In high-output manufacturing and production environments, wait times and shift changeover activities are often overlooked yet significant contributors to wasted time and lost efficiency. These routine transitions, whether between tasks, tools, or shifts, can silently drain productivity, disrupt flow, and limit throughput.

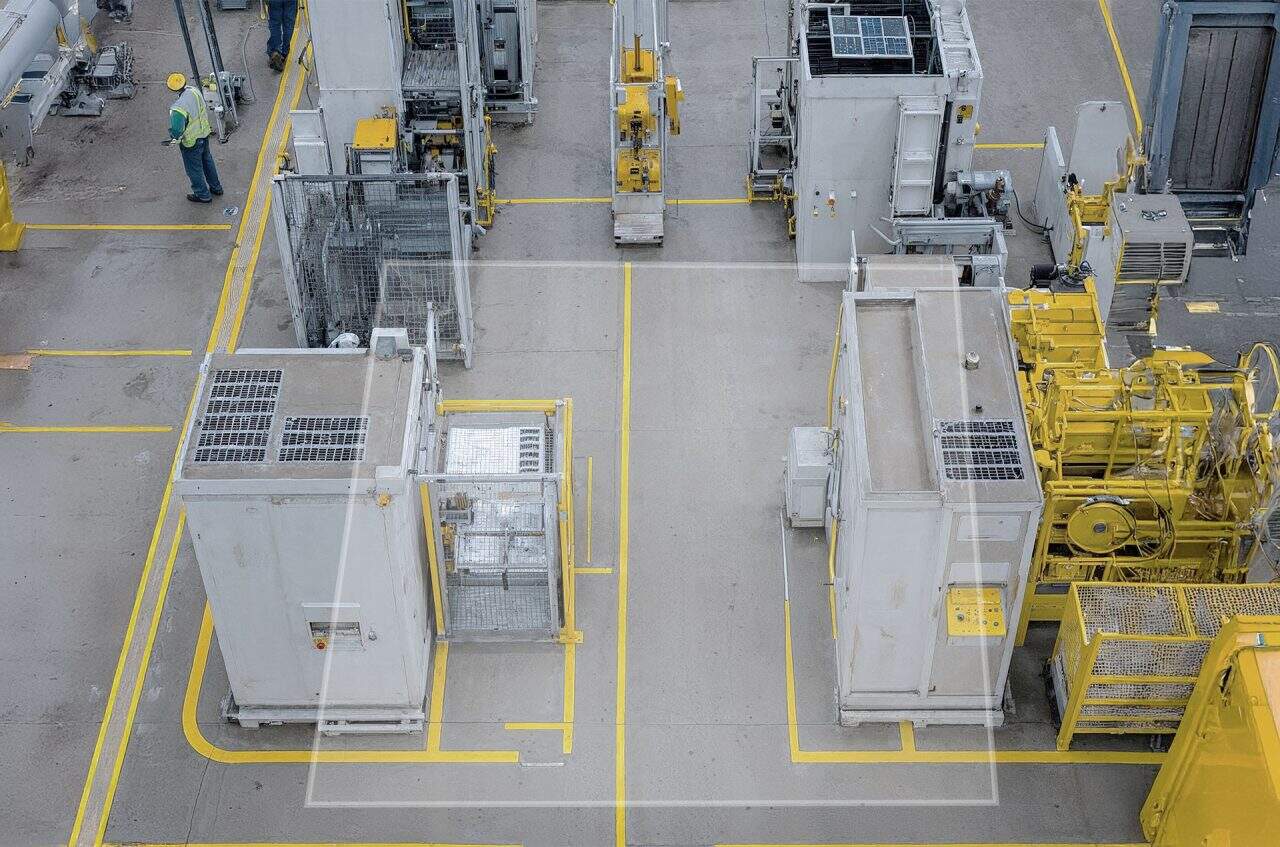

Wait Time and Shift Changeover Logging with computer vision provides an automated, accurate, and non-intrusive method to capture these losses in real time. With clear visibility into when, where, and why delays occur, organizations can optimize processes, reduce waste, and drive lean transformation across operations.

What the system tracks

Delays, transitions, and handoffs that interrupt production continuity.

Computer vision systems monitor real-world activities through on-site cameras, logging every instance of waiting or changeover activity. This includes moments when operators are idle due to missing materials or instructions, as well as shift handovers and equipment transitions.

Key operational metric

The minutes of wait/shift metric represents the total non-productive time recorded per shift across teams or equipment. The estimated impact per event is $200 per hour in lost productivity due to idle time or inefficient transitions.

![]()

How Wait Time and Changeover Logging works

- Visual detection of delay events: AI models interpret camera footage to identify when operators are idle, tools are being changed, or equipment is transitioning between production states.

- Time-stamped logging: Every delay or changeover is recorded with precise timing data for review and analysis.

- Configurable thresholds: Users can define maximum allowable wait periods or standard changeover durations to benchmark performance.

- Real-time alerts: If delays exceed target thresholds, supervisors are notified to investigate or assist.

The system runs passively in the background, requiring no manual input—ensuring unbiased and continuous monitoring.

Use cases across industrial operations

Automotive and assembly

- Log shift changeovers and identify excessive setup delays between model variants

- Capture tooling or fixture change times that extend beyond lean standards

Electronics manufacturing

- Track SMT line downtime during component changeovers

- Identify operator wait periods caused by missing parts or unclear instructions

Pharmaceutical and batch production

- Monitor clean-in-place (CIP) procedures during batch transitions

- Detect quality hold times and delays due to documentation or review processes

Mixed-model manufacturing

- Compare shift-to-shift transitions across teams or lines

- Detect inconsistencies in setup procedures across similar production scenarios

![]()

Business benefits of Wait Time and Shift Changeover Logging

- Eliminate hidden time losses: Identify small delays that add up over the course of each shift, freeing up capacity without capital investment.

- Improve shift performance: Compare transitions across teams and lines to identify high-performing practices and training opportunities.

- Enable Lean and TPM initiatives: Support continuous improvement with precise, objective data on downtime and NVA (non-value-added) activities.

- Enhance scheduling accuracy: Use real-world changeover durations to better align production plans and improve schedule adherence.

- Drive process standardization: Highlight variation in execution to support SOP alignment and consistency across operators.

Privacy and integration considerations

AI vision systems typically operate on edge devices, ensuring video and activity data stays local for privacy and performance. Logged metrics and alerts can be integrated with existing MES, ERP, or operational dashboards to provide unified visibility across the plant floor.

Deployment can be tailored to specific zones – such as work cells, maintenance bays, or shift muster points – without requiring deep infrastructure changes.

From manual estimates to real-time clarity

Traditional tracking methods for wait times and shift changeovers rely on logs, operator memory, or stopwatches. These approaches are often inconsistent, delayed, and subject to reporting bias, making it difficult to pinpoint opportunities for true process improvement.

Wait Time and Shift Changeover Logging replaces guesswork with real-time, objective data. Teams gain the clarity needed to reduce transition friction, align shift expectations, and uncover the root causes of idle time that diminish productivity.

By systematically capturing non-value-added time, manufacturers can target waste, improve coordination, and build high-performance shift cultures.

Wait Time and Shift Changeover Logging is a foundational tool for lean operations and a competitive edge in efficiency-driven industries.