In high-risk environments like manufacturing, logistics, and construction, PPE monitoring is essential. Even 1% non-compliance in PPE (Personal Protective Equipment) can mean the difference between safety and catastrophe.

According to the U.S. Bureau of Labor Statistics, as many as 60% of workers injured on the job were not wearing the required PPE. So clearly, PPE monitoring is a huge challenge, especially 24/7, across dynamic sites.

But it’s not just about helmets and vests: it’s about maintaining a culture of consistent protection, even in the face of fatigue, rushing, or oversight. And manual audits can’t catch what AI Vision sees in real time.

The challenge: invisibility of everyday risk

Traditional PPE monitoring and enforcement methods rely on:

- Periodic audits and compliance logs

- Supervisory spot-checks

- Manual reporting after incidents

But workers remove helmets temporarily. High-vis vests go unnoticed on the night shift. In fast-paced operations, violations are frequent, fleeting, and often unseen.

This leaves companies exposed:

- Legal liability and insurance risks

- Undermined safety culture

- Inconsistent enforcement across shifts or sites

So what’s needed isn’t more paperwork: it’s proactive, always-on PPE monitoring and awareness.

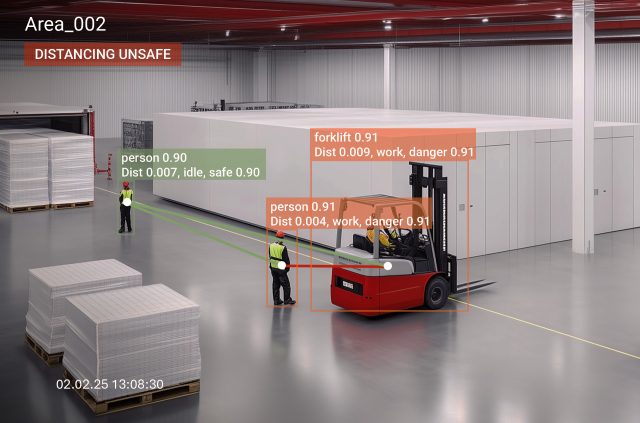

The AI Vision solution: real-time compliance at scale

AI Vision transforms PPE monitoring and enforcement from episodic to continuous. Through edge-deployed smart cameras, systems recognize whether required PPE is present and alert when it’s not.

So here’s how it works:

- AI models are trained to detect helmets, vests, goggles, gloves, and more.

- Detections are site-specific, configured for zone rules (e.g., goggles in chemical areas).

- Alerts are triggered instantly – via lights, buzzers, or mobile devices.

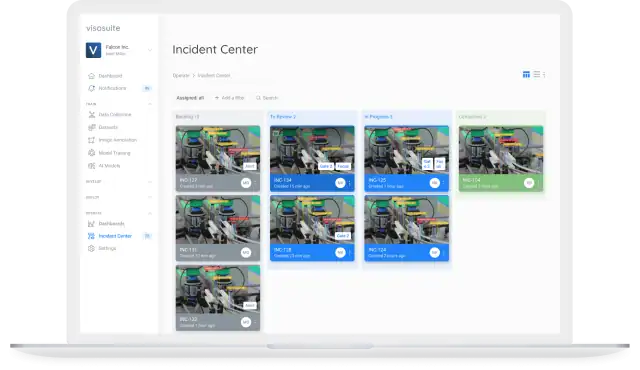

- Data is logged automatically for reporting and compliance audits.

This enables consistent enforcement without human policing and shifts safety from a rule to a reflex.

Quick wins: three use cases driving results

1. Helmet detection at entry gates

AI Vision verifies that all personnel entering a hazardous zone are wearing helmets. Missing PPE triggers audio alerts and can even delay gate access.

Why it matters: 27% of head injuries in industrial settings happen within 10 minutes of site entry.

2. Vest visibility in low-light or outdoor environments

AI models analyze contrast levels and material reflectivity to detect whether high-vis gear is being worn, even in poor lighting or at night.

Why it matters: Manual checks often fail when lighting conditions shift. AI Vision doesn’t blink.

3. Custom PPE zone rules (e.g., gloves in fabrication, masks in paint bays)

AI Vision allows enforcement of site-specific requirements by zone or task. If gloves are required in a fabrication cell, entering without them triggers a localized alert.

Why it matters: It’s not just what you wear, it’s where you wear it.

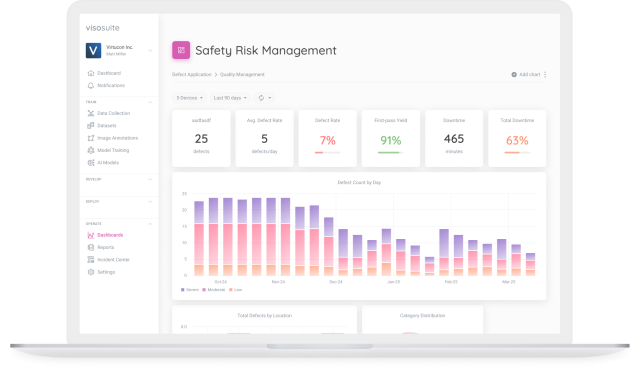

Business impact and ROI

AI Vision for PPE has delivered measurable gains across industries:

- 98–99% compliance rates sustained over time

- Fewer injuries and OSHA citations from non-compliance

- Faster new hire onboarding through visual reinforcement

- Automated audit trails reduce paperwork and investigator time

Some sites reported a 30% reduction in injury-related downtime within the first quarter of deployment.

Why traditional safety isn’t enough

Manual PPE enforcement creates gaps and fatigue. Supervisors can’t be everywhere. Peer enforcement causes tension. And non-compliance often becomes normalized when no one is watching.

AI Vision solves for:

- Consistency: every zone, every shift, every worker.

- Timeliness: alerts in seconds, not days.

- Documentation: every event logged and report-ready.

Legacy systems audit the past. AI Vision protects the present.

Addressing privacy and workforce concerns

Workers fear surveillance, but that’s not what AI Vision does.

These systems run on edge devices, meaning no video leaves the site. Detections are anonymized, focused only on PPE presence, not identity. The goal is not to punish, but to prevent.

In unionized environments, co-designed alert thresholds and zone rules have increased trust. When workers see the tech prevents injury – not monitors behavior – they become allies in its success.

What’s next: smart wearables and predictive safety

AI Vision is just the start. Integrations are emerging that link:

- Wearables and RFID tags for PPE validation

- Predictive models to flag at-risk zones based on historical non-compliance

- Digital twin environments to simulate PPE risk across facility layouts

PPE monitoring and compliance is no longer a checklist: it’s a living, intelligent system.

Final word: failure isn’t an option

You can’t afford PPE failure: not when the cost is measured in injuries, insurance, and trust.

With AI Vision, companies are achieving 99%+ compliance, unlocking a smarter, more protective environment where safety is worn, seen, and enforced at all times.