Unforeseen safety incidents are costing industrial manufacturers as much as $50 billion per year.

According to a 2022 Forbes study, the impact of unplanned downtime, often from unforeseen safety incidents, can cost industrial manufacturers as much as $50bn annually1. Across the global economy, a Siemens report of the same year concluded that unplanned downtime wiped out 11% of the yearly turnover of all Fortune Global 500 companies (increasing from $864bn in 2020 to a staggering $1.5tn a year by 20222). With this trend continuing apace, the 2025 estimate is expected to easily surpass $2.5tn.

Perhaps even more alarmingly, the International Labour Organization (ILO) benchmarked that safety incidents alone are responsible for a loss of 4% of Gross Domestic Product (GDP) globally3. In this paper we outline that far from these trends further eroding margin, AI Vision – and specifically the viso HSE Suite – have already turned the tide for early-adopters of this technology. Aggregated research from several leading consultancies and global trade organizations indicates real-time monitoring with AI Vision can already reducing workplace accidents by 25–40% and resulting machine downtime by up to 20-30%.4

How AI Vision became the foremost development in eliminating downtime costs and safety risk AI Vision applications enable computers to ‘see’ and interpret the world around them through both images and videos, simulating human understanding. When these applications are used to power safety monitoring systems it becomes possible to detect unsafe behavior in real-time.

How AI Vision became the foremost development in eliminating downtime costs and safety risk

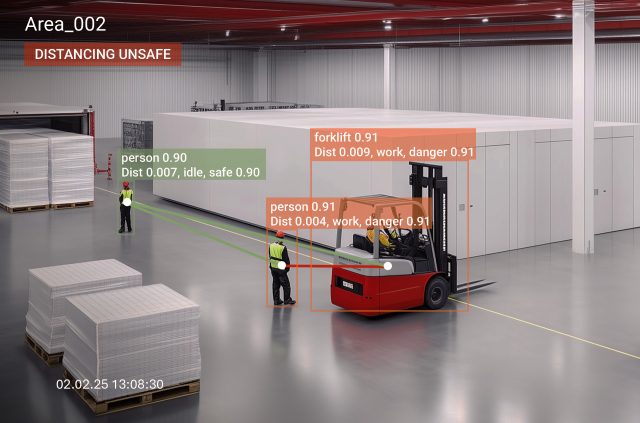

AI Vision applications enable computers to ‘see’ and interpret the world around them through both images and videos, simulating human understanding. When these applications are used to power safety monitoring systems it becomes possible to detect unsafe behavior in real-time.

Worker safety monitoring – ensuring compliance with safety protocols – using vision-based Personal Protective Equipment (PPE) and behavior monitoring is increasingly effective:

- Installing cameras at critical entry points to detect helmets & vests.

- Monitoring restricted zones and dangerous equipment with CV to detect unauthorized access or risky behaviors

- Using pose estimation to detect slips, trips, or fatigue-related postures