Saving lives in the workplace is the ultimate challenge, especially in technical, complex industrial environments. For teams in some of the most high-risk industries – manufacturing, construction, energy, logistics – every day on the job carries real danger.

The devastation and human impact of workplace fatalities are beyond tragic. The impact on families, friends and co-workers is unimaginable. For businesses they can also be financially and reputationally devastating.

On average, a single workplace death can cost an organization $1.2 million in direct and indirect costs, including workers’ compensation, legal fees, insurance premiums, productivity loss, and brand damage. And most importantly, many of these deaths are entirely preventable.

Despite the best intentions of health and safety teams – PPE rules, compliance signage, training seminars, safety checklists, and rigid standard operating procedures (SOPs) – human error still slips through.

Workers become fatigued, distracted, or overconfident. Hazards go unnoticed in dynamic environments. Safety violations go unreported. Supervisors simply cannot be everywhere.

AI-powered computer vision offers a new path: one that fills the critical monitoring gaps left by traditional methods and brings safety enforcement into real-time, continuous operation.

AI that doesn’t blink: a new approach to safety

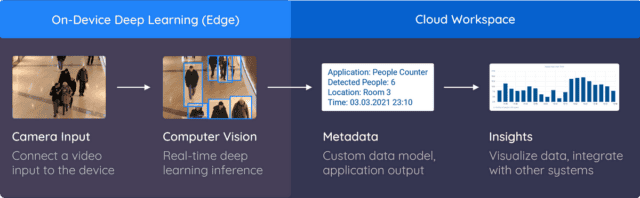

What can be more important than saving lives, especially when there are simple solutions today powered by AI? Computer vision, powered by AI, uses cameras and edge computing to monitor environments in real-time. It doesn’t sleep, doesn’t blink, and doesn’t lose focus.

Smart systems understand what they see: detecting anomalies, identifying risky behaviors, and triggering instant alerts.

This technology is not about surveillance. It’s about building resilient, proactive safety ecosystems. Instead of reacting to accidents after they happen, AI Vision gives organizations the tools to anticipate, prevent, and mitigate dangers before they escalate.

For health and safety executives, this represents a paradigm shift: from documentation to detection, from reporting to real-time response, from compliance-focused to culture-focused.

What keeps health and safety leaders up at night?

Health and safety executives face a set of escalating challenges:

- High incident rates despite compliance efforts

- Labor shortages, leading to under-supervised sites

- Regulatory complexity, especially across multiple jurisdictions

- Pressure to demonstrate safety KPIs and reduce compensation claims

- Difficulty achieving safety culture maturity across contractor-heavy operations

Most safety programs rely on a patchwork of paper reports, retrospective audits, and spot inspections. These provide historical context, but lack predictive insight. They identify root causes, but crucially only after an injury or fatality occurs.

AI Vision doesn’t replace traditional safety roles: it amplifies them. It provides a digital set of always-on eyes, backed by intelligent models, to fill the blind spots.

Three ways AI Vision saves lives

1. Fatigue detection and worker alerting

AI systems can now detect signs of fatigue through posture tracking and behavioral cues like prolonged stillness or erratic motion. When the system identifies fatigue indicators – reduced reaction times or stumbling – it sends an automatic alert to both the worker and supervisor.

Why it matters: Fatigue-related accidents are a top contributor to workplace fatalities, especially during night shifts or in repetitive high-load roles. Catching drowsiness early prevents cascading failures.

2. Unsafe behavior pattern recognition

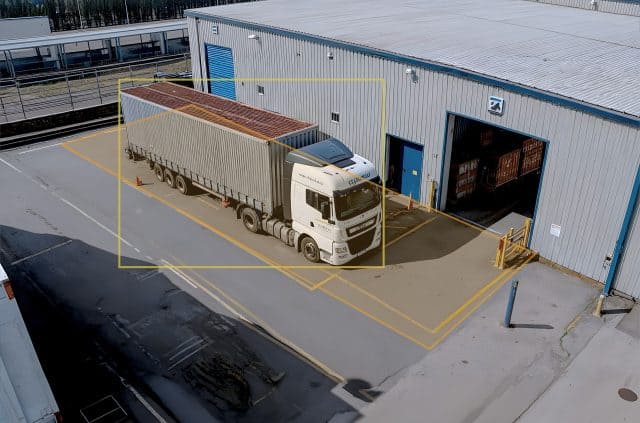

AI Vision learns how a safe work environment should look, and recognizes when workers bypass machine guards, enter restricted areas, or handle tools improperly. Instead of reviewing hours of footage after an incident, anomalies are flagged instantly.

Why it matters: Unsafe behavior is a leading indicator of future incidents. Traditional inspections often miss these moments in real-time. AI Vision catches deviations as they happen and can automatically log them for training.

3. Predictive accident prevention

By combining real-time video analytics with historical incident data, AI Vision platforms can predict the likelihood of future accidents. For example, it may identify a location where near-misses have increased due to equipment congestion or poor lighting and prompt a mitigation response.

Why it matters: Predictive tools allow safety teams to focus resources where they’re needed most, before someone gets hurt.

Real results: the ROI of saving lives

The business case for computer vision in safety is no longer speculative. It’s data-backed and boardroom-ready:

- 90%+ reduction in workplace fatalities in AI-monitored zones

- 500% increase in near-miss detection and reporting accuracy

- $50,000+ saved per prevented incident, not including long-term brand and workforce stability benefits

Beyond cost savings, AI Vision helps organizations build trust with insurers, regulators, and the workforce.

Insurance providers often offer premium discounts to companies demonstrating proactive risk mitigation. OSHA inspections tend to be more favorable when automated, time-stamped records are available.

Why traditional safety isn’t enough

Health and safety teams face an impossible task: monitoring hundreds or thousands of people, spread across complex worksites, with limited staffing. Paper-based audits or reactive investigations can’t scale with the speed of real-world hazards.

Human vigilance alone isn’t sufficient. It needs support and augmentation.

AI Vision doesn’t replace people: it supports them. It reduces information overload, standardizes detection quality, and provides actionable insight in the moment, not weeks later.

Privacy-respecting safety: doing it right

One of the biggest concerns around AI Vision is worker privacy. That’s why modern solutions are built around edge-based processing, where video is analyzed locally. Only metadata – such as alerts or incident types – is stored. The best platforms ensure that any and all data remains with the end user, not the solution provider.

No identity-based tracking. Nor the need for constant recording of individuals. And no specific profiling of workers.

These systems focus on behavioral safety, not surveillance. And when workers understand that AI is used for protection, not punishment, adoption improves. The result is a safer, more collaborative environment, not a controlled one.

What’s next: safer sites, smarter decisions, scalable solutions

As AI models grow more advanced, so do the possibilities:

- Complex multi-step hazard recognition (e.g., spill plus electrical risk)

- Integration with wearables and environmental sensors for real-time context

- Cross-site benchmarking to identify systemic issues in large enterprises

- Contractor safety tracking in real time, even without permanent IDs

Vision-based safety isn’t just a trend: it’s a foundation for the next generation of data-informed, zero-harm operations.

Final word: don’t wait for a tragedy

Every incident prevented is a life saved, a family spared, and a future protected.

The question isn’t whether you can afford to implement AI Vision. It’s whether you can afford not to. With tools now readily available, waiting for an incident to justify investment is a dangerous gamble.

Safety leaders have a responsibility, an obligation, and an opportunity: to act now, before it’s too late.