Operational efficiency: the future sees you coming

The industrial landscape isn’t changing. Industrial transformation is accelerating that change, with technological disruption ripping up the old rule books, and a focus on operational efficiency like never before. Business operations have to reduce wasted effort, identify bottlenecks and address performance losses under increased scrutiny.

The AI-powered computer-vision market is surging from $26.55 billion in 2025 to $473.98 billion by 2035, a near 30% annual growth rate that eclipses every other applied-AI category.

For operations management and finance leaders, this isn’t about experimenting with another technology layer. More, it is about unlocking a compounding ROI engine, where machines that see can also decide, optimize, and deliver measurable outcomes in months, not years. This includes measurable gains in OEE improvement.

“The next wave of productivity won’t just simply be automated. Instead, it will be vision-enabled, powered by the dawn of true visual intelligence. Intelligent operations driving operational efficiency like never before”

– Nico Klingler, Co-CEO and Co-Founder, viso.ai

From blind automation to intelligent operations

For decades, factories, warehouses, and facilities have collected seemingly endless amounts of footage. Millions of frames with minimal insight drawn from them. Today, edge computing and deep learning have changed the equation. Every process can be made visible, measurable, and intelligent. Cameras are no longer passive sensors. They are nodes in a real-time decision network. Edge AI makes this possible by running inference where the work happens: fast, local, and low-latency

“When cameras become decision-makers, vision stops being a sensor. Powered by today’s visual intelligence, AI Vision is not optional, but an essential strategy to be ignored at its peril.”

– Gaudenz Boesch, Co-CEO and Co-Founder, viso.ai

Four ROI Levers that change the game

Together, these levers map directly to OEE improvement: quality (defects), performance (throughput), and availability (downtime).

1. Quality and yield: up to 85% defect reduction

AI Vision systems spot surface, assembly, and labelling defects with millisecond precision. Case deployments across global manufacturing show up to 85% defect reduction. That means lower scrap, fewer warranty claims, and greater customer satisfaction levels. Crucially, it also increases first-pass yield. Process improvements that drive efficiency and productivity reduce operational costs and drive down any production loss.

2. Throughput and fulfilment: 30% faster order speed

Vision-guided systems, cameras and models, and real-time line analytics, optimize layouts and picking. That’s 30% average throughput improvement, according to large-scale factory studies. Cycle-time reductions and production times improving cascade into higher OEE and lower per-unit costs. This is repeatable OEE improvement across shifts and sites.

3. Uptime and maintenance: predict before you pause

Anomaly-detection models can interpret vibration, thermal, and alignment cues to flag issues before they cause equipment failure and subsequent downtime. Plants, facilities, and factory floors adopting vision-based predictive maintenance report between 20% and 40% less unplanned downtime. That availability gain is a core driver of operational efficiency.

4. Overhead and efficiency: Edge inference saves costs

Running inference at the edge cuts cloud fees, slashes latency, and reduces manual inspection workload. Real-time insight replaces post-hoc analysis, freeing skilled teams for higher value-adding tasks. Edge AI makes this sustainable at scale by keeping decisions local, fast, and cost-efficient.

Together, these levers make the financial case clear: AI Vision shifts automation from a cost center to a continuously compounding, long-term investment. Operational excellence, as typified by OEE improvement, is one of the clearest board-level proof points, with real time data available.

Architecture that accelerates payback

A vision-first operation thrives on three technical foundations:

1. Edge AI processing → Immediate insight with zero lag

- Edge AI enables low-latency decisions without round-trips to the cloud.

2. Continuous learning loops → Every frame improves model accuracy

3. Hybrid Edge-to-Cloud orchestration → Governance and scalability built-in

This architecture allows real-time decisions at the edge while feeding aggregated intelligence to executive dashboards. This kind of modern, visual intelligence system and integrated processes turns factory-floor visibility into boardroom foresight. It also speeds time-to-value by making OEE improvement measurable from the first pilot.

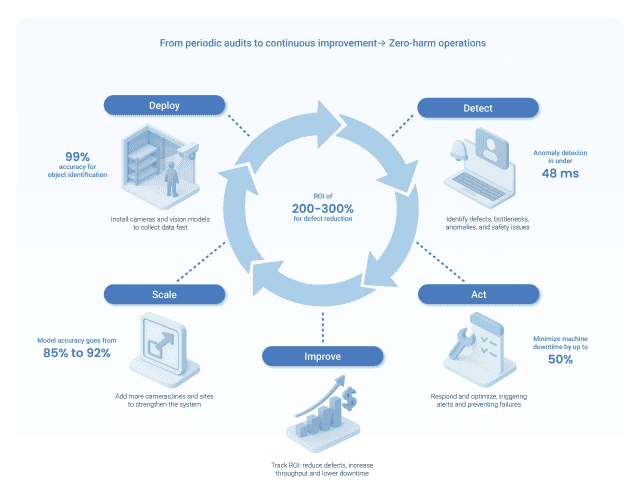

The Flywheel effect: from deployment to compounding value

AI Vision creates a self-reinforcing cycle, or what we consider to be a ‘Flywheel’.

- Deploy → Install vision systems

- Detect → Spot issues in real time

- Act → Respond and optimize immediately

- Improve → Measure tangible gains

- Scale → Expand to new use cases

Crucially, the flywheel leads to better insights and improved learning. Better data trains better models for each use case, compounding the investment return for that use case. We see the flywheel operating as follows.

1. Deploy and capture

Install cameras and vision models to collect real-time visual data across operations

→ Continuous visual intelligence begins and establishes a baseline for visibly higher OEE scores.

2. Detect and understand

AI identifies defects, bottlenecks, anomalies, and safety issues instantly

→ Blind spots become measurable insights.

3. Act and optimize

Trigger alerts, adjust processes,and prevent failures before they happen

→ Reactive operations become proactive with faster loops that sustain OEE improvement.

4. Measure and prove

Track ROI: defects ↓85%, throughput ↑30%, downtime ↓40%

→ Results justify expansion and quantify OEE improvement in operational terms.

5. Scale and compound

Add more cameras, use cases, and lines. More data = smarter models

→ Each deployment strengthens the system, especially when Edge AI keeps inference fast and cost-controlled across sites.

Then the cycle repeats: faster, smarter, more valuable.

The result? In each new use case, additional cameras, models, and lines, and the resulting data and insights, strengthen and improve the output. The longer it runs, the better the results, and the more predictive potential there is.

“Vision is the one industrial asset that doesn’t depreciate. It accumulates, appreciates, and accelerates. Every frame, observation and alert fuels a smarter system.”

– Nico Klingler, Co-CEO and Co-Founder, viso.ai

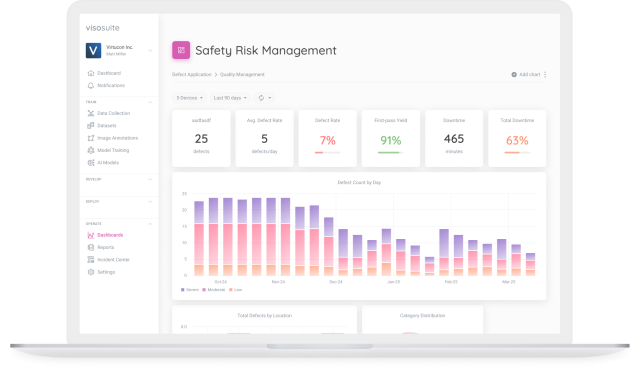

From footage to foresight: the CFO view

Key takeaways for executives? With AI Vision, finance teams can now treat visual intelligence like any other capital asset, and track effectively with measurable KPIs, including:

- Defect rate (typically reducing it by up to 85%)

- Throughput (increasing between 15-30%)

- Unplanned downtime (often reduced by up to 40%)

- Audit and inspection labor required (becoming 30% lower)

Most importantly, OEE improvement is the roll-up metric connecting quality, performance, and availability to ROI. The bottom-line impact from improved production processes can be considerable.

See. Understand. Act.

The companies winning this decade will be those that turn sight into strategy. Cameras won’t just watch. Instead, they will decide. Rather than letting cameras sit idle, today’s innovators and operational leaders have already turned them into intelligent collaborators. Eyes that never sleep that cut waste, prevent downtime, and grow margin.

Sources used in the article include:

- WEF / McKinsey (“Global Lighthouse Network: Fourth Industrial Revolution Performance Metrics (2022))

- McKinsey & Company (“The Next Normal in Manufacturing AI” (2023))

- PwC (“Industry 4.0 and the Smart Factory” (2022 update))

- Capgemini Research Institute (“Smart Factories at Scale” (2023))