Key insight: unlocking safer operations

Companies adopting computer vision (also known as Vision AI) are unlocking safer operations, reducing critical safety incidents – such as PPE violations, forklift collisions, and restricted area intrusions – by up to 75%. These gains are achieved through real-time, automated monitoring using existing video infrastructure.

Safer operations: why it matters

Fewer incidents mean fewer injuries, less downtime, and lower compliance risk, translating into significant cost savings and more resilient, safer operations. For HSE leaders under pressure to meet zero-harm goals while improving efficiency, Vision AI is emerging as a transformative tool.

Why safety executives are turning to AI Vision

In high-risk, high-output industries, where operational uptime is critical and safety failures carry significant financial and human costs, the pursuit of safer operations has reached an inflection point.

Unplanned downtime and workplace incidents cost US manufacturers over $50 billion annually (Forbes). The call for safer operations and zero-harm environments is louder than ever and increasingly important.

Yet, traditional approaches—relying on manual audits, paper-based tracking, and reactive investigations—are often too slow or limited in scope to keep up with the demands of modern industrial environments. This is where Vision AI is redefining the safety playbook.

Measurable impact: the financial and human ROI

Unlike manual spot checks, which are periodic and prone to human error, Vision AI never blinks. As a result, organizations adopting Vision AI have consistently seen substantial improvements in key safety metrics:

- PPE non-compliance reduced by 55%

- Near-miss events down by 60%

- Restricted zone intrusions cut by 75%

- Forklift collisions reduced by 50%

For a typical mid-sized industrial organization – like the composite case study featured in our Health & Safety whitepaper – this translates to over $628,000 in annualized savings, as well as:

- Gains in productivity

- Insurance premium reductions

- Minimized compliance exposure

Crucially, these aren’t just numbers. Every incident prevented is a worker protected, a shift kept on track and an investigation avoided.

From static surveillance to proactive intelligence

Many industrial facilities are already blanketed with video surveillance. However, these systems often function as passive observers: valuable only after an incident has occurred.

Vision AI shifts this paradigm by transforming existing camera infrastructure into real-time, intelligent monitoring systems. Think of it as a second set of eyes enhancing situational awareness, offering 24/7 support to stretched safety teams.

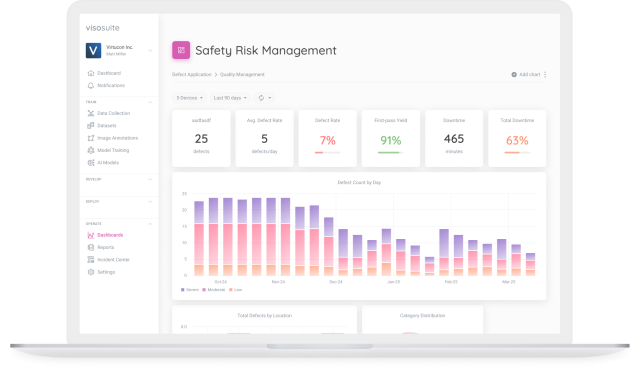

By applying advanced computer vision algorithms, Vision AI continuously analyzes video feeds to detect safety risks as they unfold. It recognizes patterns of unsafe behavior, identifies compliance breaches like missing PPE, and flags near-miss events long before they escalate into recordable incidents.

Augmenting safety culture, not replacing it

Vision AI is not about replacing human judgment: it’s about augmenting it.

While frontline teams and safety officers will always be essential, AI enhances their capabilities by offering real-time alerts, objective data, and automation of routine tasks. By capturing every incident and anomaly with timestamps and contextual metadata, Vision AI builds a centralized safety data layer.

This allows organizations to move beyond isolated events and see patterns:

- Where are the hotspots for risk?

- Which shifts see more incidents?

- Where is retraining needed?

Over time, these insights support continuous improvement.

Safety interventions can be precisely targeted, and the impact of corrective actions can be verified with hard data. With Vision AI there is no longer any need for reliance on guesswork and estimation.

Reducing administrative load and ISO compliance risk

Industrial safety doesn’t end with incident prevention: it also involves meticulous documentation, regulatory audits, and contract qualifications. Vision AI eases this burden by automating compliance checks and generating digital audit trails.

This has significant and far-reaching implications for HSE leaders.

In competitive environments, being able to demonstrate high standards of safety performance with concrete, real-time evidence can be the deciding factor in passing third-party audits, avoiding costly fines and even securing long-term contracts.

Compliance with ISO standards (such as ISO 45001 (occupational health and safety) and ISO 9001 (risk management and continuous improvement)) are essential, internationally recognized requirements. Covering various aspects of quality, safety, and efficiency, they provide a framework for improving processes, building trust, facilitating trade and more.

Read more: viso.ai is ISO 27001 certified, underscoring our commitment to upholding the security, confidentiality, integrity, privacy and availability of customer data in Viso Suite. Learn more about how we prioritize security in Viso Suite.

Safer operations: fast deployment, scalable impact

Another of the key advantages of Vision AI is its ability to integrate seamlessly with existing infrastructure. Rather than requiring an overhaul, most systems can leverage the cameras already installed on-site.

Deployments typically begin in high-risk zones – such as forklift lanes, entry points, or hazardous material areas – and scale across facilities based on results. This phased rollout minimizes disruption and delivers early wins that build momentum.

For many organizations, full multi-site implementation can be achieved in under ninety days. Because the system integrates with commonly used EHS and MES platforms, IT overhead is minimal and change management is streamlined.

The road ahead: smarter, more sustainable and safer operations

As safety leaders look to meet escalating demands – tighter regulations, more complex operations, and a sharper focus on ESG – tools like Vision AI offer a compelling edge.

They deliver not just compliance, but resilience. Not just visibility, but foresight.

Vision AI enables a proactive safety culture, where risks are addressed in real time and continuous improvement is driven by data.

In an era where spending on safety is often expected to show a return – and every missed incident is a missed opportunity to prevent harm – this powerful and scalable technology delivers meaningful results.

Final thought

Industrial safety isn’t just a compliance requirement: it’s a competitive advantage.

Vision AI gives safety executives the tools to protect their people, optimize their processes and elevate their performance across the board.

In short: fewer injuries, fewer disruptions, fewer costs – and a lot more confidence.

Unlocking safer operations with Vision AI is now clearly here to stay.