Value-driven AI. Trusted globally.

Our customers are rapidly developing advanced computer vision applications with Viso Suite. From global manufacturers to leading construction firms, viso is trusted by Fortune 500 companies and industry leaders worldwide.

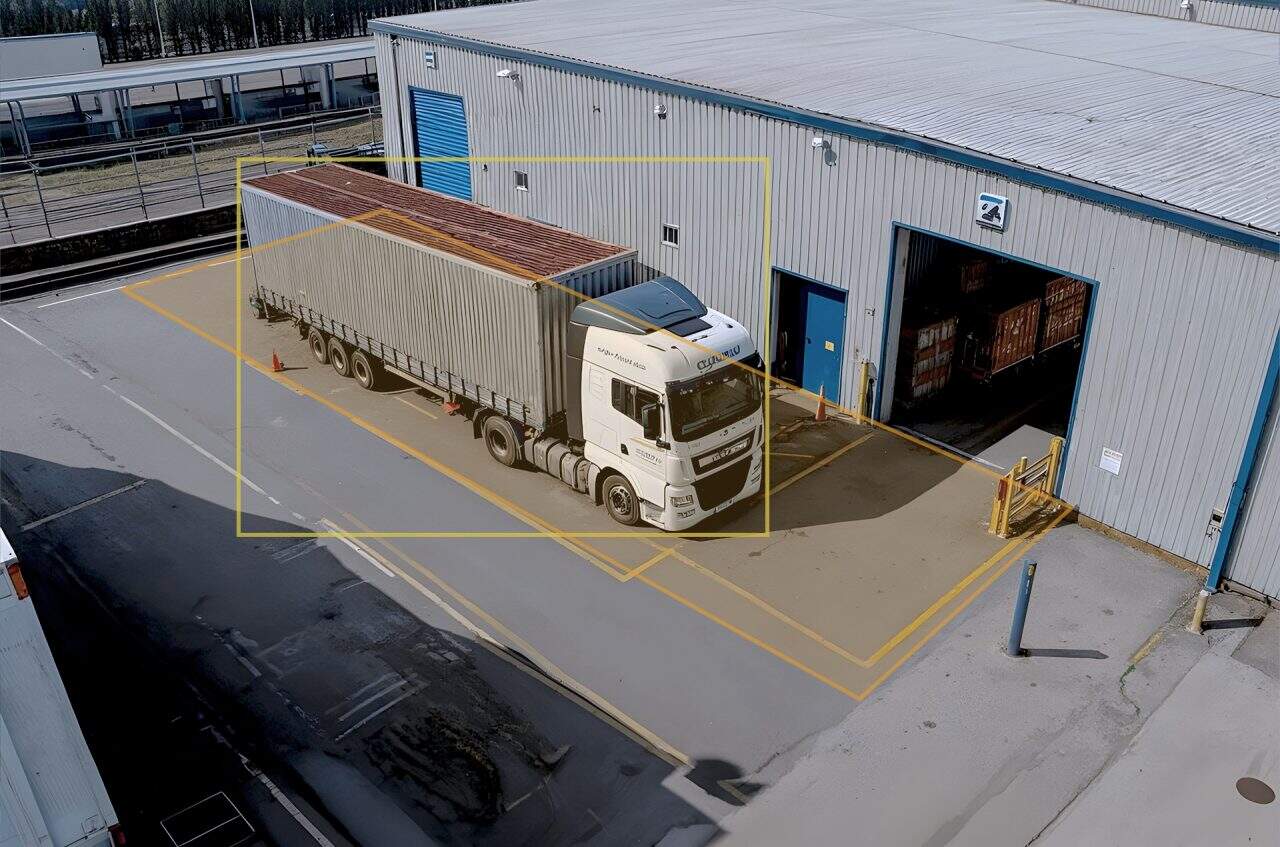

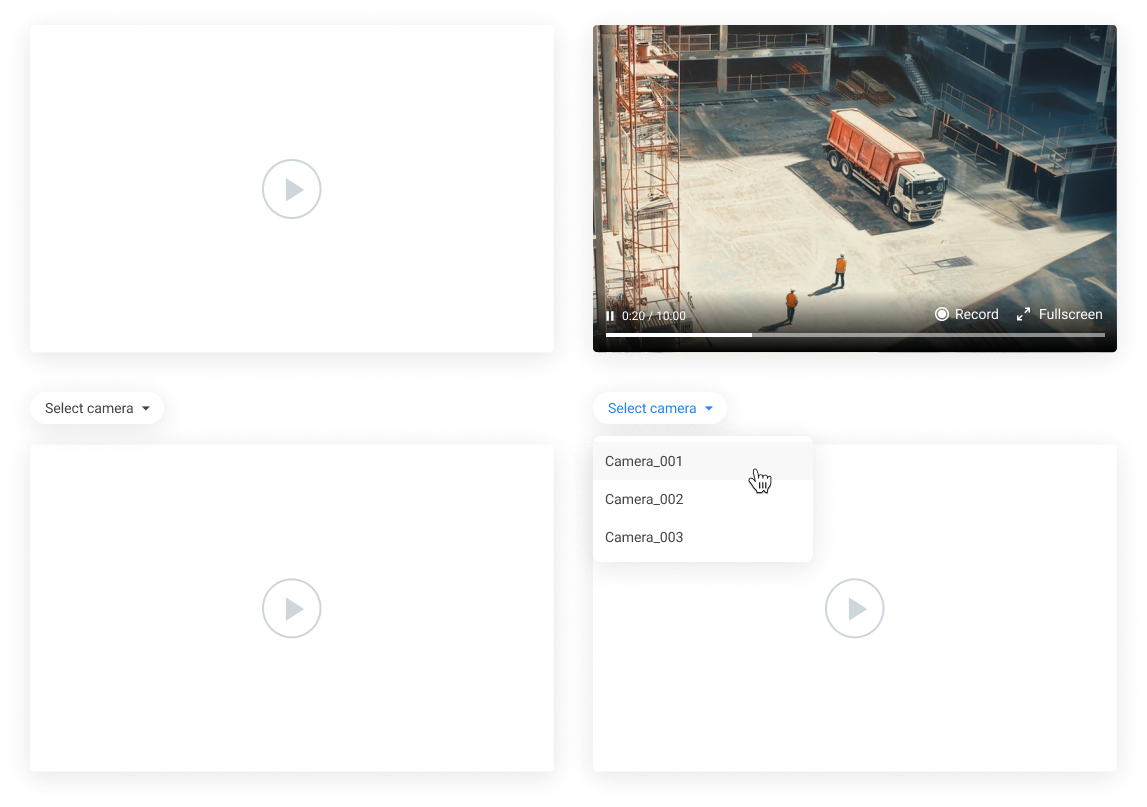

Get real-time visibility into your operations

Connect cameras across sites

Powered by the viso AI Platform, plug into your local network, connect your cameras, and process all your data on-site.

- Plug and play connectors

- Supports all modern cameras

- Scale to hundreds of cameras

- Secure on-prem processing

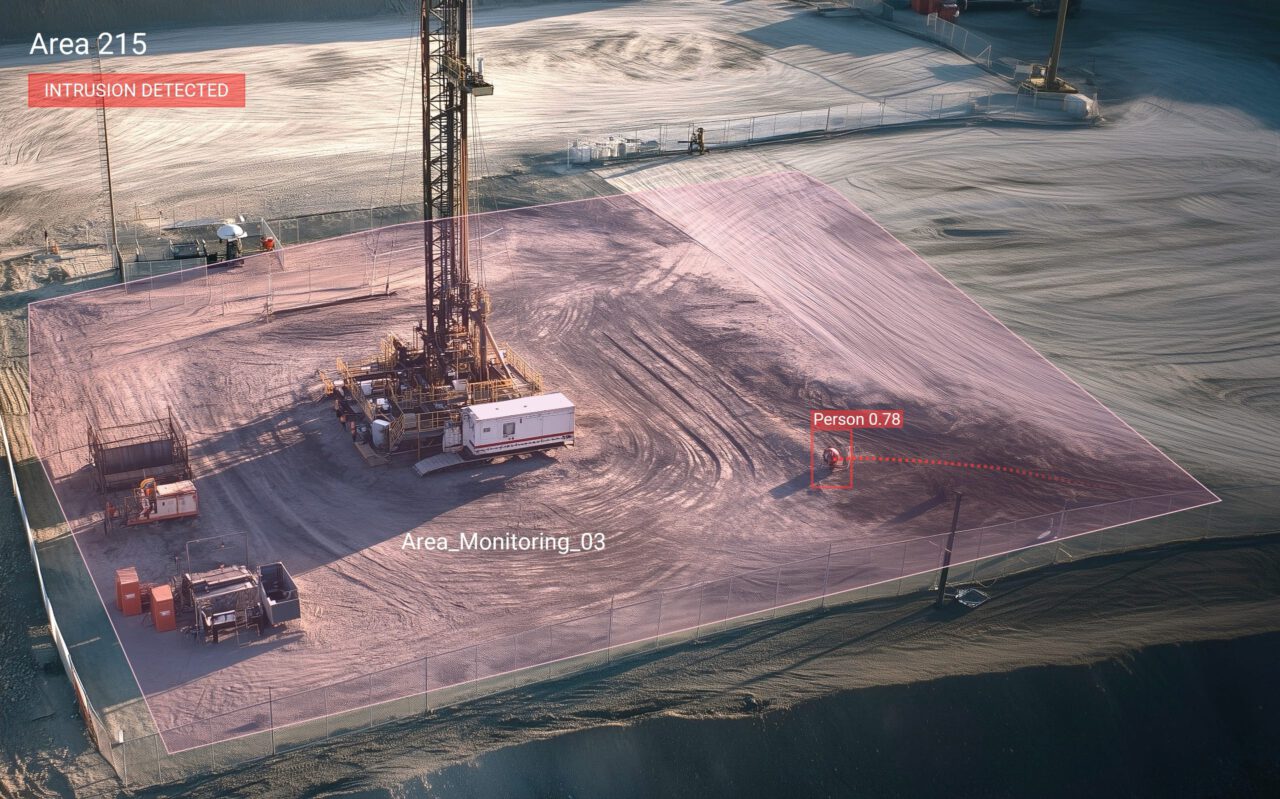

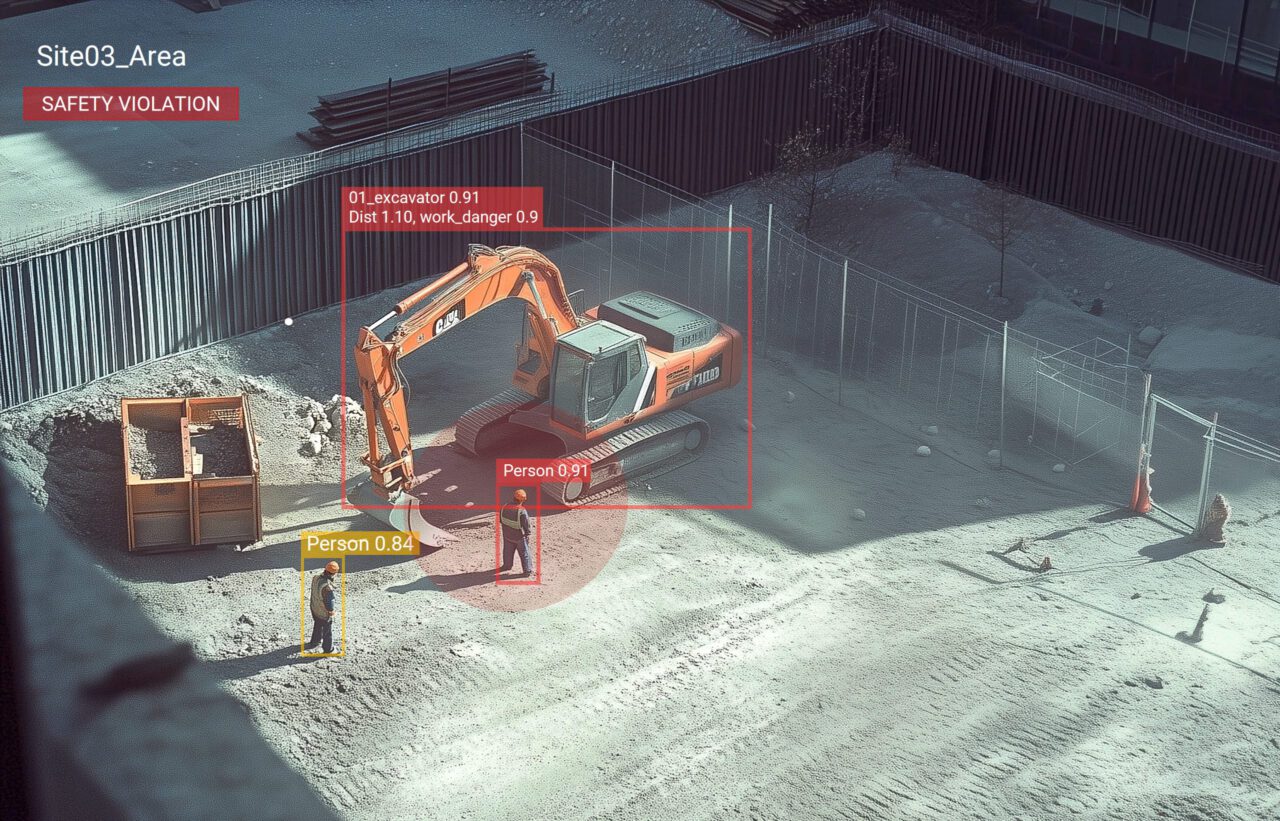

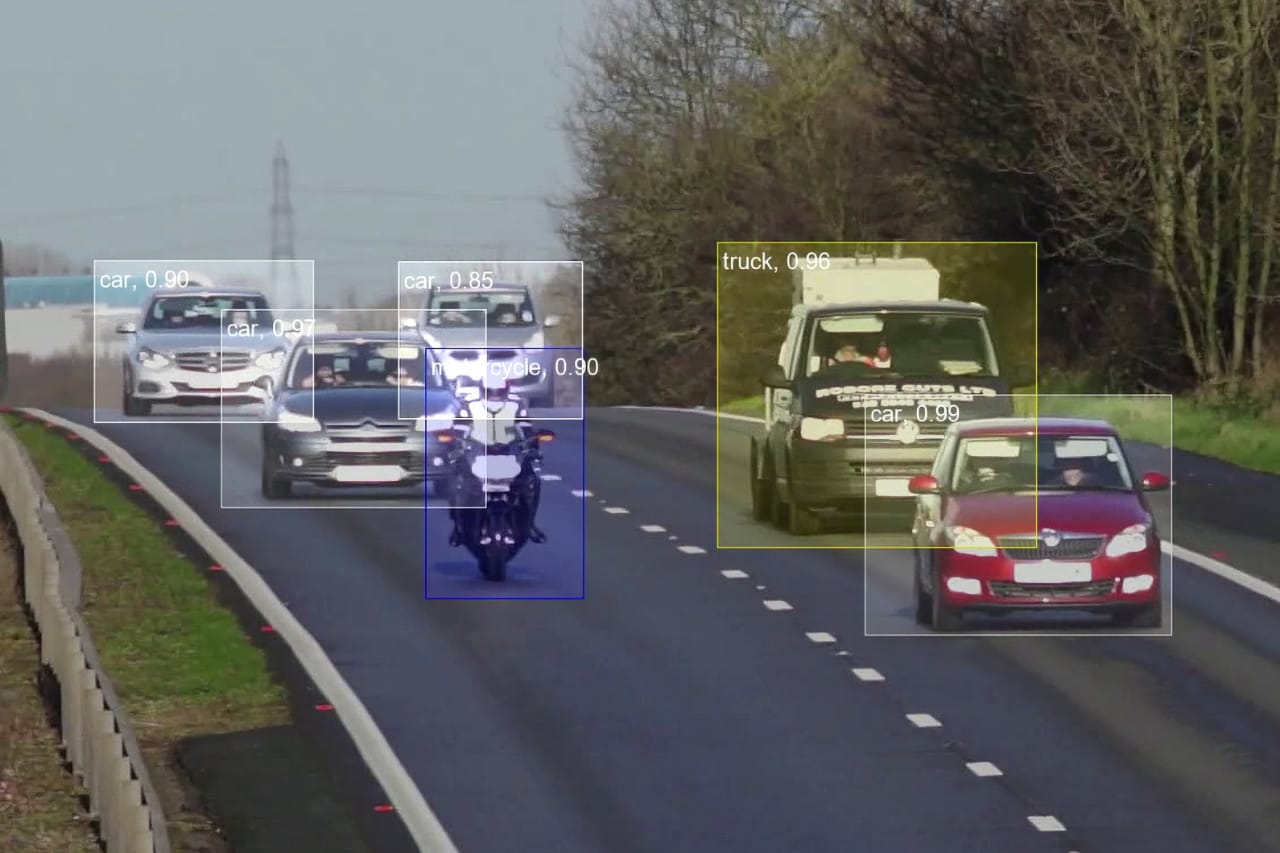

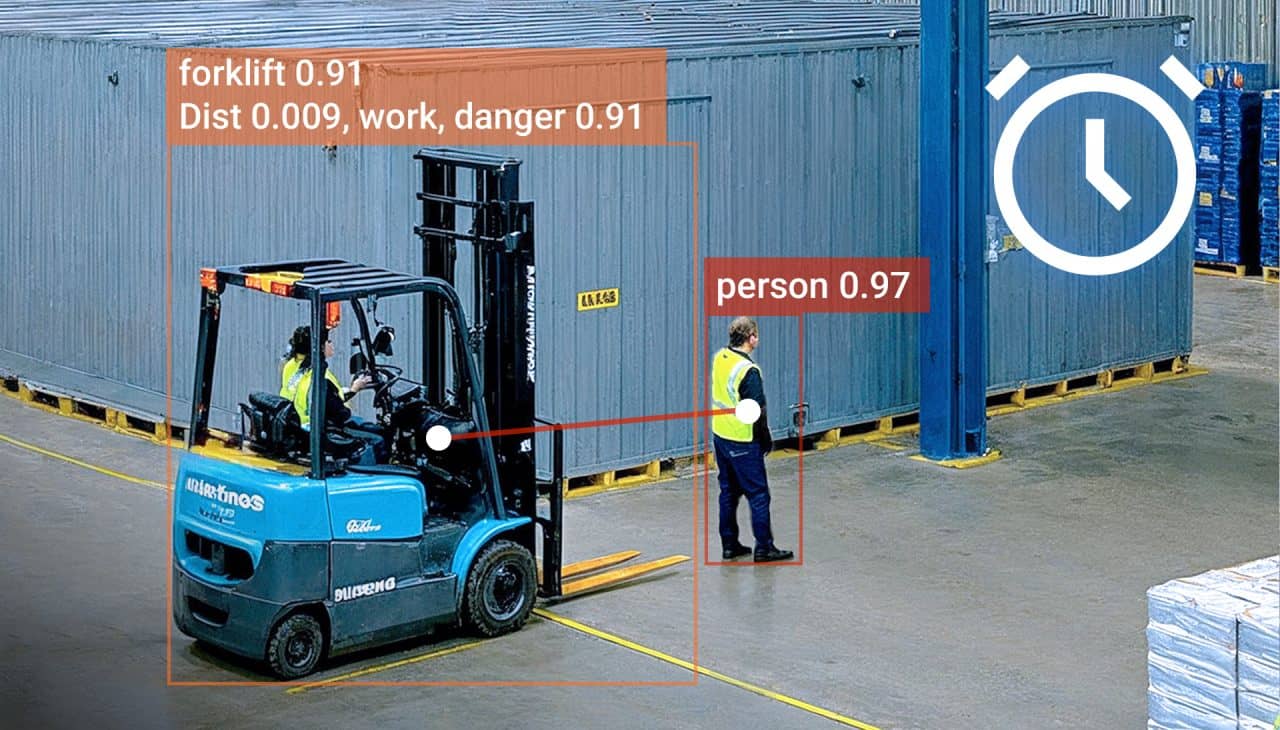

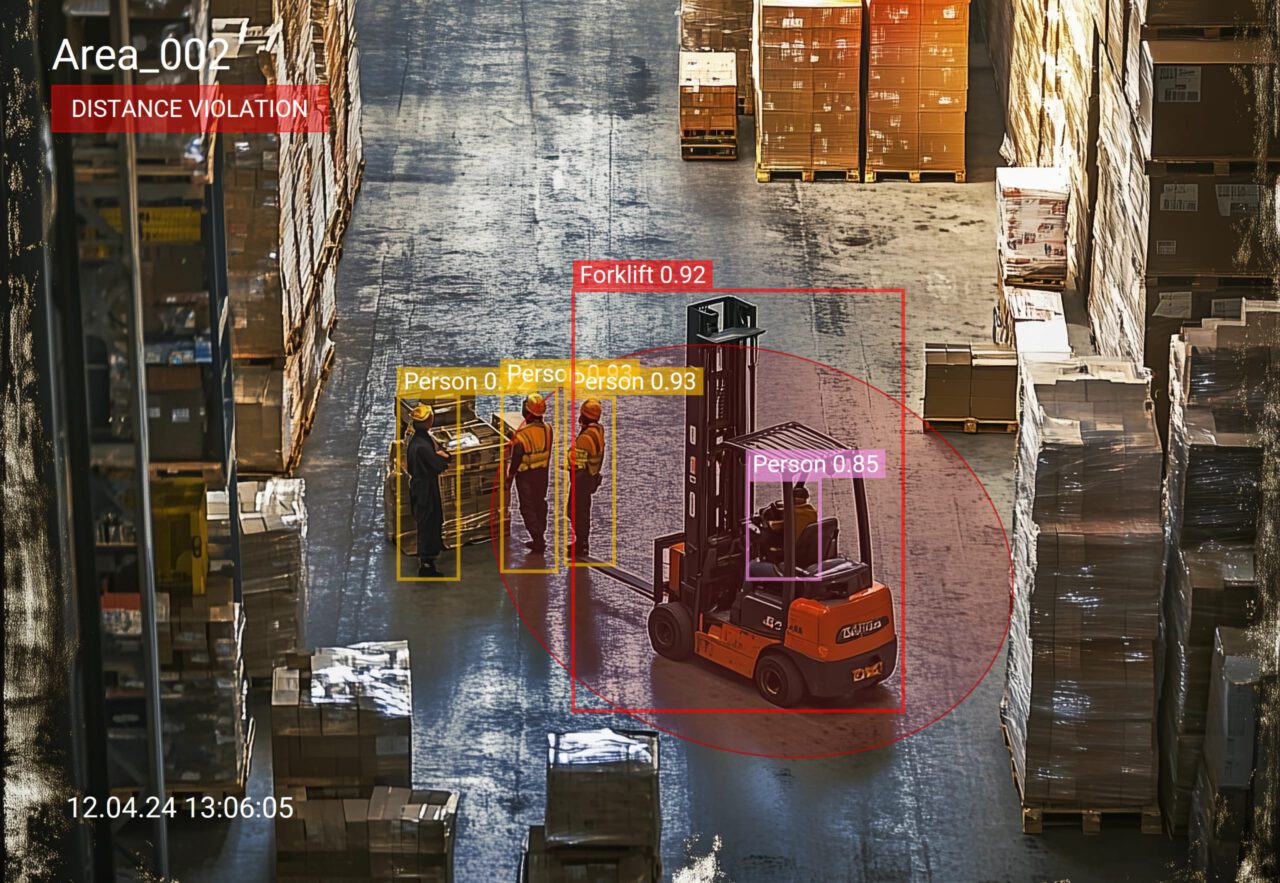

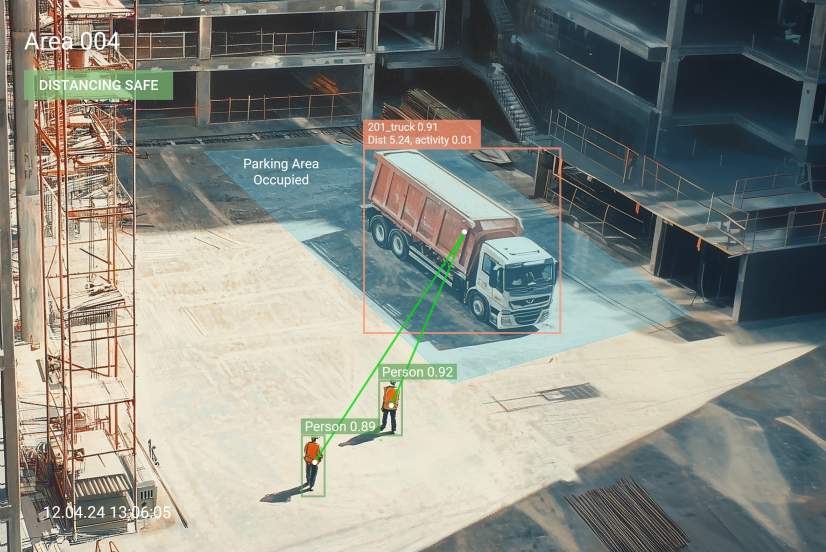

Detect risks in real-time with AI

Our AI platform leverages your domain knowledge, allowing you to teach your cameras how to understand risk and danger early.

- Train AI on auto-pilot

- Unmatched customization

- Flexible safety rules

- Full control over your data

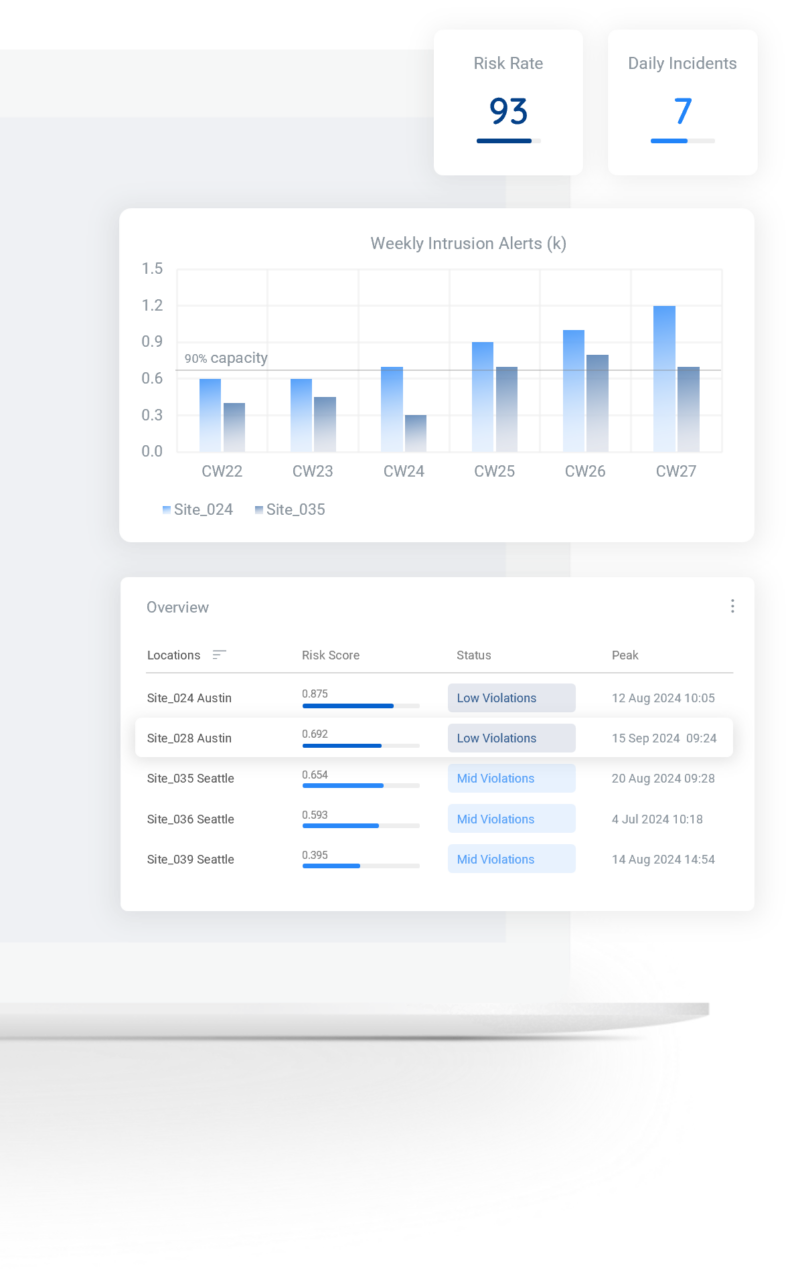

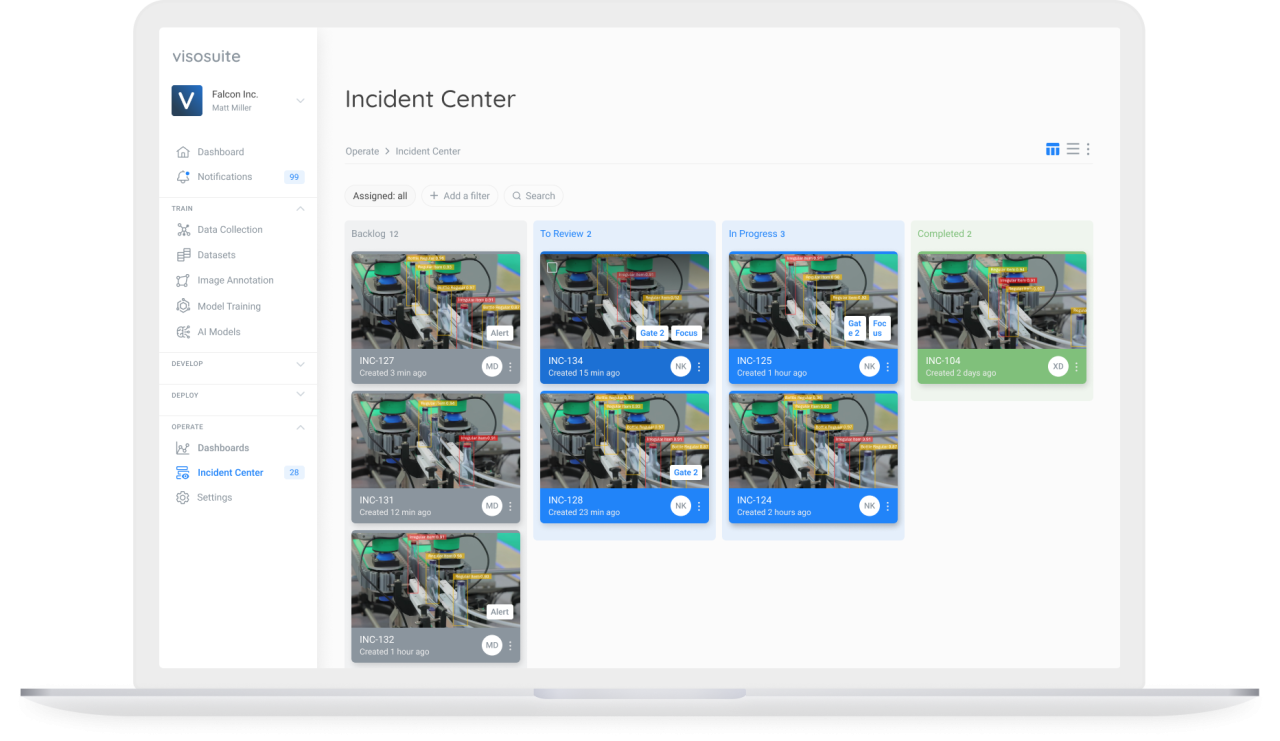

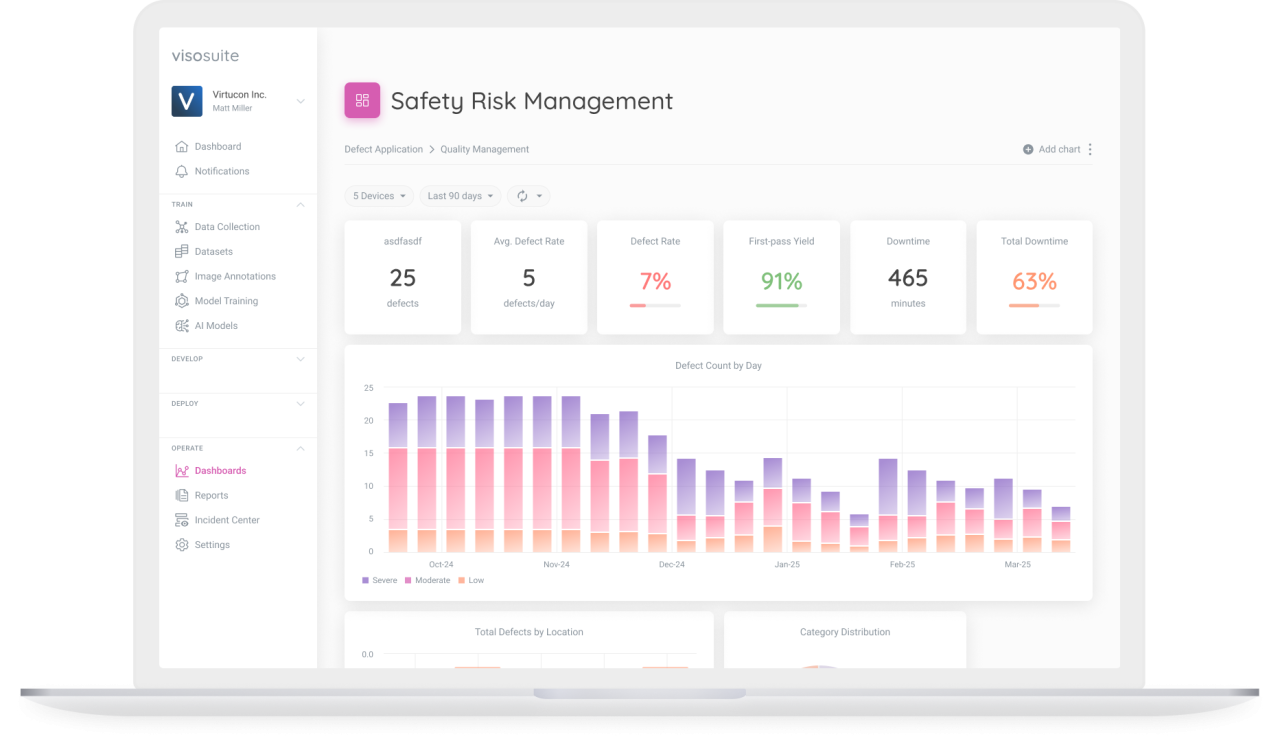

Make better decisions faster

Build safety reports and monitor risk scores to enhance the basis for making better decisions in health and safety meetings.

- Automated safety reporting

- Incident monitoring and alerting

- Custom live dashboard builder

- Real-time and trend analysis

Leading construction companies choose viso

The most popular computer vision applications in construction

Read articleProcess adherence and productivity

Keep tabs on critical workflows in real time and ensure tasks are carried out consistently and according to plan, helping you meet tight deadlines and maintain budget control.

Real time detection

Flag hazards and inefficiencies so you can take corrective action, prevent delays and enhance overall productivity.

Proven results in weeks, not years

Get results rapidy, with viso's end-to-end solution

Exec. briefing

Technology assessment

Production trial

Application deployment in production

2 hours

2 - 3 days

8 - 12 weeks

3 - 6 months

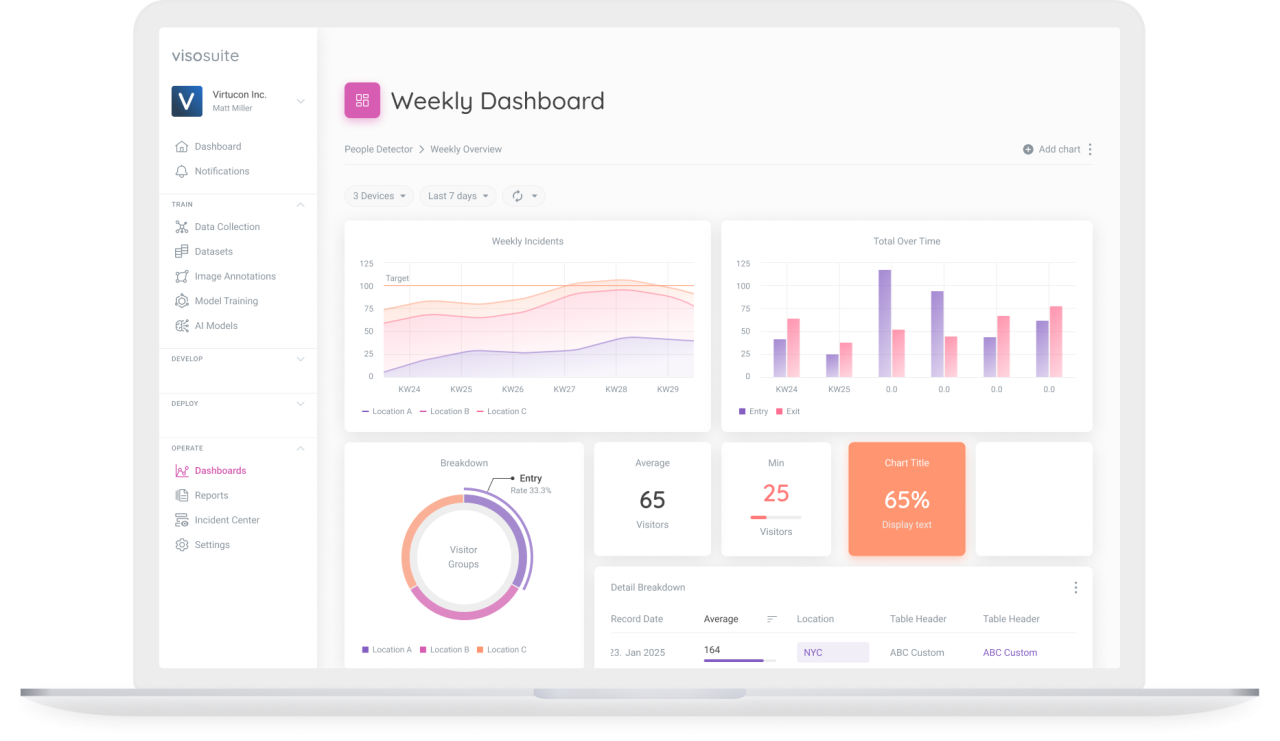

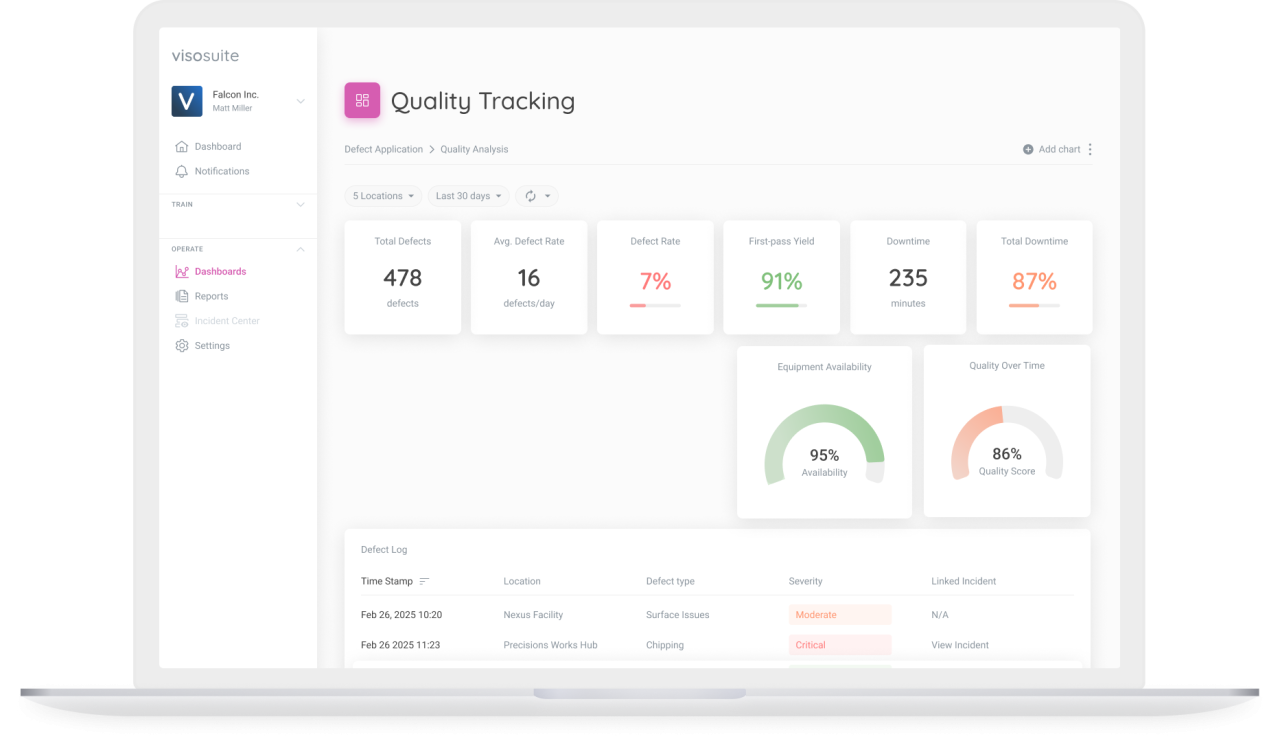

All-in-One solution to build and operate computer vision applications

Turn data into high-performance models

Collect, manage, and refine high-quality data to build accurate AI models tailored to your business needs.

Viso Suite

Develop and customize applications faster

Develop and customize computer vision applications with an intuitive, flexible platform designed for enterprise-scale solutions.

Viso Suite

Scale seamlessly across devices

Rapidly roll out applications across multiple locations, ensuring seamless integration with existing systems.

Viso Suite

Monitor, optimize, and evolve

Maintain peak performance with real-time monitoring, automated updates, and enterprise-grade security.

Viso Suite