In manufacturing environments where heavy machinery, large storage units, and fast-paced operations define the day-to-day, emergency exits can quickly become an afterthought. Boxes, pallets, carts, or equipment can unintentionally block exit paths, creating a serious safety risk and a direct violation of regulatory compliance standards.

For facility managers and EHS teams, ensuring that emergency exits remain unobstructed is a matter of protecting lives. In an emergency, a delay of even a few seconds due to a blocked exit could lead to catastrophic consequences.

While most companies rely on periodic visual checks and audits to identify obstructions, these traditional, manual methods have clear limitations. They’re time-consuming, inconsistently executed, and only capture violations after the fact. Computer vision offers a way to enforce exit visibility standards continuously, automatically, and at scale.

Why does the problem of exit obstruction persist?

Obstructed emergency exits are one of the most frequently cited violations during OSHA inspections and safety audits. Not because companies don’t value compliance, but because it’s easy for temporary obstructions to go unnoticed, especially in busy environments with limited floor space and constant movement.

Common obstructions we’ve seen include:

- Forklift drivers parking equipment too close to an exit

- Inventory teams temporarily staging items in front of doors

- Pallets of raw materials or finished goods stacked in front of exit paths

- Trash bins or recycling containers left in doorway clearances

- Maintenance carts or tools left unattended near exits

- Temporary signage, ladders, or cleaning equipment blocking doors during shift changes or setup

- Overflow from production lines or packaging stations encroaching on exit areas

- Employees propping open exits with objects for ventilation, then forgetting to clear them

- Extension cords or cables run through exit pathways, creating tripping and blockage hazards

In all cases, what starts as a short-term workaround can quickly become a serious liability.

Even with regular training and reminders, teams still face difficulties in enforcing clear-exit policies. Health & safety managers often only identify common violations during monthly walkthroughs or external inspections, increasing the risk of both fines and unsafe working conditions.

With visual AI, manufacturers can turn passive camera infrastructure into active compliance tools, detecting and responding to exit obstructions in real time.

How visual AI for obstruction detection works

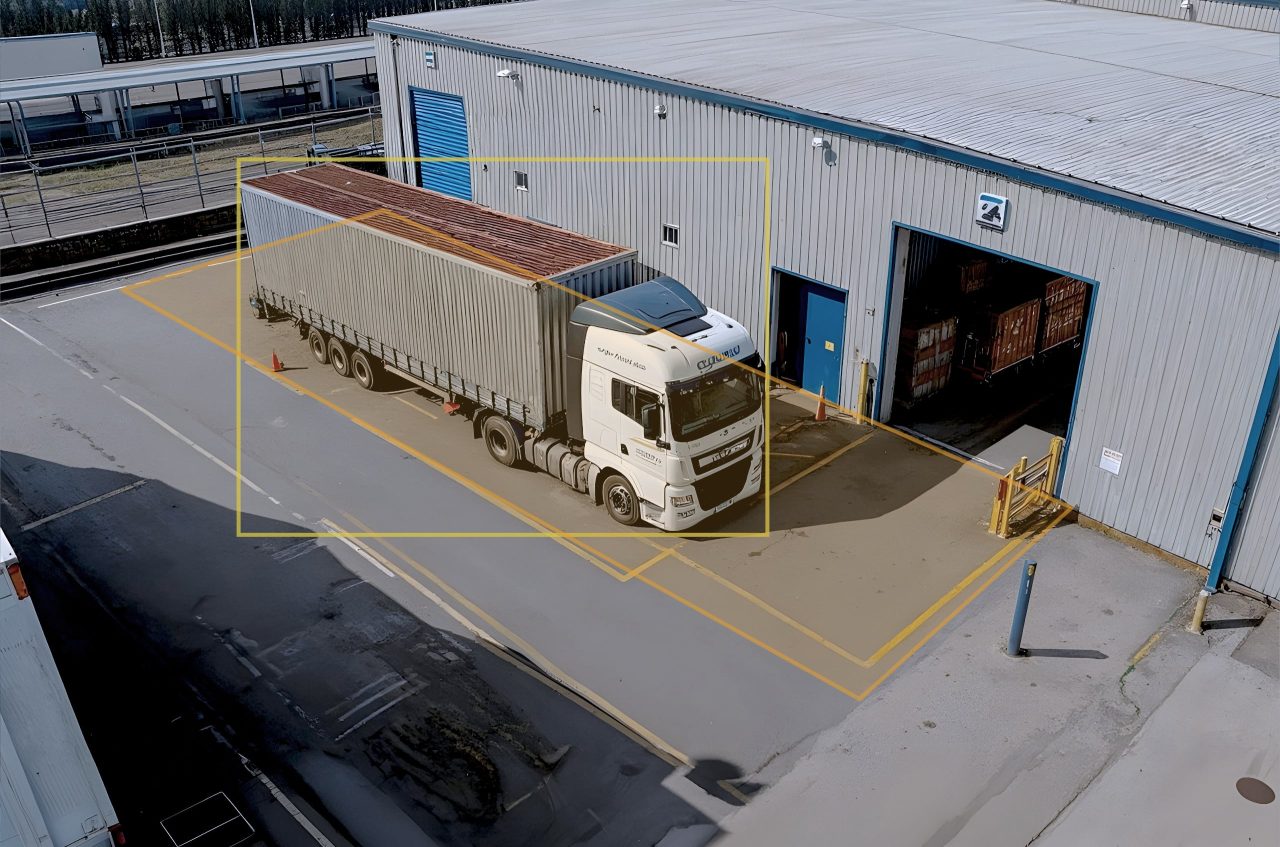

Exit obstruction detection uses computer vision models trained to identify both the presence of emergency exit doors and any physical objects that may block or obscure them. These models analyze live video feeds from existing security or facility cameras, flagging any blockage that persists beyond a configured threshold.

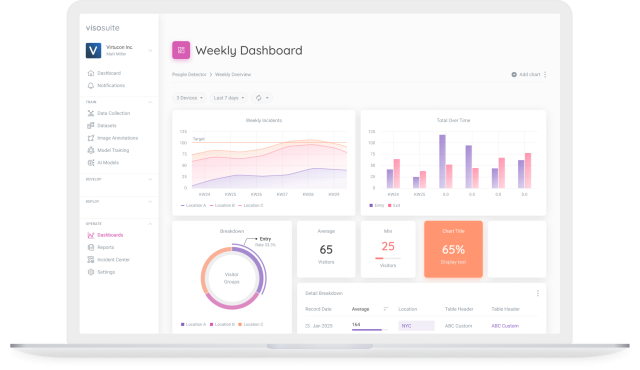

With Viso Suite, this detection can run at the edge, on local devices near the cameras, enabling low-latency alerts and reducing bandwidth usage. If an obstruction is detected, the system can trigger visual or audible alerts, send real-time notifications to facility supervisors, or log incidents for later review.

Over time, these detections are aggregated into weekly or monthly reports that quantify the frequency and duration of obstructions. This enables teams to monitor compliance trends across sites and identify problem areas, specific zones, teams, or timeframes where issues occur most often.

Measuring the value: compliance and risk avoidance

Blocked exit incidents aren’t just theoretical hazards, as they can translate directly into fines, citations, or shutdown risks. Regulatory bodies like OSHA and their international counterparts issue fines starting at $2,000 per violation, with higher penalties for repeated infractions or incidents that result in injury.

For facilities with dozens of emergency exits, consider the cost of just a few overlooked monthly violations. These reflect gaps in safety culture that may expose workers to unnecessary risk.

With automated visual monitoring, teams can establish a consistent, automated layer of oversight, turning what was once a reactive, manual task into a proactive safety protocol. Tracking metrics like “blocked exit alerts per week” gives EHS teams an actionable KPI that directly ties into both operational safety and financial risk management.

Scalable implementation with Viso Suite

Viso Suite makes it possible to deploy exit obstruction detection across multiple facilities without a large infrastructure overhaul. The platform connects directly to existing camera systems and supports flexible deployment across edge devices or hybrid edge-cloud environments.

Teams can define custom requirements to focus analysis on specific zones of interest, avoiding unnecessary alerts from other parts of the frame. Alert thresholds and response behaviors are fully configurable, ensuring that each facility can tailor the system to its own operational context.

Viso Suite also supports integrations with existing safety dashboards or facility management tools, so alerts and compliance logs can be centralized into current reporting workflows. This reduces administrative burden and simplifies audit preparation.

Toward a proactive safety culture

Blocked emergency exit detection is part of a broader shift in manufacturing from reactive safety compliance to proactive risk prevention. Rather than relying on spot checks and periodic inspections, teams can leverage always-on systems that catch and address issues in real time.

This approach improves compliance while reinforcing an organizational culture of accountability and awareness. Workers and managers alike benefit from knowing that safety-critical areas are being actively monitored, without the need for constant manual oversight.

In the long term, these kinds of systems help organizations move from simply avoiding fines to building safer, more resilient operations. Small oversights won’t escalate into major risks while safety protocols are upheld consistently and at scale.