Industrial vehicle safety consistently ranks as one of the top risks that keeps safety leaders up at night. Every year, over 34,000 serious injuries and 85 fatalities occur in the US alone due to forklift-related incidents.

In warehouses, manufacturing plants, and waste facilities, vehicle safety is essential. And the convergence of narrow lanes, blind spots, and pedestrian zones creates a high-risk environment – especially when the pace of operations accelerates.

For operations, EHS, and supply chain leaders, this isn’t just about compliance: it’s about protecting lives, minimizing disruptions, and keeping productivity moving without compromise.

The challenge: blind spots in vehicle safety

Forklifts are inherently risky due to their design: rear steering, limited sightlines, and heavy loads that obscure visibility. So most incidents happen not at high speed, but due to low-speed collisions, pedestrian impacts, or tipping from uneven surfaces.

Traditional vehicle safety solutions – mirrors, floor markings, audible alarms, driver training – are limited. They rely on human vigilance in overstimulating environments. Even CCTV systems offer only after-the-fact review. But the real risk lies in the gap between detection and response – a matter of seconds that legacy tools can’t close.

The AI Vision solution: seeing vehicle safety in real time

AI Vision is transforming vehicle safety from reactive to proactive. Using smart cameras and edge computing, AI-powered systems continuously monitor vehicle zones, detect risky behavior, and trigger real-time interventions, without needing human observation.

Unlike static CCTV, AI Vision systems “understand” their environment and can:

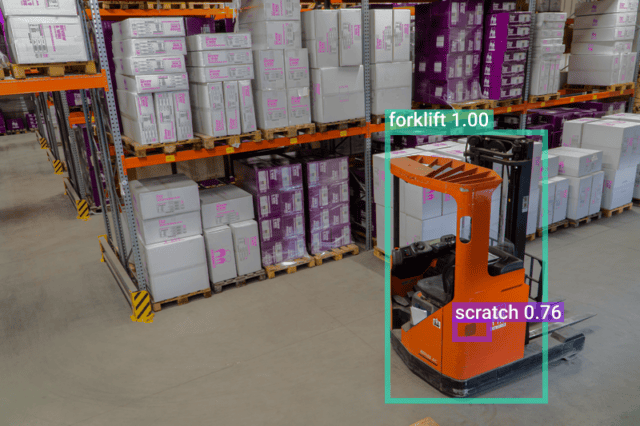

- Distinguish forklifts from pedestrians, shelves, or carts

- Detect unsafe proximity between workers and moving vehicles

- Recognize speeding, unauthorized operation, or route violations

- Trigger instant alerts – audio, visual, or mobile – before impact occurs

This is safety at the speed of vision: an always-on, scalable safeguard that supports human awareness, rather than replacing it.

Quick wins: three real-world use cases

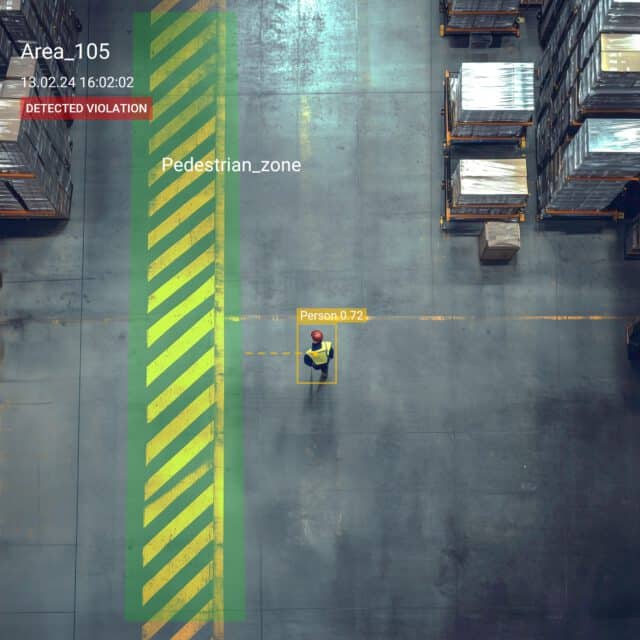

1. Pedestrian proximity alerting in shared zones

AI Vision systems detect when pedestrians enter forklift operating areas and automatically alert both the operator and the pedestrian. And this reduces the chances of overlooked co-workers in tight corridors or around blind corners.

Why it matters: Preventing just one collision can eliminate millions in legal, operational, and reputational damage.

2. Unsafe operation detection (speeding, route deviation)

Cameras positioned along defined routes analyze forklift movement patterns, flagging deviations or unsafe speed thresholds. So these insights can trigger alerts and contribute to ongoing driver behavior coaching.

Why it matters: Behavioral incidents often precede accidents. Early intervention drives safer habits.

3. Obstruction and load stability monitoring

AI Vision systems can detect when pallets or goods obstruct the operator’s line of sight or if a load appears unstable. And this helps flag tipping hazards before they result in injury.

Why it matters: Many injuries stem not from driver error, but from load-related incidents that were visually predictable.

Business impact and ROI

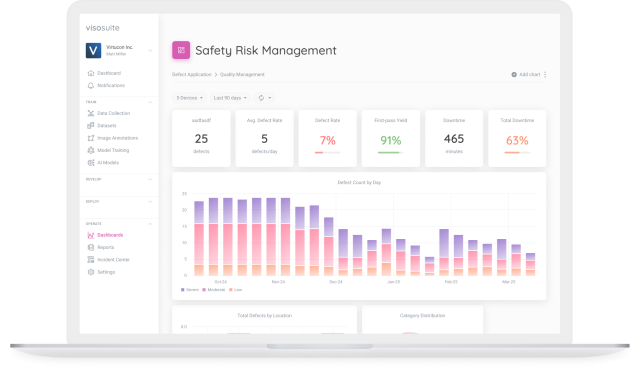

Organizations deploying AI Vision for vehicle safety report dramatic improvements:

- Up to 70% reduction in near-miss incidents involving forklifts

- Fewer downtime hours, thanks to lower accident-related investigations and disruptions

- Insurance premium reductions through improved safety KPIs and risk documentation

- Greater workforce trust and morale by visibly investing in employee safety

These outcomes directly support safety KPIs, OSHA reporting accuracy, and ultimately, operational uptime.

Why traditional vehicle safety isn’t enough

Manual enforcement of vehicle safety depends on human consistency: something even the best safety cultures struggle to maintain at scale. Spot checks miss moment-to-moment dangers. Mirror-only awareness doesn’t account for human blind spots, distractions, or noise interference.

AI Vision brings precision, consistency, and immediacy to environments where seconds can save lives.

This isn’t about replacing workers or watchdogs: it’s about giving them superpowers.

Addressing privacy and workforce adoption

One common concern: “Are we just adding surveillance?”

The answer lies in the architecture: edge-based processing ensures video data doesn’t leave the site. Only anonymized detections and safety alerts are stored. No facial ID. No behavior scoring. Just real-time risk awareness.

When workers see AI Vision as a guardian, not a guard, trust improves. Many unionized sites now see AI Vision as a critical part of their collaborative safety strategy.