets already on hand before investing in new equipment.

Support smarter scheduling and routing: Understand where and when assets are most in use to build more efficient task schedules.

Build better investment justification: Use real usage data to support decisions on replacements, expansions, or upgrades.

Privacy and system integration

Most computer vision-based systems operate locally on edge infrastructure, ensuring data stays within the facility and meets privacy requirements. They can be easily integrated with existing CMMS (Computerized Maintenance Management Systems), ERP platforms, and digital twin environments to enrich asset management workflows.

This approach is equipment-agnostic, suitable for facilities using legacy or non-instrumented vehicles – and does not rely on GPS or onboard telemetry.

Why asset usage optimization matters

Traditional asset tracking tools provide a limited picture of how equipment is used. Telematics may be missing or expensive to retrofit, and manual reporting introduces inconsistency. As a result, decisions about asset rotation, retirement, or expansion are often based on estimates rather than evidence.

Asset usage optimization fills that gap by turning passive camera infrastructure into a source of continuous, actionable insight. It helps organizations ensure that every asset is contributing effectively, without unnecessary wear or idle time.

With a better understanding of how mobile assets are used day to day, industrial teams can cut costs, improve scheduling, and extend the life of their most important equipment.

It’s not just about monitoring assets: it’s about optimizing how they work for you.