The invisible risk: hidden hazards

In high-risk industries like manufacturing, construction, logistics, and utilities, hidden hazards are everywhere. Safety managers often ask: “Why do the same kinds of incidents keep happening, right under our noses?”.

The answer may lie not in what workers fail to see, but in what they see too often. When hidden hazards are seen every day, they become part of the scenery. This is familiarity bias in action: a well-documented tendency that leads us to ignore known risks simply because they’re no longer novel.

Take, for example, a cord repeatedly strung across a walkway, or a loading dock corner that’s tight on clearance. Operators might know it’s a risk. They might talk about it. But over time, it fades into the background, until an incident occurs.

That’s the blind spot challenge that hidden hazards presents.

The scale of the hidden hazard problem

The International Labour Organization (ILO) estimates over 374 million non-fatal work injuries occur globally every year. Many of these injuries happen not because new risks appear, but because old risks were ignored or normalized.

In traditional safety management, these risks often go unnoticed until an injury or audit exposes them. Why? Because:

- Manual inspections only capture short windows of activity.

- Shift changes create inconsistent supervision.

- Reporting systems rely on human awareness and willingness to speak up.

This is where AI Vision delivers a step-change.

What Is AI Vision?

AI Vision is the use of artificial intelligence to analyze live video feeds from CCTV or industrial camera systems. It doesn’t just record: it interprets. By applying computer vision models to common workplace scenarios, it can detect:

- Unsafe proximity between people and moving vehicles

- Unauthorized access to restricted zones

- PPE violations (e.g. missing helmets or gloves)

- Blocked exits or emergency equipment

- Unsafe ergonomic postures

And unlike people, it doesn’t get tired. It doesn’t miss details. It doesn’t blink.

Eliminating blind spots and detecting hidden hazards

AI Vision systems are designed to run on existing CCTV infrastructure, meaning there’s no need to install new cameras or halt operations. Within just a few days of deployment, a plant or facility can begin receiving live safety alerts and visibility dashboards.

Here’s what happens when you bring AI into your safety toolkit:

- Unseen risks become visible: familiar problems like blocked exits or common shortcuts are flagged the moment they occur

- Patterns emerge: AI identifies not just individual violations but repeat behaviors over time and location

- Hotspots are mapped: dashboards highlight areas with high-risk density, revealing environmental design issues or supervision gaps

This continuous visibility shifts the safety posture from re-active to pro-active.

Results you can measure

Companies using AI Vision consistently report improvements across several metrics. According to aggregated case studies:

- 40–60% reduction in incident frequency within the first year

- 25% increase in proactive interventions by EHS teams

- Up to 50% reduction in near-miss events, once they become visible and actionable

And critically, these results don’t just protect people: they protect operations:

- Fewer injuries mean fewer delays

- Better compliance means smoother audits

- Richer data means smarter decisions

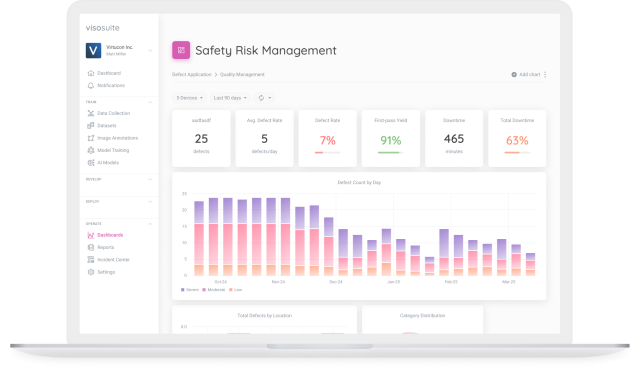

Real-time dashboards for real-time interventions

One of the most powerful features of AI Vision platforms is their ability to convert video data into live operational dashboards. These dashboards provide:

- Event logs categorized by severity and location

- Heatmaps of activity and risk zones

- Trend lines for comparing risk profiles week over week

- Clip libraries for safety briefings and root-cause analysis

This turns safety into a dynamic, data-driven function, rather than a static checklist exercise.

From alert to action: changing safety culture

One of the most surprising outcomes from AI Vision adoption is cultural.

When employees see that safety alerts are consistent, fair, and not personalized or punitive, they trust the system. And when leaders share short clips during toolbox talks to highlight how small moments can prevent serious outcomes, workers begin to think differently about everyday risks.

AI doesn’t replace people. It empowers them. It acts as a digital co-pilot for health and safety professionals, supervisors, and frontline workers alike.

Quick to deploy, simple to scale

Unlike large capital investments, AI Vision systems are:

- Quick to deploy (onboard in just a few days)

- Infrastructure-free (runs on current cameras)

- Scalable (manage multiple sites from a central dashboard)

This makes them ideal for multi-site manufacturing, waste management fleets, large-scale logistics, and distributed construction environments.

Final thought: seeing is preventing

Hazards don’t need to be new to be dangerous. In fact, it’s the familiar risks – the ones we walk past every day – that most urgently require our attention.

With AI Vision, we now have a way to overcome our blind spots. Not just by looking harder, but by seeing smarter.