In high-volume manufacturing and logistics environments, productivity is defined by how efficiently materials flow. Delays, slowdowns, or inconsistent movement of products between stations can drastically reduce throughput, even if machines are running and operators are present. But without real-time visibility into flow rate, these slowdowns are often missed or identified too late.

Traditional monitoring tools focus on cycle counts or machine utilization, not the actual rate at which materials move through the process. This creates blind spots that limit optimization and lead to underperformance across shifts or production lines.

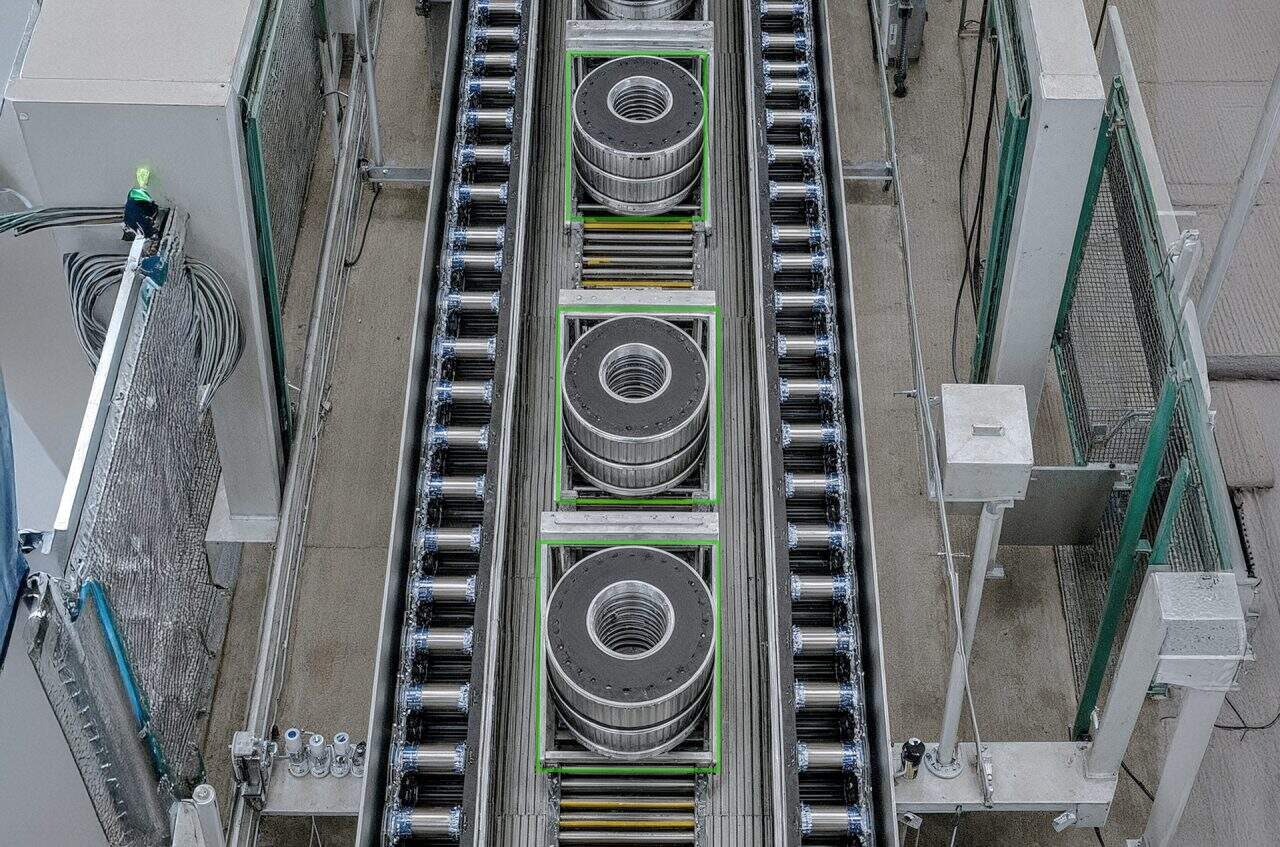

Material flow rate monitoring uses computer vision to continuously measure the speed and frequency at which units pass through key zones. By capturing flow in units per hour, it enables teams to quantify throughput in real time, identify slow-moving areas, and make timely adjustments to improve output.

What the system measures

The number of units passing through defined zones over time, measured continuously.

Computer vision models detect individual items – parts, pallets, products, bins – as they move through monitored flow zones. This data is translated into real-time throughput metrics and compared to historical trends or shift targets.

Key operational metric

Flow rate (units/hour)

A real-time measure of how many units are progressing through a given process area or line segment.

Detection value: ~$5,000/day in additional value for each unit-per-hour increase in flow, driven by higher output and resource efficiency.

How Material Flow Rate Monitoring works

- Zone definition: Flow zones are configured around key transfer points, conveyors, exit points, or work cells.

- Object tracking: As items pass through, the system detects and counts each unit, timestamping movement to calculate velocity.

- Rate computation: The number of units per hour is continuously calculated and trended against historical or planned rates.

- Threshold alerting: If flow drops below expected levels, real-time alerts notify shift leads or line managers for immediate investigation.

- Performance history: All flow data is logged for use in production planning, takt time analysis, and continuous improvement programs.

This non-intrusive system runs on existing camera infrastructure, without requiring sensors or changes to the physical process.

Industry use cases

- Automotive manufacturing: Measure flow of body panels, powertrain components, or finished vehicles through line segments.

- Electronics production: Track unit flow at Printed Circuit Boards (PCB) assembly lines, reflow ovens, or test stations.

- Food and beverage processing: Monitor the rate of bottled, packaged, or wrapped goods across conveyors.

- Warehousing and fulfillment: Measure tote, bin, or carton movement through pick, pack, and ship areas.

Business benefits

Boost throughput in real time: React immediately when flow slows – before targets are missed or delays build.

Improve line balance and station timing: Use flow data to align cycle times between processes and eliminate overproduction or starvation.

Enhance takt time monitoring: Compare actual flow against takt rates to assess performance and drive lean execution.

Reduce downtime and idle time: Identify early signs of blockages, staffing gaps, or equipment issues affecting flow.

Enable data-driven planning: Feed accurate flow data into production planning and simulation tools for better forecasting.

Privacy and integration

All video is processed at the edge. The system logs only anonymized flow data – counts, timestamps, and rates – not personal or identity-related data. It integrates seamlessly with Manufacturing Execution Systems (MES), Supervisory Control and Data Acquisition (SCADA), or Overall Equipment Effectiveness (OEE) systems and can feed dashboards, digital twins, or planning models.

From static counts to dynamic flow optimization

Cycle counts and shift output totals show what happened. Material flow rate monitoring shows how it’s happening right now, providing a real-time pulse of the production process. With this visibility, teams can catch slowdowns early, balance workloads, and incrementally improve throughput hour by hour.

In high-volume environments, every extra unit per hour matters. Flow rate visibility makes it possible to move from reactive output recovery to proactive performance optimization, turning process velocity into a competitive advantage.