For Health, Safety, and Environment (HSE) managers in complex industrial operations, the role comes with a constant mental checklist and focus on incident prevention. The consequences of missing something can be severe.

Common concerns that keep HSE managers up at night include:

- “Will today be the day a preventable accident happens?”

- “Are our incident prevention and safety controls working, or just assumed to be?”

- “Do we have the data to prove compliance if regulators ask tomorrow?”

- “Can I spot hazards before my team gets hurt, rather than after the event?”

- “What am I not seeing right now that could cause a shutdown?”

These aren’t abstract worries: they’re rooted in hard data.

Globally, over 2.78 million workers die each year from work-related accidents or diseases (ILO), and 374 million suffer non-fatal injuries.

In the US alone, workplace injuries cost $167 billion annually (NSC), with indirect costs – from lost productivity to damaged reputation – further multiplying the impact.

Why incident prevention is the priority

Among all safety measures, incident prevention and risk mitigation stand at the top because they:

- Directly prevent injuries and fatalities before they occur

- Avoid costly shutdowns and operational disruption

- Deliver immediate ROI through reduced claims, fines, and downtime

The stakes are high: the average cost of a workplace injury claim is $41,757 (NSC), while a fatality can exceed $1.4 million in direct costs.

This is without even counting reputational costs and operational damage. In high-risk industries, a single serious accident can jeopardize contracts, investor confidence, and even licensing.

Four applications of AI Vision for incident prevention

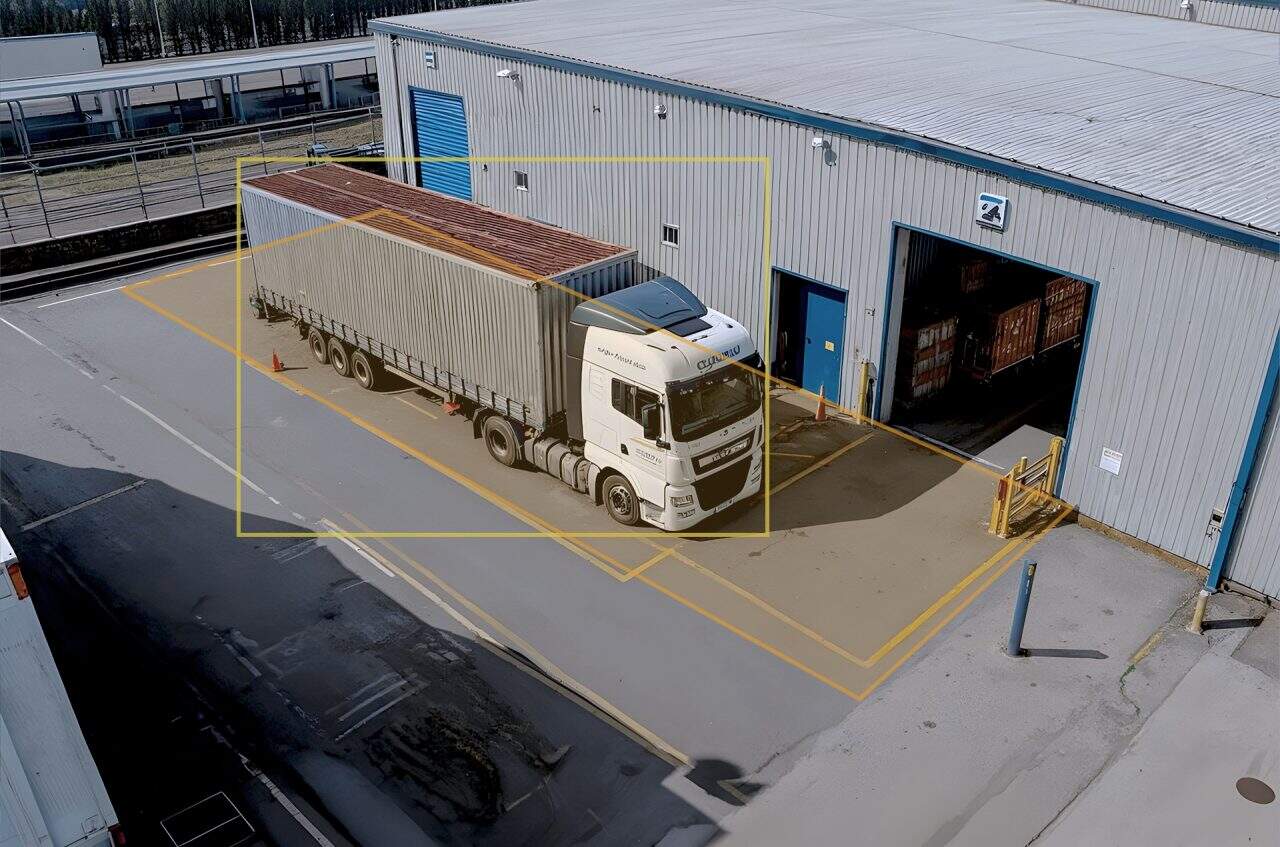

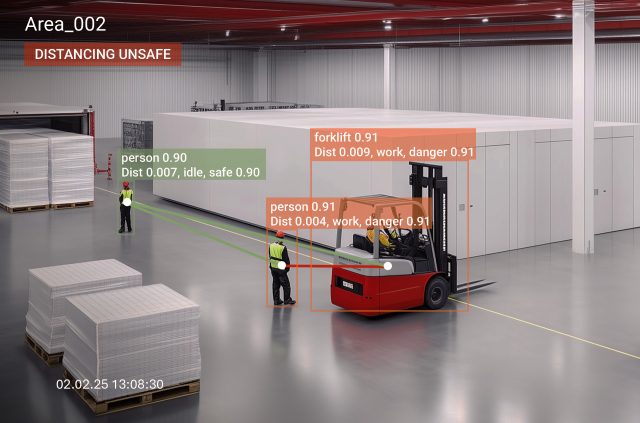

1. Forklift and vehicle movement monitoring

Key statistics:

Industrial vehicles cause over 11% of workplace fatalities and thousands of injuries annually. And forklift accidents alone cause 85 fatalities and 34,900 serious injuries every year (OSHA).

Key HSE concerns:

- Are drivers operating within safe speed limits?

- Are pedestrians staying out of vehicle zones?

- How do we manage blind spots in busy areas?

AI Vision enables:

- Automatic speed and route compliance checks

- Real-time alerts when pedestrians enter danger zones

- Blind-spot and intersection monitoring to prevent collisions

2. Slip, trip, and fall detection

Falls are the leading cause of lost workdays and one of the top three causes of workplace fatalities. Slips, trips, and falls result in over 244,000 serious workplace injuries annually in the US.

Key HSE concerns:

- Can we detect hazards before someone gets hurt?

- How fast can we respond if a fall happens?

- Are we tracking recurring risk areas?

AI Vision offers:

- Automated hazard spotting for spills, clutter, or uneven surfaces

- Instant alerts when a fall occurs for rapid medical response

- Heatmaps of hazard locations for targeted maintenance

3. Machine guarding compliance

Unguarded machinery is a direct path to catastrophic injuries. OSHA estimates $2 billion in annual costs from amputations and crush injuries linked to unguarded machinery.

Key HSE concerns:

- Are all safety guards and interlocks in place before operation?

- How do we catch unsafe bypasses in real time?

- Can we prove compliance during an audit?

AI Vision can:

- Verify guards are in place before the machinery starts

- Detect manual overrides or removed barriers

- Create a visual audit trail for regulatory proof

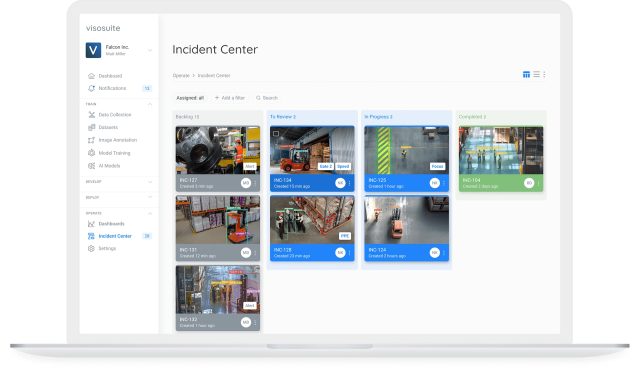

4. Near-miss detection

Near misses are often ignored, yet they are leading indicators of serious future incidents. Studies show for every serious injury, there are 29 minor injuries and 300 near misses (Heinrich’s Safety Pyramid).

Key HSE concerns:

- How many hazards are we missing simply because no injury occurred?

- Can we use near-miss data to redesign processes?

With AI-powered cameras:

- Unsafe proximity and interactions are automatically flagged

- Incident videos are logged for review and root cause analysis

- Patterns emerge for preventive action before real harm occurs

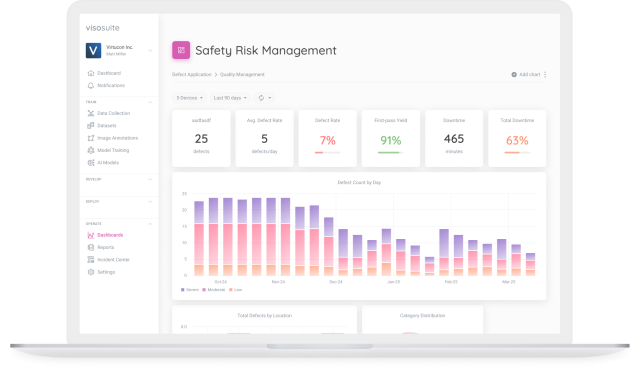

The ROI of incident prevention

Incident prevention isn’t just about safety – it’s about operational resilience.

Consider, for example, that:

- A single avoided forklift accident can save $188,000 in direct and indirect costs

- Reducing fall incidents by 25% can cut injury claims by tens of thousands per year

- Improving guarding compliance reduces downtime from machine lockouts or investigations

Shaping a safer, smarter future

For industrial HSE leaders, incident prevention is the most urgent and cost-effective safety investment available.

By deploying computer vision in these four key areas, managers can move from reactive to predictive safety: creating a workplace where hazards are addressed before harm occurs.

The payoff is measured not just in lives protected, but in uninterrupted productivity, regulatory confidence, and trust from both workers and stakeholders