Managing workplace safety risks in industrial work environments

Every day, facilities and sites navigate a high-stakes balancing act: maximizing throughput while managing a host of workplace safety risks in order to swiftly unlock improvements.

From high-speed vehicles and moving machinery, to lone workers and volatile materials, for industrial safety teams, the mandate is clear but increasingly difficult:

- Maintain compliance

- Enforce safety rules, and

- Prevent incidents

Crucially, all of this must be balanced and achieved in fast-moving, dynamic settings.

Yet traditional workplace safety tools – manual inspections, routine audits, and retrospective reporting – are struggling to keep pace. Risks often appear between checks, near misses go unrecorded, and worker behavior naturally shifts when being observed.

In this reality, industrial safety oversight needs augmentation: not replacement, but reinforcement. This is where AI Vision, the use of computer vision for real-time safety monitoring, is reshaping how industrial safety is managed and measured.

Workplace safety: from risk management to real-time intervention

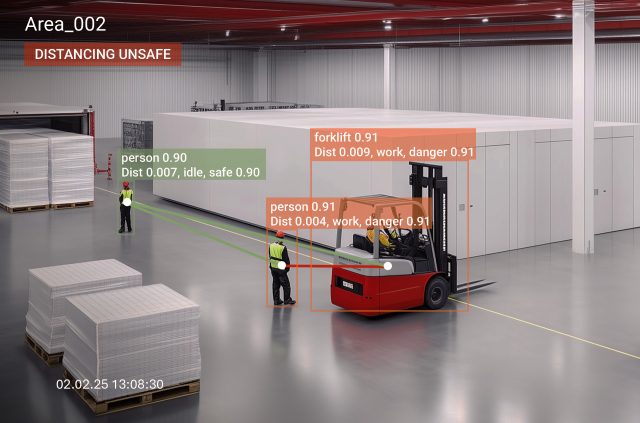

AI Vision turns standard video cameras into intelligent workplace safety monitors that analyze activity 24/7. With ‘eyes that never blink’, cameras flag unsafe acts as they occur, triggering instant alerts for faster intervention.

Whether it’s a forklift veering into a pedestrian zone, a missing PPE item at an entry gate, or a lone worker in a restricted area, AI Vision captures what people often miss.

This shift from passive surveillance to real-time detection helps organizations shrink the time between hazard and response, from potentially hours to just seconds.

Early adopters have reported:

- 55% reduction in PPE non-compliance

- 60% decrease in near-miss incidents

- 75% fewer restricted zone intrusions

- 50% drop in vehicle-related safety events

These gains are not just industrial safety metrics: they translate into fewer injuries, reduced downtime, avoided fines and an improvement in bottom line.

From surveillance to safety intelligence

AI Vision isn’t about more cameras or more footage: it’s about actionable data.

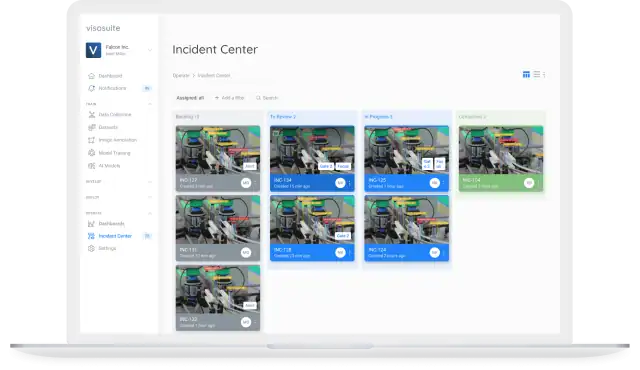

All detected workplace safety events are logged and categorized in centralized dashboards. This gives HSE leaders site-wide visibility at-a-glance, across multiple shifts and locations.

Rather than sorting through hours of CCTV, safety managers can instantly access trend data, asking and answering higher-value questions such as:

- Which zones see recurring violations?

- Which behaviors are increasing in frequency?

- What retraining is required?

With this level of granularity, leaders can:

- Pinpoint emerging risks before they lead to incidents

- Prioritize interventions based on real-time data

- Verify compliance with timestamped video evidence, and

- Inform continuous improvement with accurate, contextual insights

In an era of increasing regulatory scrutiny and third-party audits, this transparency also streamlines compliance (such as ISO 45001 (occupational health and safety) and ISO 9001 (risk management and continuous improvement)).

Verifiable video records accelerate audit readiness and support customer-facing safety certifications.

A practical path to safer workplace operations

Adopting AI Vision doesn’t require a full digital overhaul.

Most implementations begin by leveraging existing camera systems already in place. The technology layers on top of what organizations already use, making adoption low-friction and highly scalable.

A typical rollout path includes:

- Safety assessment: evaluate high-risk zones and define objectives

- Pilot deployment: apply models in key areas and validate impact

- System tuning: refine detection thresholds and train frontline teams

- Scale up: expand coverage site-wide and integrate with EHS systems

This modular, phased approach ensures minimal disruption while proving value early, allowing organizations to move from pilot to enterprise-level deployment in under three months.

Creating a culture of proactive workplace safety

Perhaps most importantly, AI Vision supports a shift in mindset: from reactive enforcement to pro-active prevention. It removes blind spots, builds trust in safety metrics, and empowers teams to act on facts rather than assumptions.

For industrial safety professionals, this means more time spent improving systems and less time buried in incident reviews. For executives, it means real confidence that safety isn’t just policy: it’s being enforced and lived in real time. And for workers, it means a tangible investment in their wellbeing that’s visible every day.

As regulatory demands grow and the cost of preventable incidents rises, AI Vision delivers on both compliance and culture: supporting not just better safety outcomes, but a safer way of working.

Final thought: safe workplaces enabled by ‘eyes that never blink’

In high-risk environments, what isn’t seen often causes the most harm. Traditional occupational safety practices, while essential, can’t catch everything, and that’s where AI Vision earns its place.

By providing uninterrupted visibility, instant alerts, and data-driven insight, AI Vision becomes the ‘eyes that never blink’, helping teams anticipate, respond and improve with precision.

It turns workplace safety from a tick-box exercise into a continuous practice, and supports a future where zero downtime and zero harm isn’t aspirational, rather it is operational.

For those leading safety in complex industries, this isn’t just about adopting new technology. It’s about gaining the capability to protect people, performance and productivity, for every minute, of every shift.