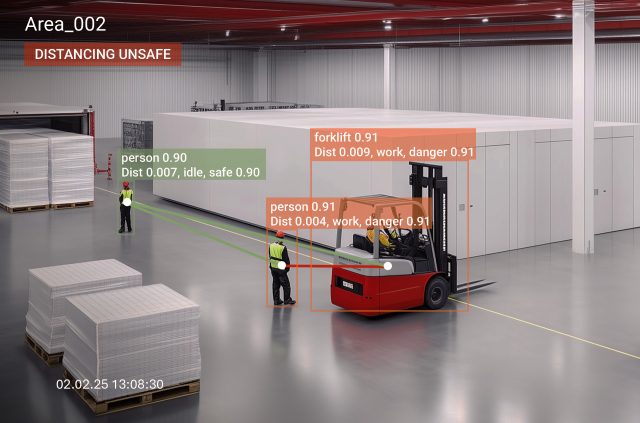

Computer vision (also known as AI Vision) has revolutionized safety alerts and monitoring across industries: from preventing vehicle collisions in warehouses to detecting PPE violations on construction sites. As organizations harness this powerful technology, one strategic question emerges: how do you calibrate your AI to deliver maximum safety value?

The answer lies in understanding that safety alerts aren’t just notifications: they’re strategic tools that can be precisely tuned to match your operational priorities and risk tolerance.

Safety alerts: the science and art of monitoring calibration

For safety professionals in industries like manufacturing, logistics, construction, and retail, AI Vision offers unprecedented visibility into operations. You might consider them to be like ‘eyes that never blink‘. The key to success lies in calibrating systems to strike the right balance between comprehensive coverage and operational efficiency.

This calibration represents both the science and the art of making AI Vision work optimally for specific environments.

Understanding safety alert sensitivity: a strategic choice

Modern computer vision systems offer remarkable flexibility in how they detect and report incidents. This adaptability means users can strategically tune their safety alerts based on what matters most to their operation:

- High-sensitivity detection captures more potential incidents, ensuring comprehensive coverage of safety-critical areas

- Precision-focused detection prioritizes accuracy, reducing interruptions while maintaining oversight of the most critical events.

The power lies in having this choice, and the ability to adjust it as needs evolve.

When maximum vigilance delivers maximum value

Certain environments benefit tremendously from comprehensive alert coverage:

Safety-critical zones

In areas with moving machinery or hazardous materials, extensive monitoring creates multiple layers of protection. Each safety alert represents a potential intervention opportunity.

Anomaly detection applications

In logistics and manufacturing, detecting subtle variations – like items placed outside designated areas or unexpected personnel movement – requires sensitive monitoring that captures nuanced changes.

High-consequence environments

Where a single missed incident could result in serious injury or significant operational disruption, comprehensive alerting provides invaluable peace of mind, on a path to zero downtime and zero harm.

In these scenarios, frequent safety alerts represent the system’s strength: its ability to maintain constant vigilance and surface opportunities for proactive intervention.

When precision targeting optimizes operations

Other environments benefit from more targeted alerting, for example:

Customer-facing areas

In retail or restaurant environments, precisely calibrated alerts maintain, preserve and improve the customer experience.

High-traffic zones

Areas with constant legitimate activity benefit from systems trained to distinguish between normal operations and genuine anomalies, for example loitering in a high-traffic forklift zone.

Operational efficiency priorities

When smooth workflows are paramount, precision alerting ensures that genuine safety concerns can be highlighted without disrupting routine operations.

The intelligence behind the alerts

The true power of modern computer vision lies in its ability to learn and adapt. Today’s AI systems continuously analyze patterns, movements, and behaviors to build an increasingly sophisticated understanding of unique operational environments.

This learning process means systems becomes more intelligent over time, naturally refining their ability to distinguish between routine activities and genuine safety concerns.

Continuous optimization: your competitive advantage

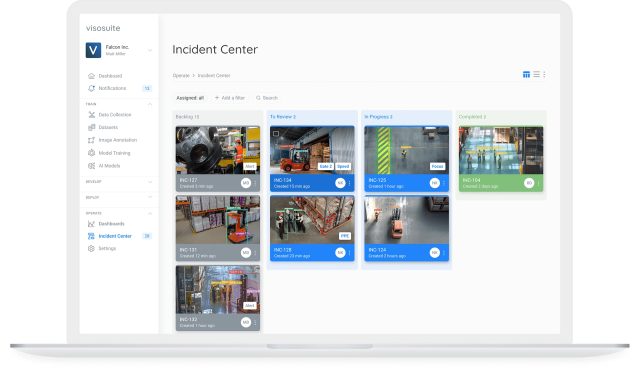

Your AI vision system isn’t static: it evolves with your business. Through ongoing calibration and feedback, you can:

- Adjust working patterns, styles and locations

- Refine safety alert thresholds based on emerging patterns

- Incorporate new safety protocols without hardware changes

- Scale monitoring capabilities as your operation grows

This adaptability ensures your safety monitoring evolves alongside your business priorities.

Finding your optimal balance

Consider these strategic questions:

- What level of incident coverage aligns with your safety priorities?

- How do you balance comprehensive monitoring with operational efficiency?

- Which areas of your operation would benefit most from intensive monitoring?

- Where might precision alerting better serve your goals?

Every organization will find their optimal point on the vigilance-precision spectrum. The key is having a system that gives you the flexibility to calibrate and recalibrate as needed.

The strategic value of comprehensive safety monitoring

Many organizations discover that implementing AI Vision reveals operational insights they didn’t know existed. The process of reviewing and responding to alerts often leads to improved processes, enhanced compliance, and stronger safety cultures.

Rather than viewing alerts as interruptions, leading organizations see them as intelligence: data points that inform better decision-making and drive continuous improvement.

Conclusion: precision engineering for safety excellence

AI Vision in safety monitoring isn’t about managing limitations: it’s about harnessing a powerful technology that can be precisely calibrated to match your strategic priorities.

Whether you choose comprehensive coverage or precision targeting, you’re deploying a system that adapts to your needs and grows with your operation.

The result? A safer, smarter, and more resilient operation powered by AI that’s engineered specifically for your success. Your safety monitoring system should work as hard as you do. With the right calibration, it will.