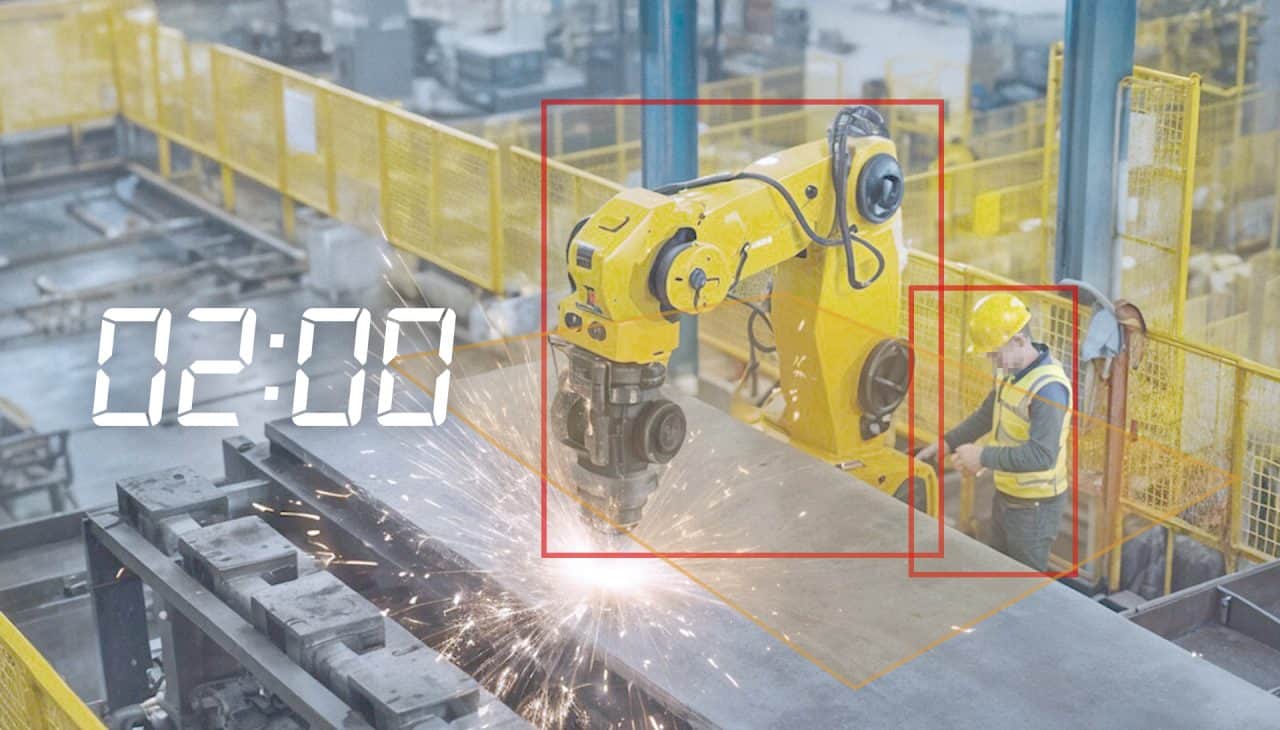

In the world of industrial safety, preventing accidents before they happen is essential. Timing isn’t just important – it’s everything. Research shows that most workplace accidents can be traced to hazards overlooked just minutes before impact. Experts call this the critical intervention window: the short time where proper action can prevent a near-miss from becoming an incident.

Yet traditional safety systems are designed to react after something happens, rather than preventing accidents. Reports, investigations, and corrective actions come too late to stop harm in real time, before accidents happen. The result: safety leaders are often left asking, “What went wrong?” rather than “How did we stop it?”.

With a fatal work injury rate of 3.5 per 100,000 workers, and one worker death every 99 minutes, the importance of prevention timing could not be clearer. The question is no longer whether incidents can be prevented, but how fast hazards can be identified and addressed before the window closes.

Why worker-only safety systems fall short of preventing accidents

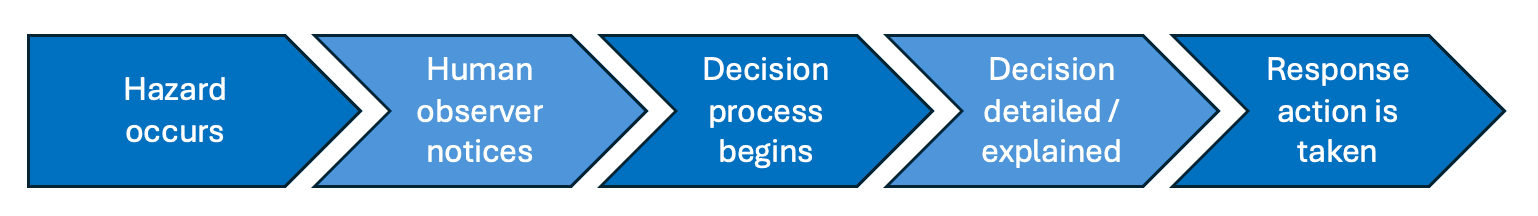

The traditional safety response chain looks like this:

Even with well-trained teams, this sequence often takes too long. By the time hazards are reported, communicated, and escalated, the two-minute window has passed.

There are three key limitations of worker-only safety oversight:

- Attention fatigue: workers miss critical cues during long shifts or when multitasking

- Delayed reporting: a forklift operator sees a spill but finishes their task before reporting it, or a supervisor notices unsafe behavior but is tied up elsewhere, delaying their reaction time.

- Coverage blind spots: you can only be in one area at a time , meaning entire sections of a site may be unmonitored until after an incident occurs.

This makes most traditional systems re-active by design. They capture data about what happened but rarely act fast enough to stop it from happening.

Preventing accidents by operating inside the critical window

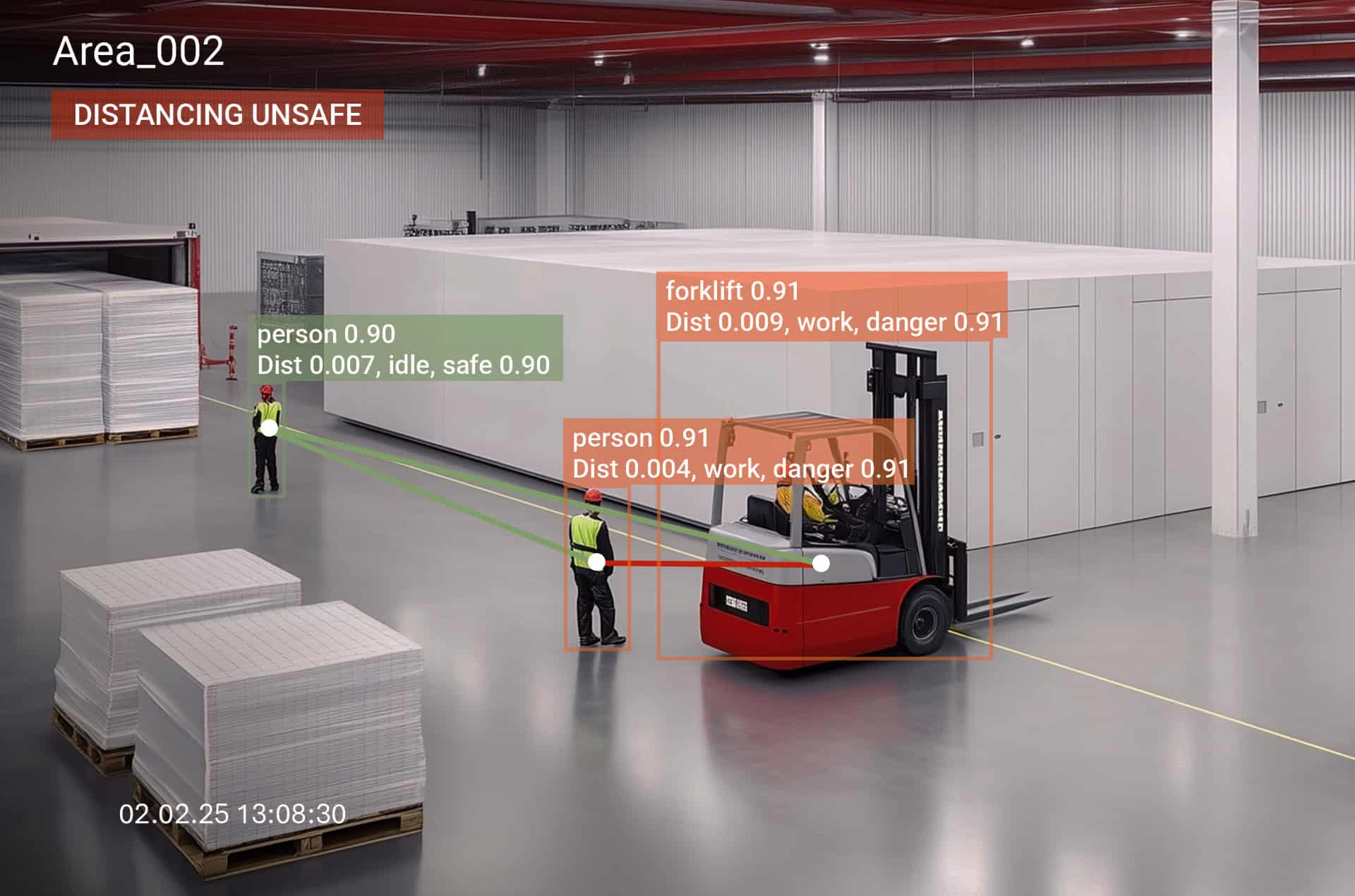

Using AI Vision changes the equation by shifting from reaction to prevention. Unlike human observation, computer vision systems function in real time – detecting hazards as they emerge, not after.

- Instant detection: AI Vision identifies anomalies like spills, machine malfunctions, forklift blind spots, or PPE violations the moment they appear

- Automated alerts: when risk thresholds are exceeded, alerts are sent immediately to supervisors or workers in the affected area

- Multi-parameter analysis: systems track PPE compliance, unsafe behaviors, and environmental conditions simultaneously, spotting patterns invisible to human eyes

The result: organizations regain the two minutes that matter most.

Instead of waiting for human recognition and reporting delays, AI Vision gives safety teams immediate visibility and time to act. This isn’t just faster monitoring – it’s a fundamentally different approach. Safety moves at machine speed instead of human speed.

Proof in numbers: preventing accidents pays

The impact of operating within the 2-minute rule is already measurable across industries:

- Companies in manufacturing, transport, and food distribution report up to 80% reductions in near-misses and incidents after adopting computer-vision-based predictive safety analytics

- Response times cut from minutes or hours to seconds through AI-powered alerts

- 17% higher productivity achieved by organizations with prevention-first programs, as fewer incidents mean less downtime

- Insurance carriers increasingly reward AI-driven safety programs with preferential rates, recognizing the lower risk profile

The economics are equally compelling. The cost of preventing accidents – by investing in AI Vision systems – is a fraction of the cost of even a single serious incident. Workers’ compensation claims, investigation costs, downtime, and reputational damage quickly outweigh any upfront investment. By operating inside the critical window, AI Vision transforms safety from an unavoidable cost into a profit-protecting strategy.

From re-active to preventive: a cultural shift

Perhaps the greatest change brought by the 2-minute rule isn’t technological – it’s cultural. Traditional safety culture revolves around incident analysis: reviewing reports, determining fault, and adding corrective measures. But with AI Vision, the focus shifts to what never happens because risks are addressed before they escalate.

- For workers: confidence grows when technology actively protects them, instead of passively recording failures (they see AI Vision as a partner in safety, not a surveillance tool)

- For managers: resources shift from incident investigation to continuous risk mitigation (instead of firefighting, leaders spend time building stronger safety systems)

- For executives: safety metrics transform from lagging indicators (injuries, claims, fines) into leading indicators (near-misses prevented, risks eliminated)

This cultural shift builds trust and resilience across the organization, reinforcing that safety is not just compliance, but a proactive commitment to prevention.

The economics of the 2-minute rule

Every incident prevented represents a cascade of avoided costs:

- Workers’ compensation and claims administration

- Investigation and reporting time

- Production downtime

- Legal and reputational risk

AI Vision systems prevent these expenses by ensuring hazards are detected and addressed before accidents occur. In doing so, they make zero harm not just an aspirational goal, but an achievable strategy.

For safety leaders facing the pressure of limited resources, rising regulatory demands, and relentless operational targets, the 2-minute rule offers a clear path forward: operate within the window where prevention is possible.

The 2-minute rule reframes what’s possible in industrial safety. AI Vision doesn’t replace human professionals – it amplifies their impact by ensuring no hazard goes unnoticed during the critical intervention window.

The result is fewer incidents, safer workplaces, and stronger business outcomes. In an environment where every second counts, Using AI Vision ensures safety leaders can act not after the fact, but before disaster strikes.