Ergonomic injury is a silent killer of manufacturing productivity.

Your best line supervisor calls in sick with back pain. Again.

Two more workers from the same shift are on restricted duty for wrist injuries.

You’re scrambling to cover shifts while managing workers’ compensation claims that will cost your company an average of $50,000 per incident.

Welcome to manufacturing’s most expensive hidden problem: ergonomic injury and musculo-skeletal disorders (MSDs).

By the numbers: manufacturing’s ergonomic injury crisis

MSDs cost US manufacturers over $13 billion annually – more than the GDP of many small countries. Unlike machine failures that trigger immediate alerts, ergonomic injuries develop invisibly, one repetitive motion at a time.

The statistics are staggering.

The human and financial cost:

- Manufacturing has an MSD incident rate of 41 per 10,000 workers – nearly double the private sector average

- 502,380 days away from work due to MSDs in 2021-22 alone

- Average workers’ compensation claim for an MSD: $50,000+

- Worker injuries cost employers more than $2,000 per employee annually

- Hidden costs (overtime, retraining, productivity loss): 4-5x the direct medical costs

The operational reality:

- 38% of all workplace injuries in manufacturing are MSDs

- Average time to return to work: 31 days for severe cases

- Repeat injury rate: 25-40% higher for workers with previous MSDs

These aren’t just statistics – they represent real bottom-line impact on your operations.

The traditional approach to ergonomic injury: too little, too late

Most manufacturing facilities rely on reactive ergonomic management: annual assessments that miss day-to-day variations, incident reporting after injuries occur, and periodic safety walks covering less than 5% of actual work performed.

This approach is like monitoring machine health by waiting for catastrophic failure.

By the time you see the problem, the damage is done.

Computer Vision: the ergonomic revolution

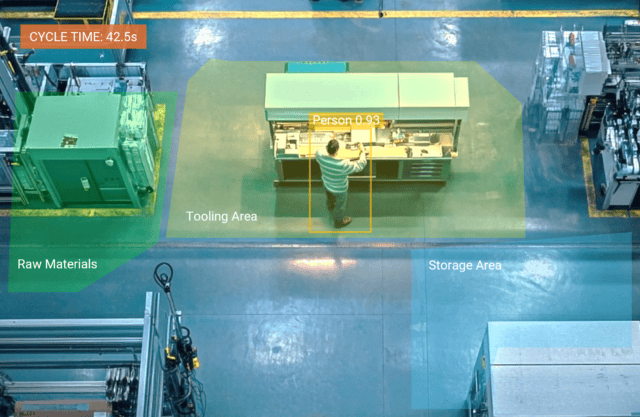

AI-powered computer vision transforms ergonomic monitoring from re-active to pro-active, providing continuous oversight that human observers cannot match.

Modern systems analyze live video feeds from existing cameras, using trained models to detect:

- Posture analysis: awkward bending, reaching, and twisting

- Repetitive motion patterns: high-frequency, high-risk movements

- Load handling: improper lifting techniques

- Prolonged static positions: extended periods in harmful postures

What makes AI Vision different:

- 100% coverage: every worker, every shift, every day

- Real-time alerts: immediate intervention before injury occurs

- Quantifiable data: metrics that prove ROI and guide investment decisions

Real-world impact: the business case in action

Case study: automotive parts manufacturer

A 500-employee automotive supplier implemented computer vision ergonomic monitoring across three production lines.

Before implementation:

- 23 MSD incidents requiring medical treatment

- $1.2 million in workers’ compensation costs

- 15% turnover rate attributed to injury concerns

After implementation:

- 6 MSD incidents (74% reduction)

- $310,000 in workers’ compensation costs (74% reduction)

- 8% turnover rate (47% reduction)

- 22% improvement in line efficiency

- ROI achieved in 14 months

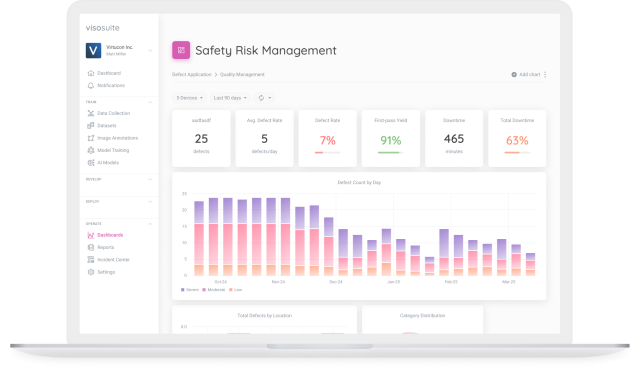

The leading indicators that change everything

Computer vision provides metrics that drive continuous improvement:

- Real-time ergonomic injury KPIs:

- Risk exposure time per worker/shift

- Repetitive strain frequency and intensity

- Intervention success rates

- Workstation comparative risk scores

This data transforms safety managers from compliance officers into strategic partners, providing executives with actionable intelligence that drives both safety and productivity improvements.

Addressing the executive questions

“How do we know this won’t disrupt production?”

Computer vision integrates with existing camera systems and requires zero changes to worker procedures. Implementation takes 48-72 hours per line with no production downtime.

“What about worker privacy and acceptance?”

Modern systems focus on posture and movement patterns, not individual identification. Workers often report feeling “looked after” rather than “watched.”

“Can we prove ROI before full deployment?”

The first step is starting with a pilot program on the highest-risk line. Within 90 days, there is quantifiable data on incident reduction, productivity improvements, and cost savings.

The hidden productivity multiplier

Beyond injury prevention, AI Vision delivers unexpected benefits:

- Quality improvements: preventing ergonomic strain reduces quality defects by 15-25% during high-demand periods.

- Efficiency gains: proper ergonomics reduces worker fatigue, increasing sustained performance with average productivity improvements of 12-18%.

- Retention benefits: companies with proactive ergonomic programs report 40% better retention rates, saving $15,000+ per prevented turnover.

- Insurance advantages: carriers offer premium discounts up to 35% for facilities with demonstrated proactive safety programs.

The competitive imperative

While you’re reading this, competitors may already be implementing computer vision ergonomic monitoring.

Early adopters of AI Vision gain advantages through:

- Lower operating costs from reduced injury expenses

- Higher productivity from less fatigued workforces

- Better talent attraction as safety-conscious workers prefer proactive employers

- Improved supplier relationships as customers require safety performance metrics

The $13 billion problem, solved

Manufacturing’s $13 billion ergonomic problem has a solution. Computer vision technology is proven, scalable, and delivering measurable results across the industry.

Every day you wait, preventable injuries occur in your facility.

Each month you delay, competitors gain advantages through pro-active safety programs.

Every quarter you postpone implementation, you’re leaving money on the table while putting workers at risk.

Computer vision ergonomic monitoring represents the future of manufacturing safety – where prevention replaces reaction, where data drives decisions, and where every worker goes home healthy.

The technology is available now, and the ROI is proven.

The only question is: will you lead the change or follow others who’ve already begun