Safety ROI and the data dilemma

Safety leaders know this moment well: you’re in the management meeting, advocating for better PPE enforcement, more field audits, or an investment in safety systems.

You explain the risks. You cite the potential direct and indirect costs of failure. And then comes the question: “What is the return on investment (ROI) of safety?”

The truth is, occupational safety and health has always been a difficult sell in business terms. It’s easy to quantify the cost of a new AI system. Now it’s also easier to calculate safety ROI with a new methodology powered by AI Vision, compared to previous, more reactive and manual monitoring.

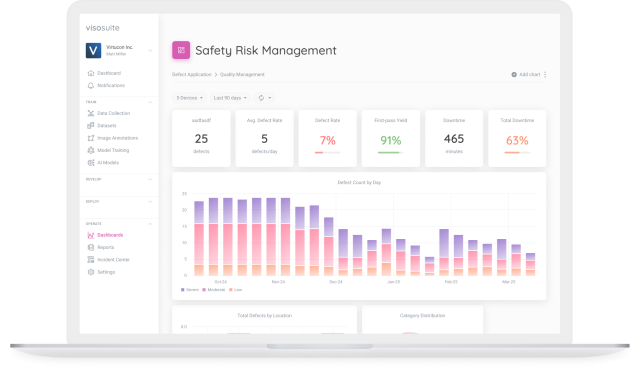

Visual intelligence – driven by real-time video analytics – is giving health and safety and operations leaders the tools they’ve long needed: quantifiable KPIs that demonstrate safety ROI, showing how safety programs improve productivity, reduce risk exposure, and protect the bottom line.

Why traditional safety metrics fall short

Most organizations rely on lagging indicators – data collected after an event occurs:

- Lost time injury (LTI) rates

- Recordable incidents

- Audit findings

- Reported near-misses

While important, these metrics don’t show risk: they show consequences. They also fail to capture the full scope of risky behaviors that don’t result in incidents but could have.

In other words, you’re only measuring what you can see. And what you can see is often just the tip of the iceberg.

AI Vision: turning visibility into KPIs and safety ROI

AI Vision systems analyze live video from existing CCTV or IP camera networks using trained computer vision models. These models detect a range of behaviors and conditions relevant to workplace safety, such as:

- Missing or improper PPE usage

- Unauthorized access to hazardous areas

- Vehicle-human proximity violations

- Unsafe body positions during lifting or machine use

- Environmental hazards like blocked fire exits

But beyond detection, these systems also track, quantify, and visualize this data across time, shifts, and sites.

Leading indicators that matter

With AI Vision, safety teams gain access to real-time leading indicators, such as:

- PPE compliance rates (per shift, zone, or individual)

- Near-miss frequency (categorized by risk severity)

- Safety zone violations (e.g. pedestrian/vehicle overlap)

- Repeat infractions (by behavior or area)

- Behavior heatmaps (risk frequency by location)

This allows teams to predict and prevent incidents, not just respond to them. According to aggregated deployment data, companies using AI Vision saw:

- 50% improvement in safety-related KPIs within 90 days

- 30–40% reduction in serious safety violations within 6 months

- Increased pro-active hazard reporting with video used for training

The business case for safety ROI

These KPIs also translate directly into operational and financial outcomes:

- Lower injury rates = reduced insurance premiums and claims

- Improved uptime = fewer disruptions, less overtime required

- Better compliance = smoother audits, fewer penalties

- Workforce retention = fewer incidents, better morale

And unlike traditional safety reports that arrive monthly or quarterly, AI Vision dashboards update in real time, keeping managers informed and accountable daily.

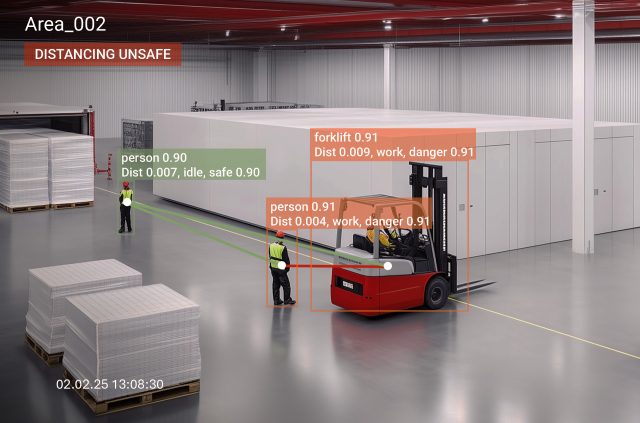

A real-world scenario: logistics center

Consider a logistics center where workers regularly navigate forklifts and foot traffic in shared zones. The company had no major incidents, but a rising number of “near-miss” anecdotes from workers.

By deploying AI Vision:

- The team discovered that 17 unsafe interactions per day were going unreported

- They mapped out specific intersections where risks peaked during shift transitions

- Intervention with signage and behavior coaching led to a 60% reduction in violations in 3 weeks

Armed with these stats and supporting video, the health and safety lead secured executive approval to replicate the intervention company-wide, proving both safety ROI and leadership value.

Safety leaders as strategic partners

In today’s operations-driven organizations, the health and safety team is no longer seen as a compliance function – it’s increasingly becoming a strategic enabler.

When safety managers walk into C-suite meetings, they can gain influence, shape budgets, and make safety a business advantage with:

- Measurable performance improvements

- Trend graphs showing risk reduction

- Cost avoidance models tied to KPIs, and

- Real-time visibility into high-risk zones

Deployment that doesn’t disrupt

One reason AI Vision adoption is growing fast is that it doesn’t require complex new systems. It’s built to integrate:

- With existing cameras – working with an edge device

- Into current health and safety workflows – with digital safety tools

- Across multiple sites – from one central dashboard

- In under 48 hours – zero downtime to activate

That makes it a scalable, low-friction investment with high upside – and one that not only speaks the C-suite’s language, but can save lives.

Tying safety to productivity

Every safety incident or rule-break is a form of process variation. AI Vision reduces both physical risk and operational entropy, aligning directly with Lean Six Sigma’s goal of minimizing defects and maximizing flow.

One of the hidden strengths of AI Vision is its dual value: while originally deployed to improve safety, it often reveals operational inefficiencies too, especially through lost productivity.

1. Ergonomic risk = efficiency drag

Improper lifting doesn’t just risk musculoskeletal injuries: it slows task cycle times and increases fatigue-related errors. AI Vision detects posture and lifting strain in real time, reducing injury risk and optimizing movement efficiency for repeat tasks like pallet loading or parts handling.

2. Obstructed pathways = process bottlenecks

Cluttered walkways and blocked emergency exits are visual symptoms of upstream process inefficiencies, like poor staging or material replenishment delays. AI Vision flags obstructions dynamically, enabling root-cause analysis of layout or sequencing issues that cost both safety margin and throughput.

3. Near-miss vehicle events = logistics inefficiency

Every near-miss between forklifts and pedestrians isn’t just a safety risk: it reflects inefficient routing, visibility constraints, or floor layout flaws. AI Vision builds heatmaps of traffic conflict zones, helping teams reroute flows to reduce dwell times and improve delivery precision inside facilities.

4. PPE non-compliance = downtime risk

Workers missing PPE like gloves or goggles may trigger audits or pauses, but more often, they signal deeper behavioral or training gaps. AI Vision identifies non-compliance patterns by shift, line, or task, not just to reduce injury risk, but to pre-empt compliance-triggered delays and rework in regulated industries.

5. Unsafe behavior = reliability risk

Unsafe ladder use or shortcut-taking often correlates with rushed work or staffing mismatches. AI Vision doesn’t just enforce protocols. It reveals where pressure on throughput is driving unsafe behavior, letting managers address root causes with better job pacing or staffing coverage.

When safety KPIs improve, so does productivity. And when both move together, ROI becomes undeniable.

Final thought: from cost center to value driver

Prioritizing safety culture doesn’t have to be a sunk cost. With AI Vision, it becomes a source of measurable performance improvement, a catalyst for cultural engagement, and a proof point for long-term operational excellence.

Real-time KPIs aren’t just numbers. They’re a bridge between safety and strategy.

When you can show the value of prevention in dollars saved, minutes gained, and lives protected from injuries and illnesses, you don’t have to sell safety anymore. You lead with safety ROI and make a meaningful impact for your team, C-Suite, and organization as a whole.