Manufacturing

Lean and Efficiency Suite

Maximize efficiency. Minimize waste. Deliver continuous improvement.

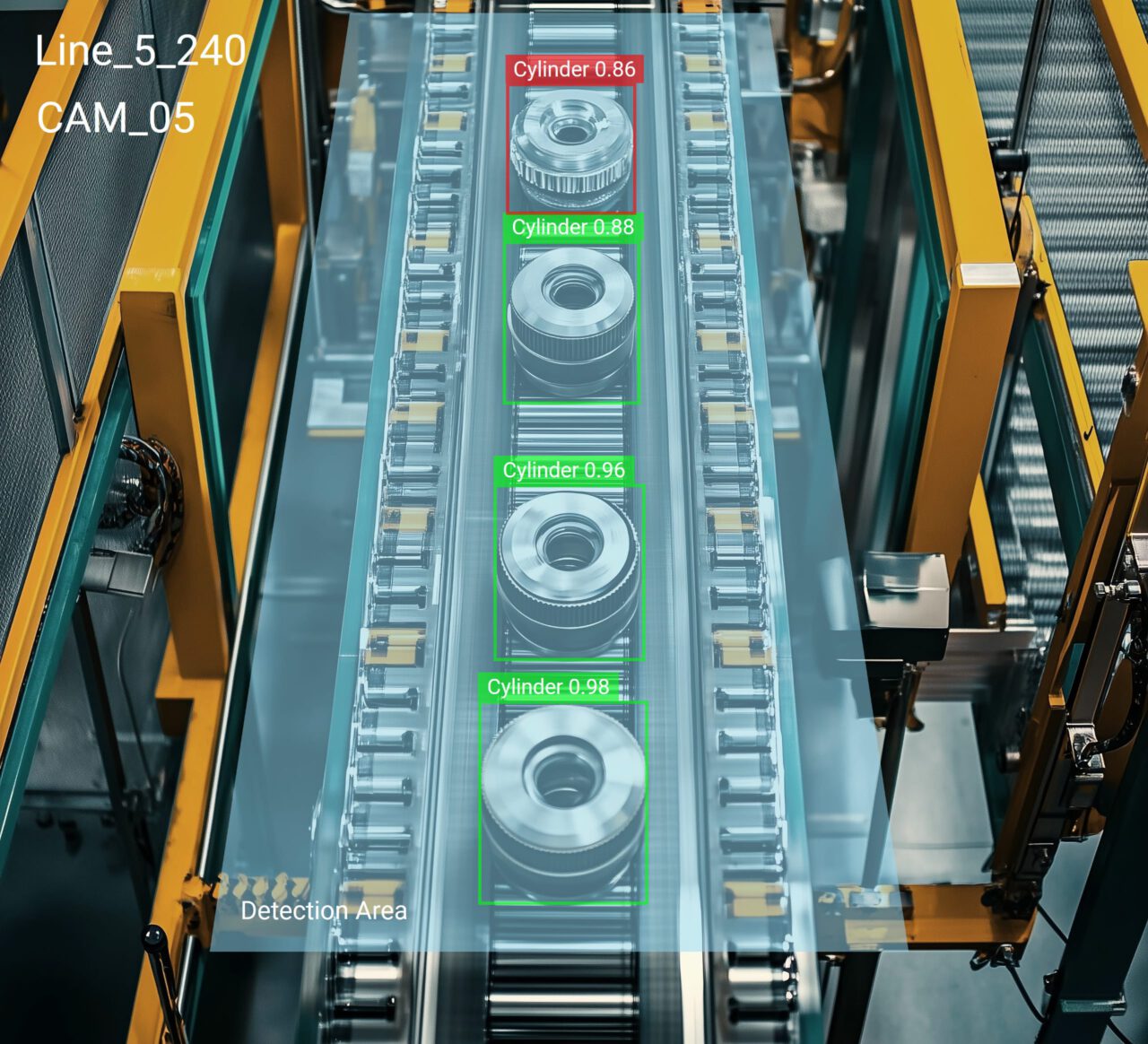

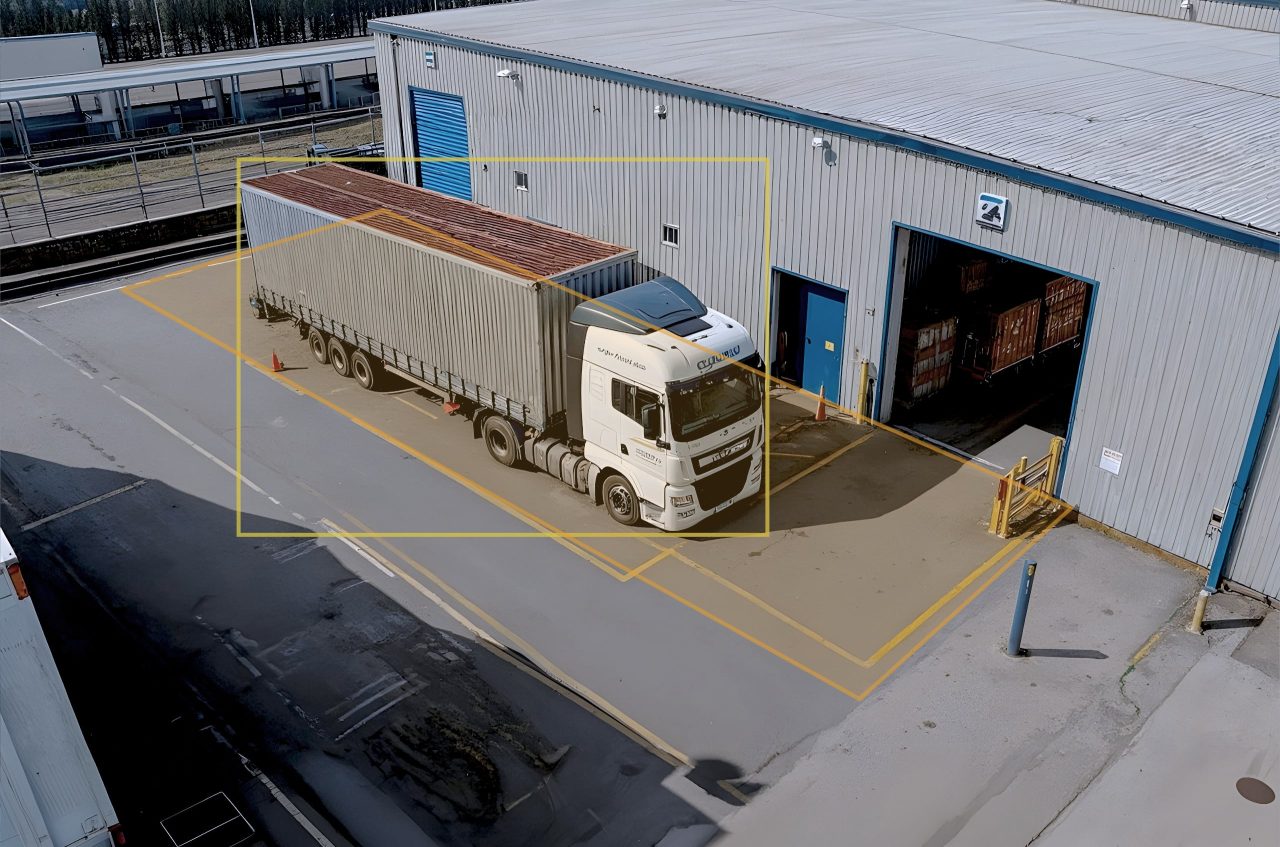

Transforming lean and efficiency with computer vision

Accelerate your ROI with AI vision-powered lean and efficiency

Lean and Efficiency Suite

Deliver high-impact use cases, ready to deploy where you need them.

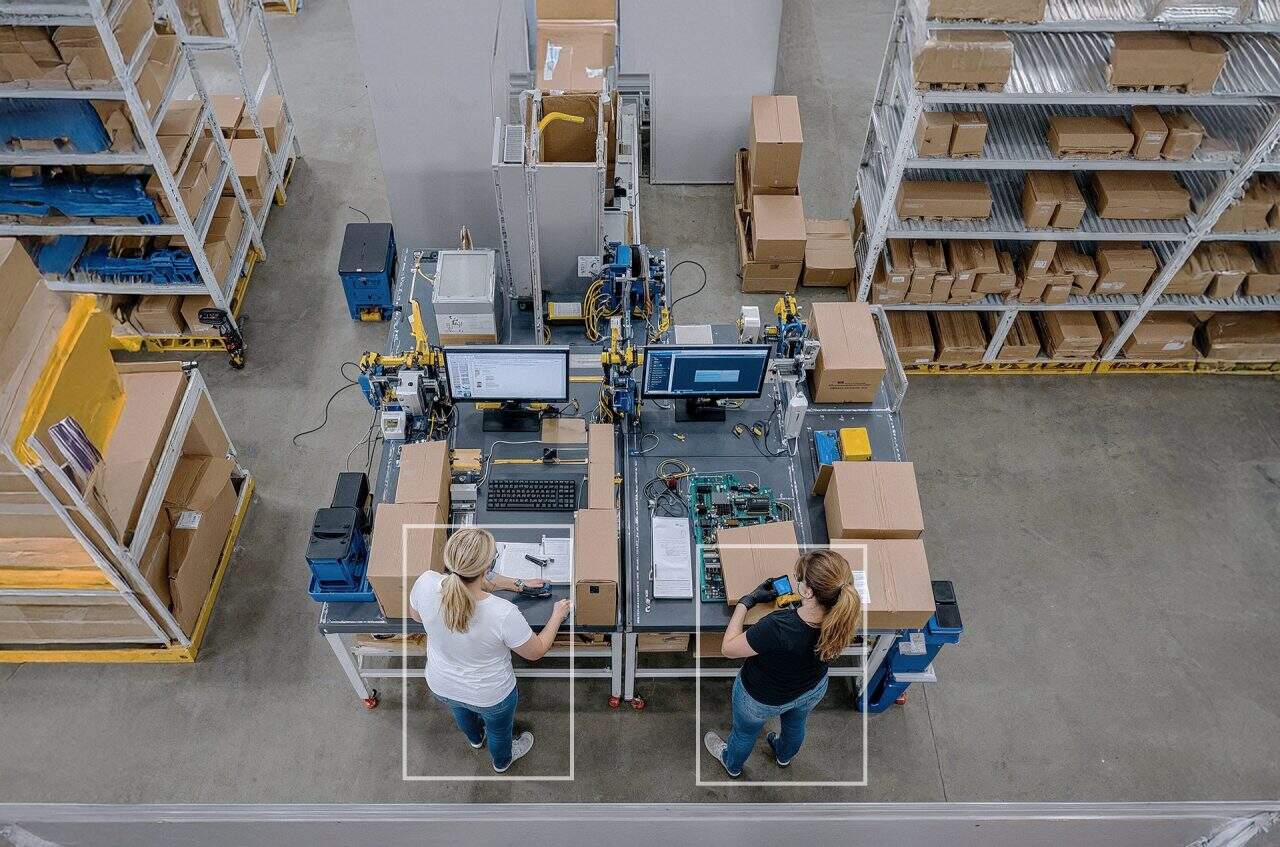

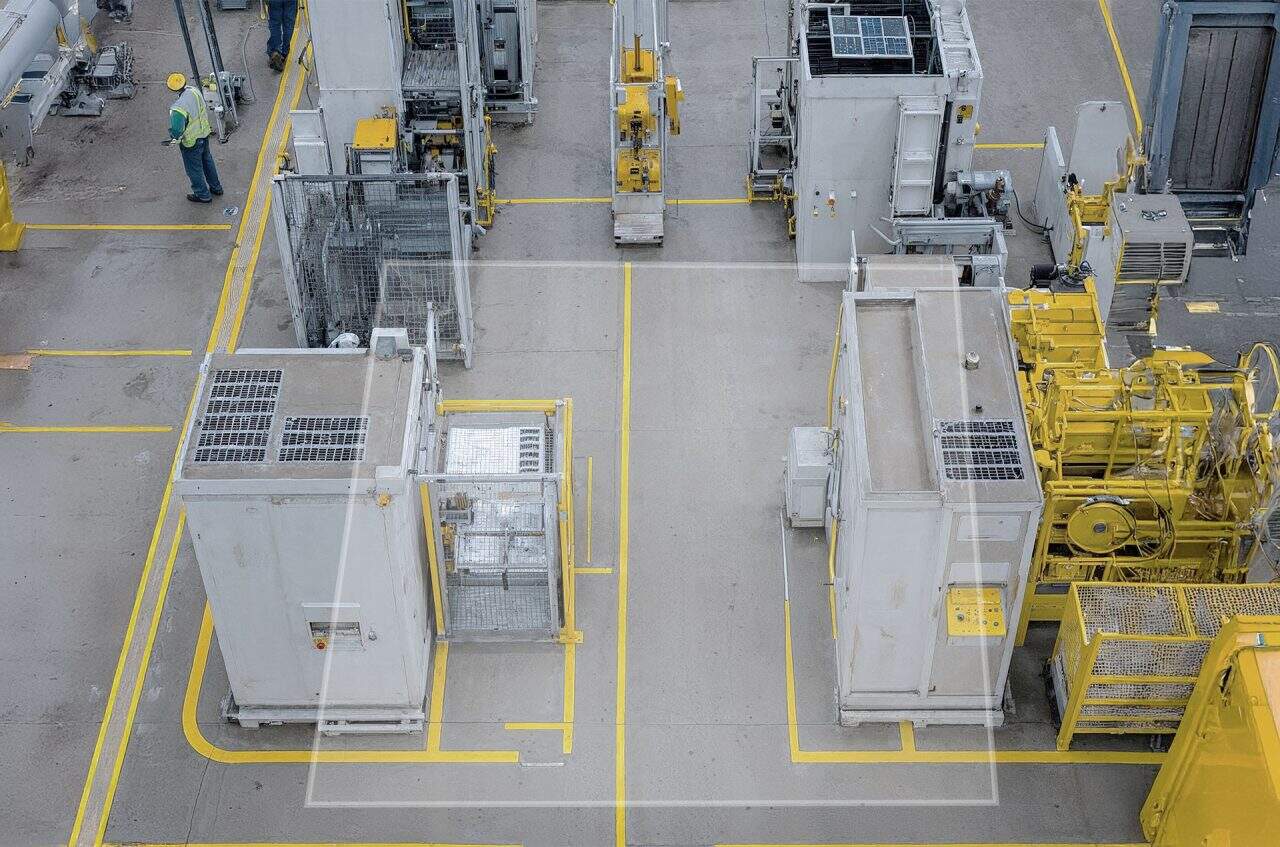

Work/idle workstation logging

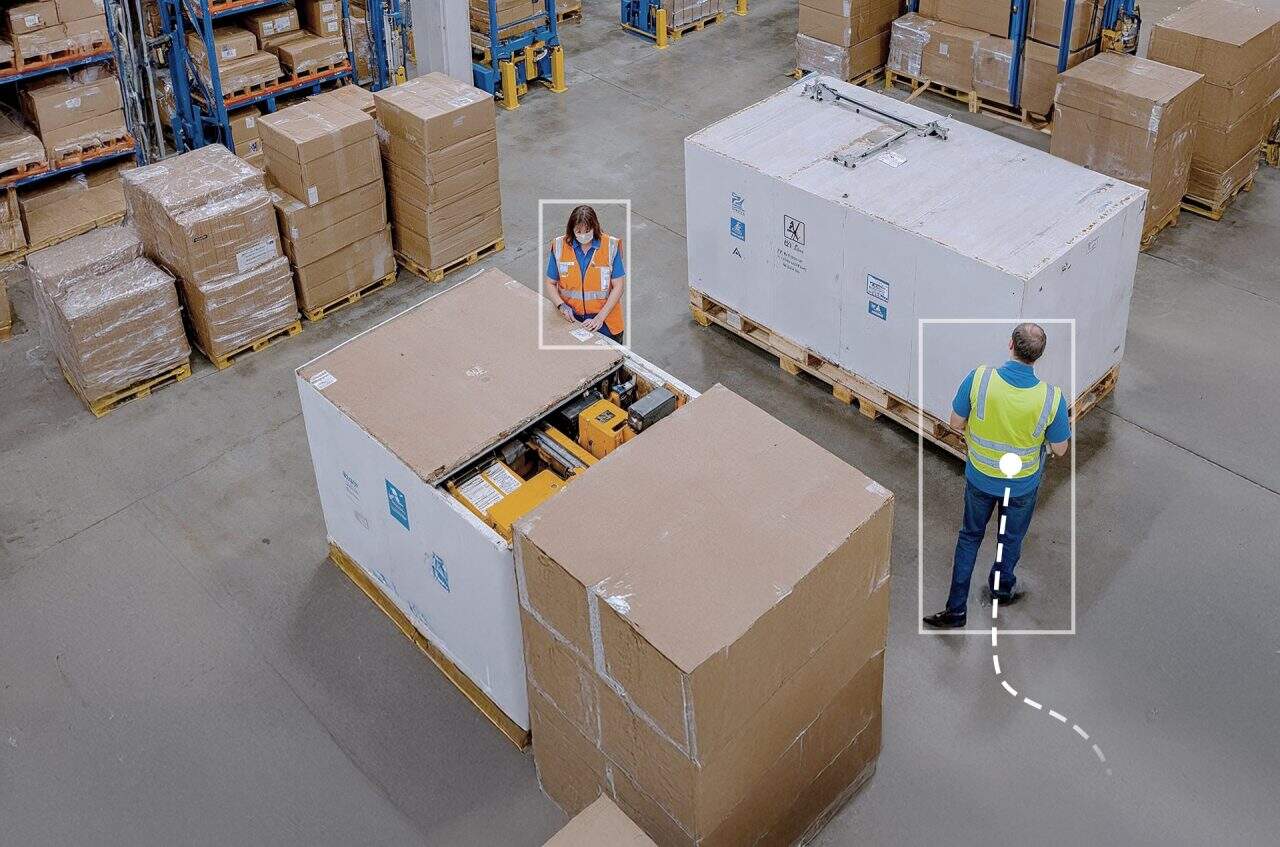

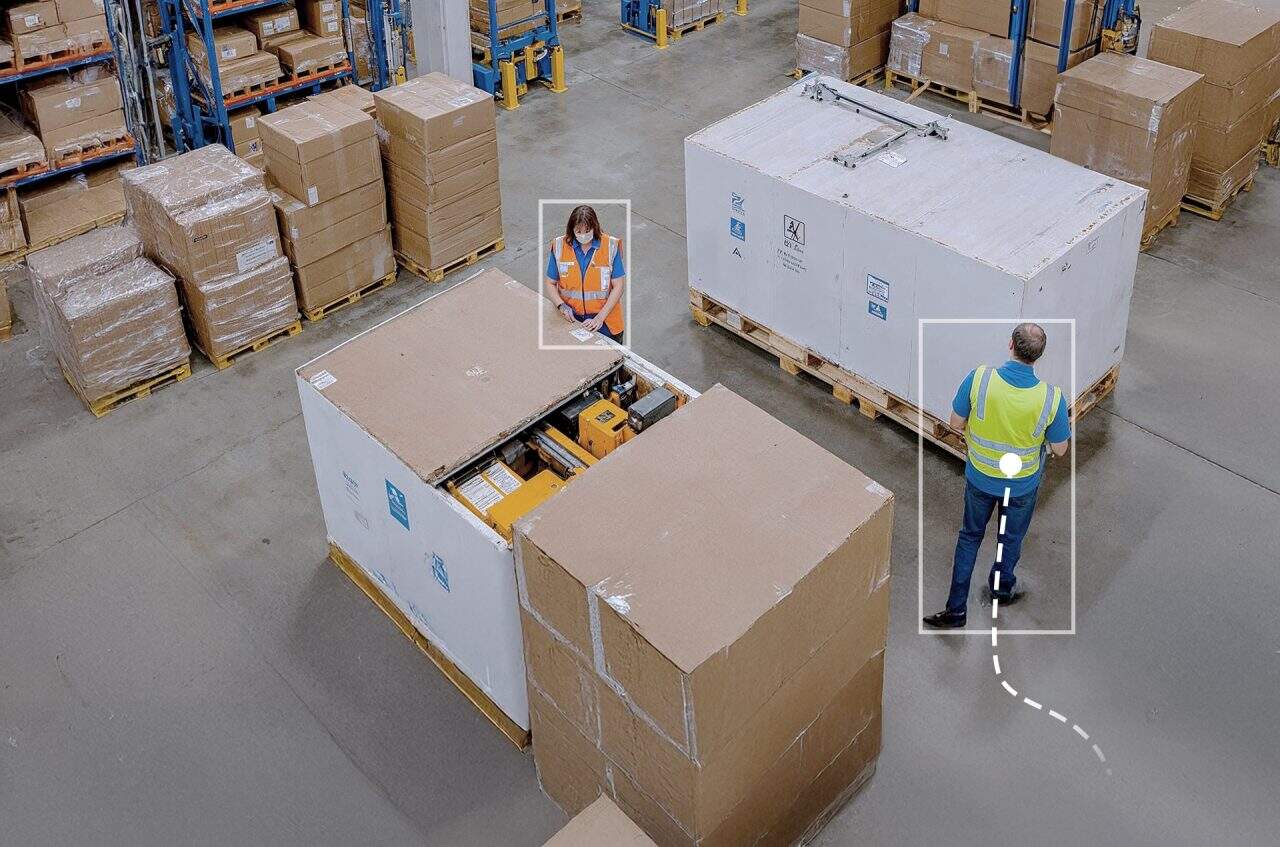

Non-value-add movement reduction

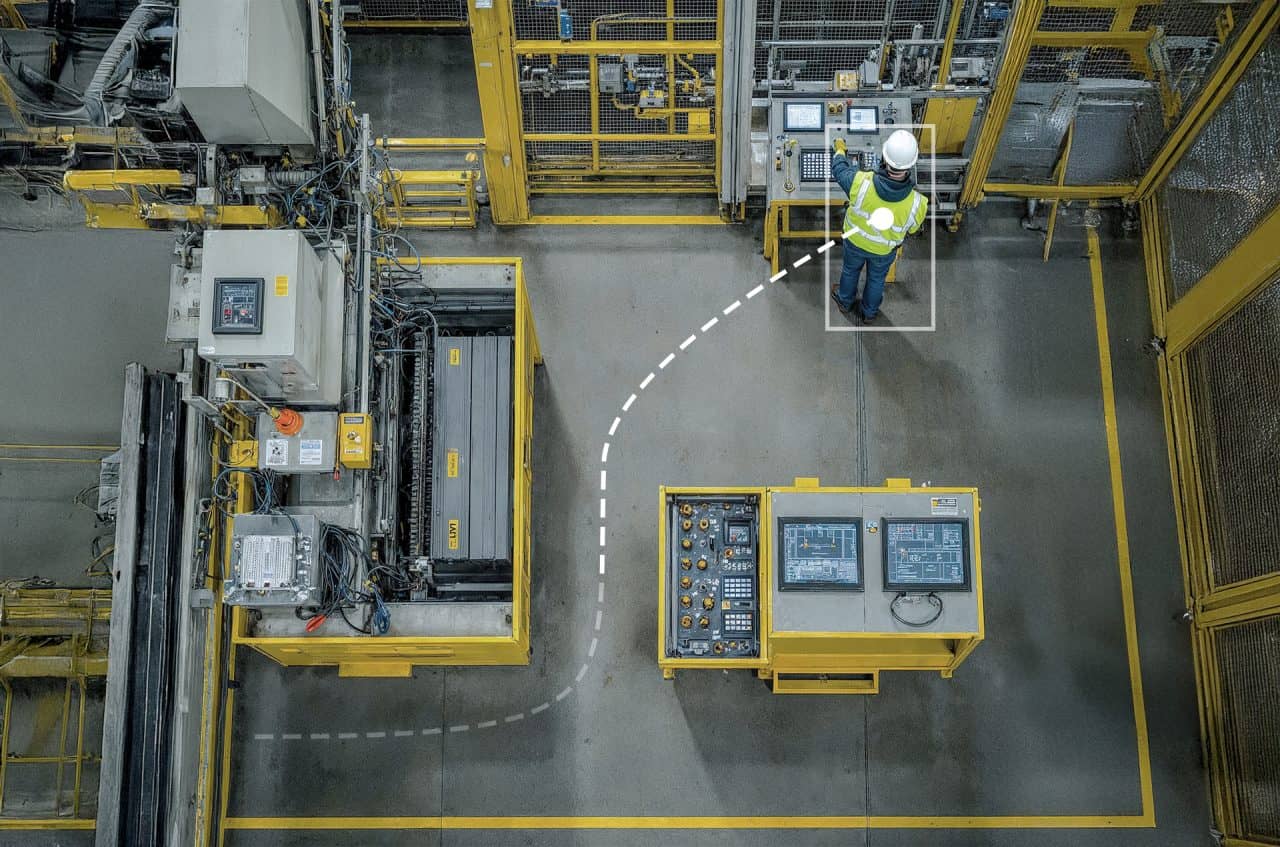

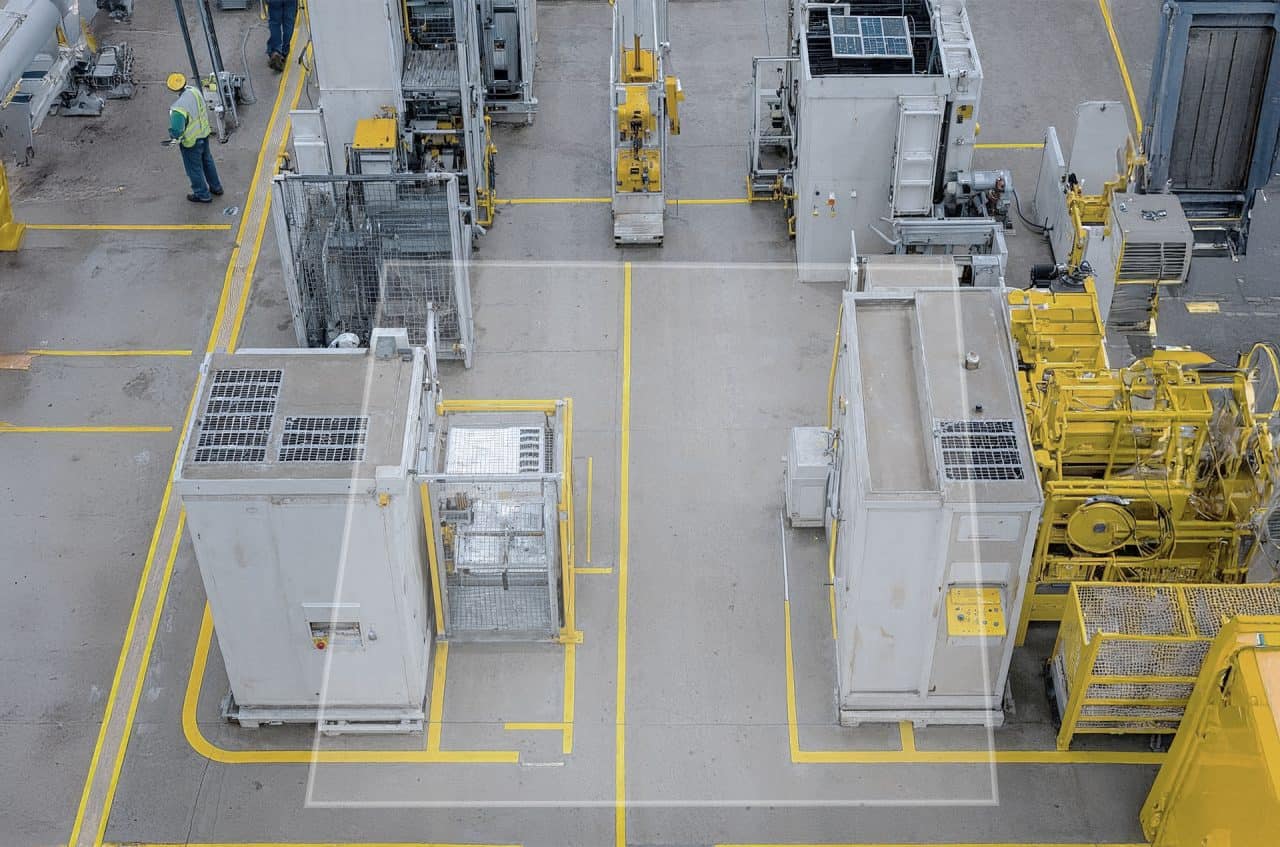

Machine utilization & downtime logging

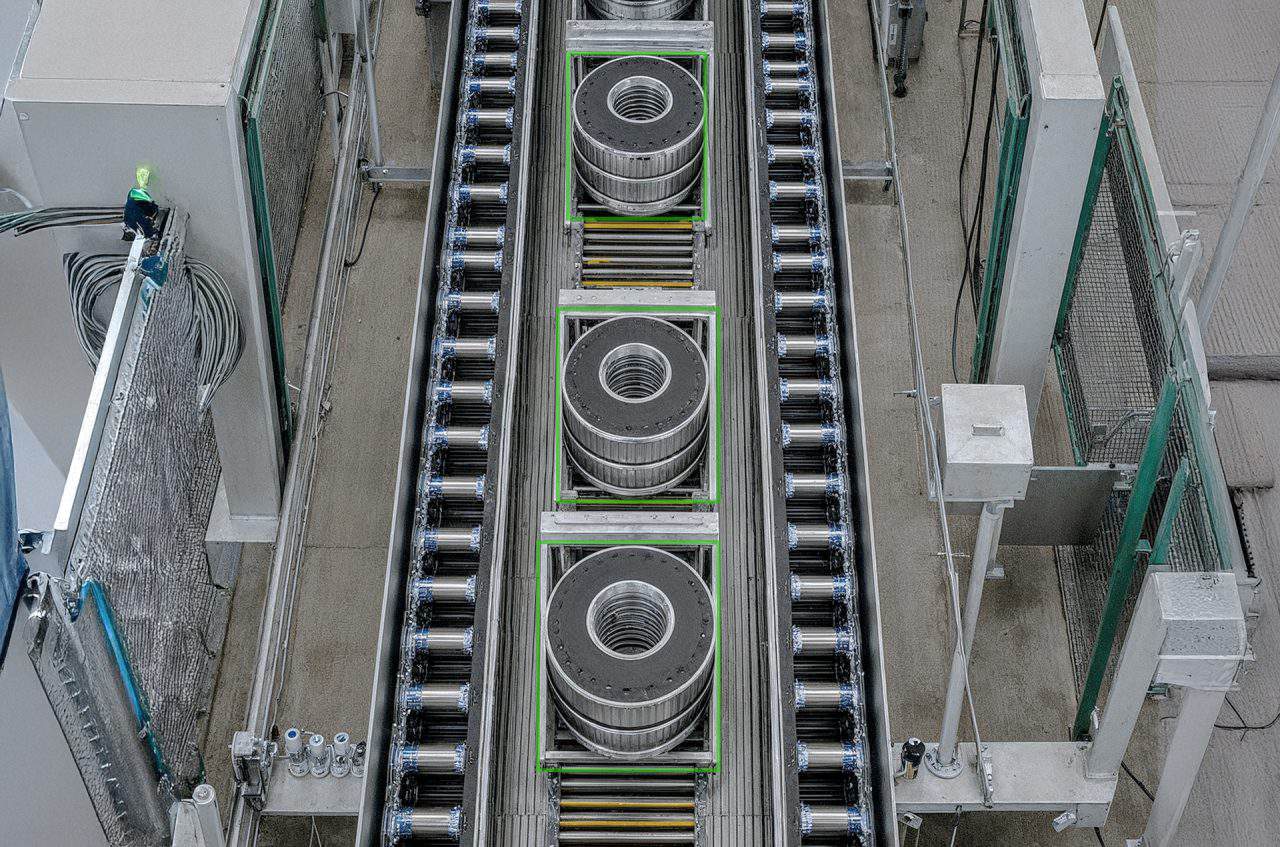

Material availability tracking

Process bottleneck identification

Workstation staffing compliance

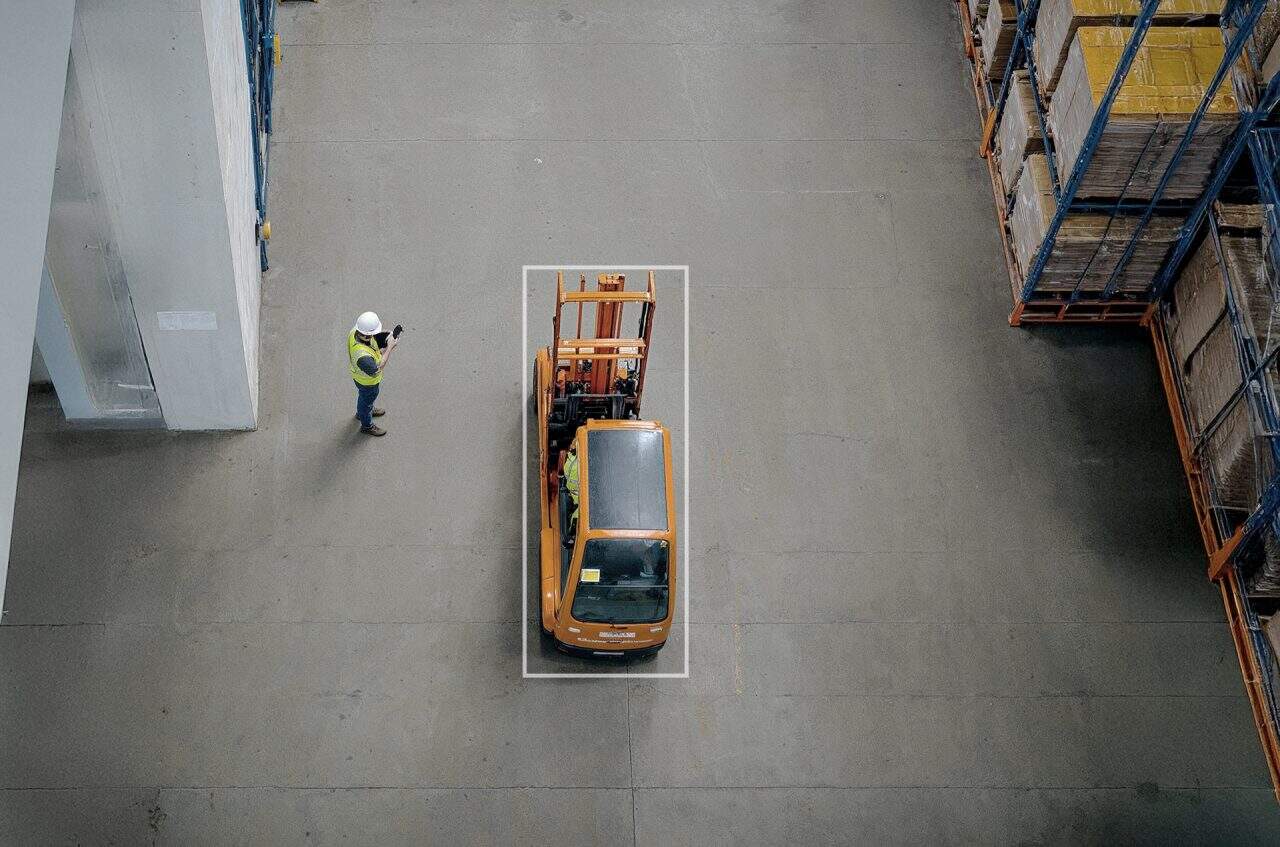

Ghost machine & out-of-position operator

Material flow rate monitoring

Activity monitoring over time

Asset usage optimization

Underutilized equipment alerting

Out-of-stock situation logging

Wait time and shift changeover logging

Train

Turn data into high-performance models.

Collect, manage, and refine high-quality data to create accurate and reliable AI models tailored to your business needs.

Build

Create and customize applications faster.

Develop and customize computer vision applications with an intuitive, flexible platform designed for enterprise-scale solutions.

Deploy

Scale seamlessly across devices

Rapidly roll out applications across multiple locations, ensuring seamless integration with existing systems and infrastructure.

Operate

Monitor, optimize, and evolve.

Maintain peak performance with real-time monitoring, automated updates, and enterprise-grade security.

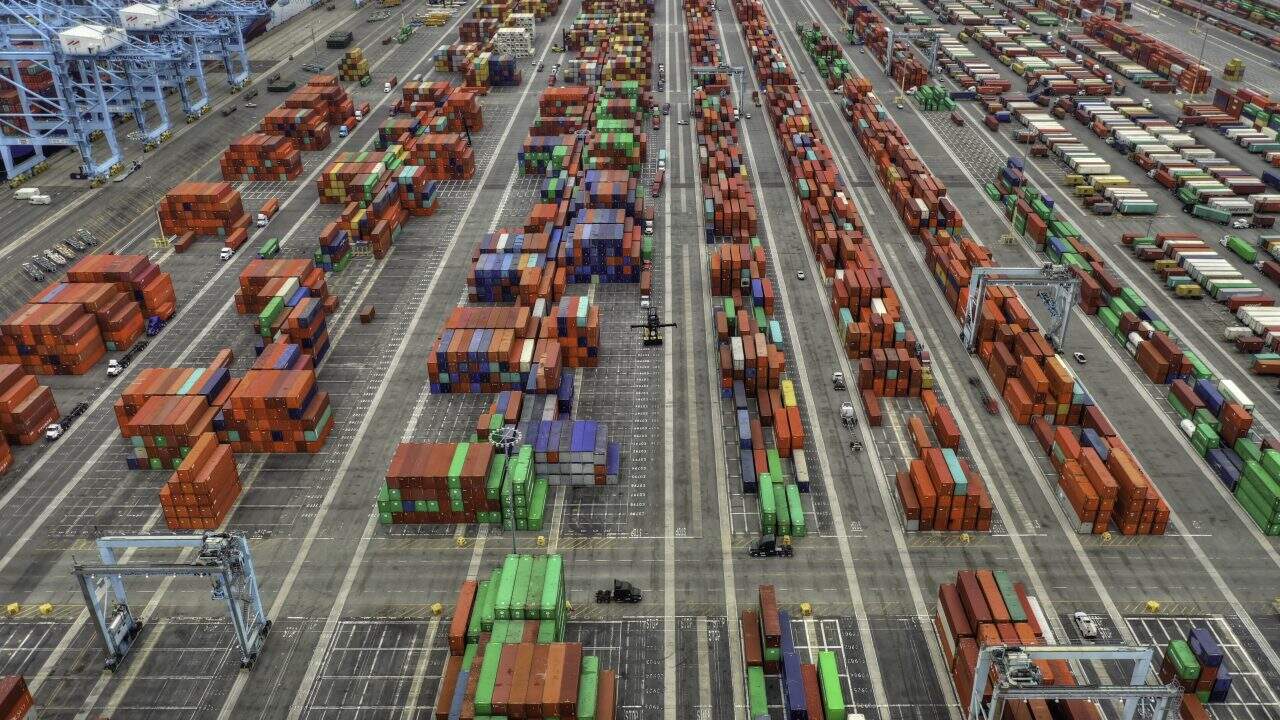

Transforming manufacturing with computer vision

Operational excellence starts here

Eliminate waste and boost OEE, continuously

Improve first-pass yield

Reduce downtime with real-time alerts

Faster decisions and automated feedback loops