In many industrial and manufacturing environments, certain tasks are classified as “two-person operations” due to their elevated risk. These may involve hazardous equipment, confined spaces, electrical systems, or high-pressure systems—any situation where the presence of a second worker is essential for oversight, response capability, and regulatory compliance.

Yet in real-world settings, ensuring that these tasks are consistently performed with the required staffing can be difficult. Whether due to time pressure, staffing gaps, or operational shortcuts, one-person execution of two-person tasks is an ongoing risk in many facilities.

Computer vision offers a scalable, real-time solution. By continuously monitoring designated zones, manufacturers can now automatically detect whether operations flagged as requiring two workers are being executed as intended.

Why two-person compliance still falls short

Despite clear safety rules and training, two-person task compliance is often left to manual supervision or assumed to be occurring based on scheduling and logs. In practice, this results in blind spots, especially in large facilities or complex shifts.

Non-compliance happens for several reasons:

- A second worker is scheduled but steps away temporarily

- Staffing shortages or delays cause one person to “get started alone”

- Workers underestimate risk and skip protocols for efficiency

- Supervisors have limited visibility into all active zones

- Manual audits only catch non-compliance after the fact

This creates a dangerous gap between policy and practice. A task that was supposed to be performed with oversight ends up being done alone, sometimes with no one else nearby to respond in an emergency. If an incident occurs, the company not only faces potential injury or fatality but also liability due to non-compliance with safety mandates.

Using computer vision to monitor task staffing in real time

With vision AI, companies can define zones or processes where two-person operations are mandatory and automatically verify compliance based on real-time video analysis.

When a task begins in one of these zones, the system checks for the presence of two individuals. If only one person is detected during a defined time threshold, an alert is triggered. These alerts can be configured to notify supervisors, log the event, or escalate depending on the criticality of the task.

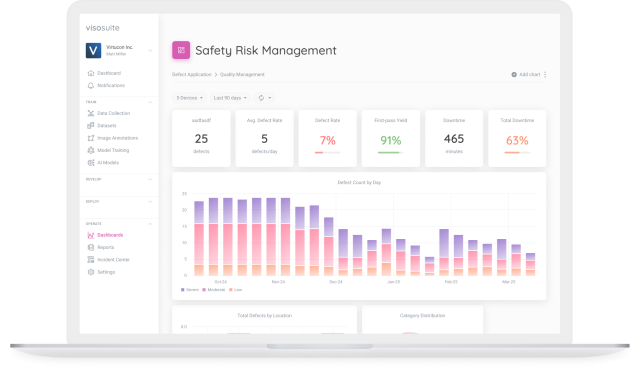

Using Viso Suite, this detection runs entirely on edge devices, processing the video data locally for low latency and privacy control. Detection rules are customizable to match specific workflows, such as confined space entry, lockout/tagout procedures, or machine maintenance tasks.

Key metric: non-compliant operations per day

Measuring non-compliant operations detected per day provides a direct way to quantify exposure to one of the most serious forms of operational risk.

Rather than relying on incomplete records or reactive incident reports, safety managers gain visibility into where and when lone work is happening during two-person-required tasks. The metric helps ensure compliance through proactive intervention: whether adjusting scheduling, reinforcing protocols, or redesigning workflows.

It also allows teams to benchmark progress over time, identifying which shifts, teams, or task types are most prone to protocol gaps.

Why it matters: the value of avoiding one non-compliant day

The cost of a single non-compliant task can be immense. If an incident occurs during lone work on a task that requires two-person oversight, the liability exposure can reach $2,000 per day or more, factoring in potential fines, injury claims, regulatory citations, and operational disruption.

Even in the absence of incidents, documented non-compliance can lead to failed audits, loss of certifications, or enforcement actions from workplace safety regulators.

Beyond financial penalties, persistent lone work erodes the safety culture. It signals to workers that rules are flexible and oversight is inconsistent, two conditions that lead to long-term risk.

Easy deployment with Viso Suite

Viso Suite enables manufacturers to implement two-person task monitoring without new hardware or complex integrations. The system connects with existing IP camera infrastructure and uses configurable detection zones to monitor compliance in critical areas.

The platform’s simplified interface allows safety teams to set up rules for different task areas, thresholds for how long a worker can be alone, and alerting behaviors tailored to specific operational contexts.

Because it runs at the edge, data stays within the facility, minimizing latency and ensuring privacy and security. All compliance events are logged and reportable, enabling audit-readiness and continuous improvement efforts.

Proactive safety in high-risk environments

Two-person tasks exist for a reason: the risks are too great for lone work. Having a second person present is a critical safeguard.

By automating the verification of these safeguards, companies shift from passive policy enforcement to real-time operational assurance. The goal is to ensure that essential protocols are followed even during busy, complex, or under-resourced periods.

Ultimately, the impact is both cultural and operational. Teams see that safety policies are actively supported by the company, beyond the writing in handbooks. And managers get to act on facts, not assumptions, when it comes to staffing critical tasks.

With solutions like Viso Suite, two-person compliance becomes enforceable, measurable, and scalable, transforming one of the most difficult-to-monitor safety rules into a source of continuous protection.