It is essential that operators are physically and mentally prepared to safely perform key tasks and duties. This is especially true when working with hazardous machinery.

However, fatigue, illness, distraction or missing PPE can compromise performance and increase the likelihood of error. Traditional readiness checks often rely on verbal check-ins or visual scans, which can be both inconsistent and subjective.

Computer vision introduces a scalable solution to monitor key indicators of readiness, such as alertness, PPE compliance and behavior patterns, crucially all in real time.

Why operator readiness detection still falls short

Human readiness is extremely difficult to measure.

Supervisors may not notice subtle signs of fatigue, and workers may underreport illness due to cultural or operational pressure. PPE checks often happen only at entry, with no follow-up.

In our experience we see that many facilities lack the resources to continuously monitor operator condition, leaving blind spots during critical shift transitions or overnight operations.

Using computer vision to detect operator readiness

Operator readiness failures stem from:

- Fatigue and drowsiness during long or overnight shifts

- Missing or improperly worn PPE

- Unauthorized personnel attempting operation

- Distraction or stress impairing judgment

- Lack of pre-task checks or supervision

Computer vision can automatically detect drowsiness through facial recognition (by blink rate and head nodding, for example), as well as verify PPE presence (gloves, masks, helmets and more), and cross-reference identity to ensure operator authorization.

These checks can be performed at workstations or during log-in procedures to ensure that only prepared and compliant workers engage with critical machinery.

Key metric: readiness alerts per day

Tracking readiness-related alerts provides facilities data to target coaching, optimize shift scheduling, and also identify recurring issues in worker preparedness.

Top 5 business outcomes:

- 50% decrease in fatigue-related incidents (NSC)

- $250,000+ in cost avoidance from reduced errors and injuries (Responsive.io)

- Better shift planning using fatigue trend data

- Reduced absenteeism and presenteeism through early detection

- Improved morale and safety culture with visible support systems

Why it matters: one unready operator can cost millions

An operator who is not ready to control heavy equipment can cause delays, damage or even worse, serious injuries. The NSC reports that fatigue alone contributes to 13% of workplace injuries.

Prevention not only reduces costs but also demonstrates a company’s commitment to worker well-being, which is essential in retention and positive engagement of employees.

The ability to detect readiness gaps before tasks begin shifts facilities from passive oversight to proactive engagement.

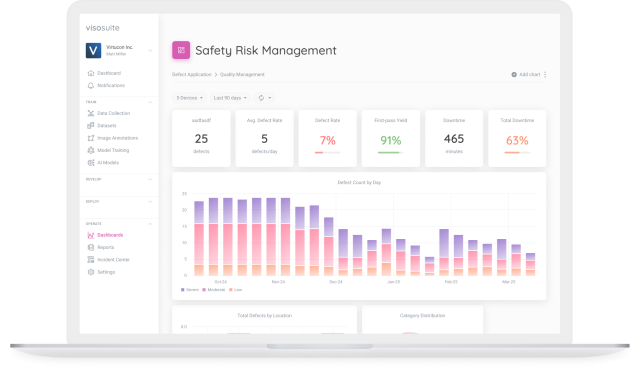

Easy deployment with Viso Suite

Viso Suite leverages existing video feeds to perform readiness checks with no new infrastructure. Detection models run on Edge hardware, preserving privacy and allowing for real-time response.

Administrators can configure alert thresholds, integrate with shift systems and automatically document compliance. The platform can be extended to support badge scans or biometric identity verification for high-security operations.

Proactive safety in operator readiness detection

Operator readiness is the essential cornerstone and foundation of safe manufacturing.

With Viso Suite, facilities can monitor readiness consistently, protect workers from avoidable errors, and optimize team performance through real-time insights.

Computer vision turns a subjective, manual process into an automated set of safeguards that prevent risk and reinforce ownership and accountability.