Designated material flow routes are critical to maintaining safety, efficiency, and order. These paths serve to keep equipment, raw materials, and in-process goods moving in a controlled manner. Thus, minimizing congestion by separating vehicles from pedestrians while preserving production flow.

Yet in daily operations, deviations from planned routes are common. Temporary obstructions, operator shortcuts, or a lack of enforcement result in forklifts and other material-handling vehicles frequently taking unauthorized paths. Over time, these deviations compromise safety protocols, introduce process inefficiencies, and increase the risk of collisions or bottlenecks.

Computer vision provides manufacturers with a means to automatically monitor material flow compliance in real-time, ensuring that routing policies are not only defined but consistently followed.

Why route deviations happen

Facilities invest heavily in mapping out optimal internal logistics with routes laid out to avoid congestion, ensure visibility, and comply with regulations around pedestrian-vehicle separation. Despite these efforts, consistent adherence is hard to achieve.

Common causes of route non-compliance include:

- Operators taking the shortest path to save time

- Temporary blockages (i.e., parked equipment or staged goods) that force rerouting

- Poor visibility or unclear markings in high-traffic zones

- Inconsistent protocol adherence across shifts or teams

- Lack of real-time supervision or enforcement

The reality is that these deviations often go unnoticed or unreported. But over time, they contribute to the occurrence of safety incidents, increased cycle times, and reduced accountability. In worst-case scenarios, a vehicle operating outside of its designated route can collide with personnel or damage equipment.

How computer vision enables route compliance

Using visual AI, firms can define material flow routes digitally and monitor them automatically using existing facility cameras.

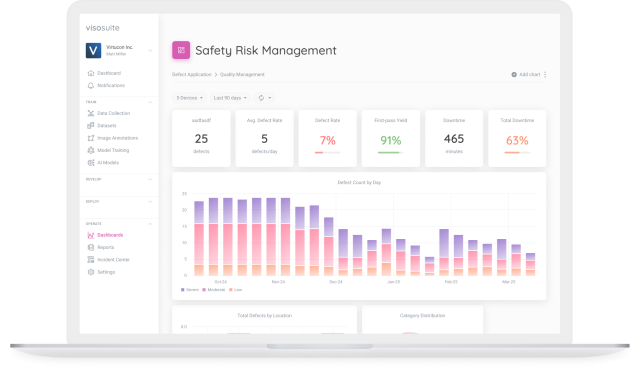

With Viso Suite, detection models analyze video streams at the edge, identifying and tracking forklifts, AGVs, and other transport vehicles as they move through the facility. The system maps actual movement paths against the predefined compliance routes. When a vehicle deviates from its assigned route, either crossing into restricted areas or bypassing waypoints, an alert is triggered.

Alerts can be delivered in real time, logged for later review, or used to generate compliance reports over time. Because routes and zones are defined directly within the platform, safety and operations teams can adapt them to reflect layout changes or evolving workflows.

Tracking the metric: deviations per route per day

Monitoring material flow route deviations per day provides a critical operational safety and efficiency metric. It enables teams to move from reactive oversight to proactive correction.

By identifying where and when non-compliance occurs, along with which drivers or shifts are most frequently involved, teams gain visibility into systemic issues:

- Are routes poorly marked?

- Are alternate paths being used due to congestion?

- Is there a training gap?

By understanding and acting upon these issues, teams finally get the chance to make systemic changes for the safety of their workforce. As an example, this data could support better floor planning, staffing decisions, and even vehicle coordination.

The cost of deviation

Even one unauthorized route deviation can result in significant downstream costs. A forklift entering a pedestrian-heavy zone introduces immediate safety risks, while detours through production areas can disrupt workflows or introduce contamination.

On average, the exposure per serious deviation, including potential safety violation, process disruption, or equipment damage, can be measured in thousands of dollars. This doesn’t include the hidden costs: decreased worker confidence in safety protocols, unreported near misses, or the increased risk of audit citations from regulators. Computer vision automatically builds in accountability: objective, real-time, and scalable.

Implementation with Viso Suite

With Viso Suite, manufacturers can deploy material flow route monitoring without investing in new sensors or hardware. The platform leverages existing IP camera infrastructure and edge computing to deliver fast, private, and secure processing.

Users define routes within the platform interface, set thresholds for alerts, and configure rules based on vehicle type, zone, or time of day. No matter the type of vehicle or machinery used, each facility can tune their detection models accordingly.

The system integrates with safety dashboards, audit logs, or even vehicle control systems.

Driving safer and smarter movement

Enforcing material flow route compliance is about enabling safer, more efficient operations. With vehicles following prescribed paths, everyone benefits: pedestrians know what to expect, operations run more smoothly, and bottlenecks are minimized.

Computer vision brings route compliance from a static map on a wall into a dynamic, live part of operations. It puts safety in first place with productivity as a close second. When the workforce sees that routing policies are actively supported by intelligent systems, adherence improves naturally, without the need for constant oversight.