In manufacturing, equipment like presses, cutters, Computer Numerical Control (CNC) machines and hoists are the backbone of production.

But when these tools are used improperly, due to negligence, fatigue, unauthorized access, or missing Personal Protective Equipment (PPE), they can become dangerous liabilities.

Safety systems like machine guards, safety covers and lockout procedures are vital, but not always followed consistently.

Computer vision offers a new layer of enforcement, allowing facilities to detect unsafe operation behaviors in real time, and take corrective action before injury or downtime occurs.

Why unsafe equipment operation still falls short

Even with safety protocols in place, unsafe use continues to cause accidents. Workers may remove guards, bypass interlocks, or operate machinery while fatigued.

Supervisors cannot oversee every workstation, and violations can occur in seconds. Current detection methods rely on spot checks, incident reporting, or after-the-fact investigations.

This reactive approach leaves significant safety gaps, especially during understaffed shifts or in high-turnover environments.

Using computer vision to detect unsafe equipment operation

Unsafe equipment behavior may include:

- Operating without required PPE (e.g. gloves, goggles, face shields)

- Interacting with machinery in restricted areas

- Bypassing lockout/tagout protocols during maintenance

- Reaching into machines during cycles

- Unauthorized access or untrained personnel operating equipment

Computer vision enables real-time detection by analyzing worker posture, gear and actions relative to machine status.

Systems can identify non-compliant behaviors, trigger visual or audible warnings, and also alert supervisors in real-time.

This ensures that unsafe practices are intercepted instantly and continuously documented for training or compliance purposes.

Key metric: unsafe operation events logged per week

Capturing the frequency of unsafe acts enables safety teams to analyze and monitor trends in behavior and assess operator risk levels. Crucially this allows them to focus interventions where they matter most, delivering tangible, meaningful business outcomes.

Top 5 business outcomes:

- 40% decrease in machine-related injuries after implementation (based on case studies from Civil Engineering journals, Strongarm and SAI)

- $200,000+ in annual savings from reduced downtime and claims (based on case studies from Maxgrip, Mathco and Squadcast)

- Improved audit performance with automated compliance documentation

- Higher operator accountability through data-backed behavior monitoring

- Fewer regulatory citations by proving proactive enforcement

Why it matters: preventing a single unsafe operation

One unsafe action – such as reaching into a running machine – can lead to amputation, fatality, or severe fines. OSHA penalties can reach $15,625 per violation, and injury-related litigation often results in six-figure settlements.

Avoiding just one such incident justifies the investment in proactive detection.

Computer vision transforms safety enforcement from reactive policing to consistent, impartial oversight that protects workers and strengthens compliance.

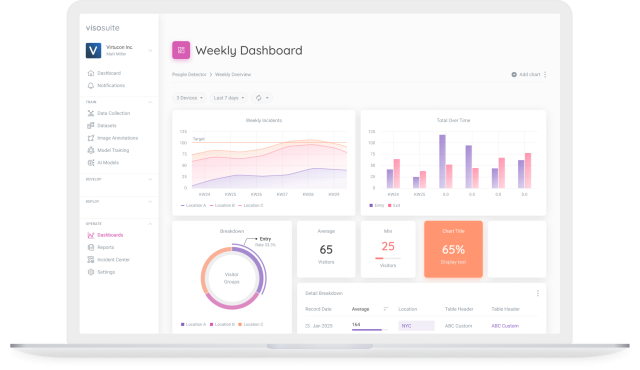

Easy deployment with Viso Suite

Viso Suite connects to existing cameras and overlays detection zones and behavior models tuned to each machine type. PPE detection, zone intrusion, and interaction monitoring can be configured per workstation. Because the solution runs at the edge, it delivers sub-second alerting with no external data transfer, supporting both safety and data privacy.

Viso Suite enables fast onboarding for safety teams and seamless integration with existing safety programs and dashboards.

Proactive safety in unsafe equipment operation

Proactive safety means catching risks before harm occurs. By enforcing safe equipment use through automation, manufacturers eliminate the guesswork and gaps of manual supervision.

With computer vision and Viso Suite, unsafe actions can be caught, documented, and corrected in real time, building a culture where workers know they are protected, and managers know the system has their back.