In many manufacturing and logistics environments, internal vehicle movement is constant. Forklifts, pallet trucks, and automated guided vehicles (AGVs) navigate shared spaces where workers operate in close proximity at the same time.

Speeding – even slightly above limits – significantly increases the chance of collision, injury or damage. Traditional controls like signage or driver training are insufficient in dynamic, fast-paced environments.

With computer vision, manufacturers can now monitor vehicle speed in real time, flag high-risk behavior, and ensure compliance without depending on human supervision.

Why vehicle speeding detection still falls short

Despite posted speed limits and safety policies, enforcement often breaks down in practice. Drivers under time pressure may accelerate in narrow zones. AGVs might malfunction, or be incorrectly or poorly programmed.

Supervisors cannot be everywhere at once, and audits can be rare and often retrospective. Facilities that rely on telematics are limited to certain vehicle types, missing behavior from non-instrumented vehicles or external contractors.

This lack of visibility means unsafe speeds go unnoticed… until an accident happens.

Using computer vision to detect vehicle speeding

Unsafe vehicle operation can occur due to:

- Tight delivery schedules that encourage faster travel

- Poorly marked or unenforced speed zones

- Operator fatigue or over-confidence

- Malfunctioning AGV systems

- Lack of real-time oversight in complex layouts

Computer vision addresses these issues by enabling real-time, zone-specific detection of speeding behavior.

Cameras placed at intersections, loading bays, and pedestrian crossings analyze movement across frames, calculate speed, and identify vehicles exceeding configured thresholds. Unlike vehicle-based sensors, vision works across all vehicle types, even those without onboard electronics.

Alerts can be sent instantly to supervisors, and logs created for later analysis. The system can also distinguish vehicle categories, adjust thresholds per zone, and integrate with broader safety management platforms.

Key metric: speed violations per shift

Tracking the number of detected speeding events during each shift provides insight into policy adherence and potential risk zones. Facilities can correlate violations with incidents, near-misses, or specific operators, enabling targeted intervention.

Top 5 business outcomes of vehicle speeding detection

- 25% reduction in internal vehicle incidents (NIOSH)

- Up to $300,000/year saved in damage and claims from reduced collisions (National Safety Council)

- Faster incident investigations with timestamped footage and violation logs

- Improved shift safety compliance scores in regulated industries

- Insurance premium reductions through documented enforcement and risk mitigation

Why it matters: the cost of a single speeding incident

A single forklift collision can cause tens of thousands of dollars in product loss, equipment damage, and worker injury claims.

According to OSHA, the average cost of a forklift-related injury is $38,000 in direct costs and $150,000 in indirect costs. Beyond costs an incident disrupts operations and can lead to fines, audits or even significant reputational damage.

A proactive approach doesn’t just mitigate legal and financial risk. Rather, it sends a clear message to employees that safety is prioritized and enforced consistently across the facility.

Easy deployment with Viso Suite

Viso Suite enables manufacturers to implement vehicle speed detection without adding vehicle-specific hardware. The platform uses existing IP camera infrastructure and can be configured to monitor specific areas for speed thresholds.

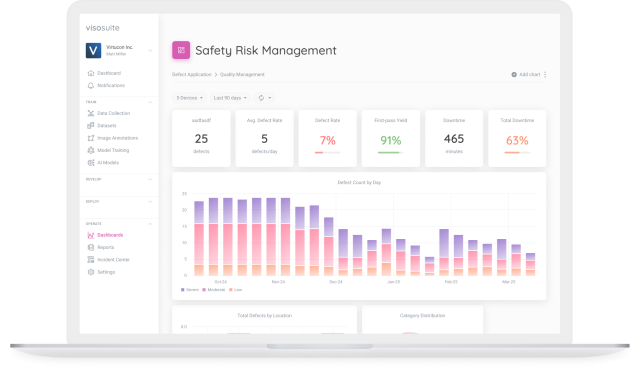

Cameras analyze motion, track vehicle paths, and calculate velocity with high accuracy. Events are logged and accessible through an intuitive dashboard.

Viso Suite operates on edge devices, ensuring fast detection with low latency and preserving privacy by keeping data local. Alerts can be tailored e.g., flashing lights, in-app supervisor notifications, or integration with factory HMI systems.

The solution scales easily across facilities, with central rule management and zone configuration.

Proactive safety in vehicle speeding detection

Speeding near workers is a silent hazard that can escalate instantly into injury or shutdown. By automating detection, companies move from reactive incident response to continuous risk prevention. The result is not just fewer accidents but a stronger, measurable safety culture.

With Viso Suite, manufacturers can eliminate the enforcement gap, ensuring vehicle speed limits are not just set, but actively followed. Real-time data, tailored alerts, and compliance logging make safety scalable and verifiable, without slowing operations.