The talent safety crisis is here. The numbers paint a sobering picture of workplace safety oversight in 2025. Across the US, OSHA confirms that they have just 1,850 HSE inspectors responsible for 130 million workers spread across 8 million worksites. That averages out to one compliance officer for every 70,000 workers, and if everyone were to visit each worksite once a year, that would require 11 worksites to be visited every day

Meanwhile, 385 workers die every day from workplace incidents, according to the International Labour Organization, and over 70% of manufacturers report difficulty hiring qualified safety professionals. Even when considering the total scale of the health and safety workforce, which numbered 163,700 in 2024, according to the U.S. Bureau of Labor Statistics (BLS), the ratio remains extremely low, with just one HSE specialist for every 794 workers.

The numbers simply don’t add up. Demand for safety expertise far exceeds the capacity of skilled professionals, and the gap is widening.

The safety talent crisis: manual oversight is an unsustainable reality

Traditional safety management has always been resource-intensive, requiring specialized knowledge that takes years to develop. But today’s industrial environment has pushed this model beyond its breaking point.

Firstly, with an aging workforce, veteran safety professionals are retiring faster than new entrants can replace them, creating a widening knowledge vacuum. The capacity of this workforce was already stretched thin: traditional audits and inspections cover only a fraction of actual working time (studies show as little as 8–12% of real operations are observed directly).

Additionally, burnout and turnover have a major impact: overtime, multi-site responsibilities, and constant pressure accelerate attrition, worsening the very shortage they’re meant to fill.

The ripple effects are immediate and costly. Delayed hazard spotting translates directly into more incidents, more downtime, and rising insurance costs. For executives, the liability exposures are daunting. And for safety managers, the physical impossibility of being everywhere at once means critical safety gaps go unmonitored.

HSE solutions: AI Vision as the force multiplier for safety talent

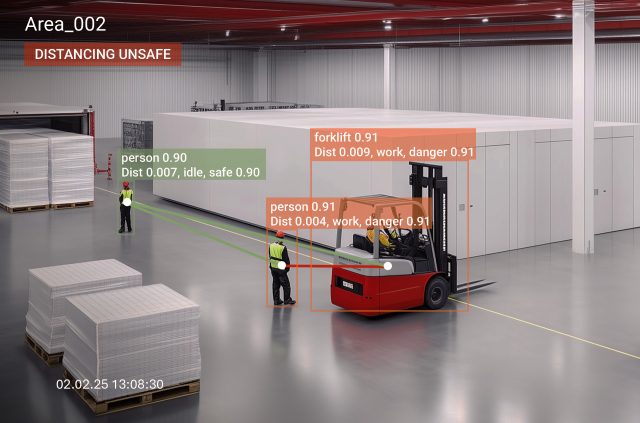

Enter AI Vision – not as a replacement for safety professionals, but as the ultimate force multiplier that transforms how oversight operates. Think of AI Vision as a tireless safety inspector: it never sleeps, never misses a shift, and never calls in sick. It monitors multiple sites simultaneously with unwavering attention to detail.

- 24/7 coverage: AI Vision systems continuously monitor facilities, identifying PPE non-compliance, unsafe behaviors, near-misses, and blocked emergency exits in real time

- Beyond human capability: sophisticated algorithms analyze millions of data points to spot pre-incident indicators invisible to human observers

- Scalability: an AI system can provide the equivalent monitoring power of dozens of inspectors, moving observation coverage from under 12% to near 100%

This isn’t just incremental improvement – it fundamentally changes what’s possible in safety management.

Business outcomes that transform safety operations

For organizations grappling with the talent shortage, the business outcomes of AI Vision adoption are hard to ignore.

- Reduced injury rates: companies using AI Vision have reported up to a 40% reduction in workplace injuries thanks to earlier hazard detection

- Faster response: automated alerts cut incident response times from minutes to seconds, giving teams the critical time to prevent escalation

- Regulatory compliance: continuous monitoring ensures high standards are maintained despite limited staff availability

- Data-driven ROI: automated logs, video evidence, and analytics allow safety leaders to demonstrate measurable returns and justify investments to the boardroom

- Cost efficiency: AI systems provide continuous coverage at a fraction of the cost of equivalent human resources, reducing dependence on an increasingly scarce labor pool

The result: safety is no longer seen as a cost center, but as a strategic advantage that improves uptime, reduces claims, and protects reputation.

Redefining the role of safety talent with AI Vision

Perhaps the most significant shift is how AI Vision redefines the role of safety professionals themselves. Instead of spending hours conducting routine checks, safety leaders can pivot toward higher-value activities, such as interpreting AI insights and identifying systemic risks. It frees up more time to design prevention strategies and training programs, leading cultural change that embeds safety into daily operations.

This evolution addresses a long-standing challenge in safety management: how to move from reactive incident response to proactive risk prevention. AI handles the routine detection and surveillance – humans provide the judgment, strategy, and leadership that technology cannot. The outcome is a hybrid safety model – combining the precision and scale of AI with the human expertise needed to drive continuous improvement. Safety professionals don’t become less valuable, rather more so.

Implementation without disruption

Another advantage of AI Vision is its ability to integrate seamlessly with existing safety processes. Organizations don’t need to rip and replace their current systems. Instead, AI Vision augments what already works.

- Fast adoption: training requirements focus on interpreting AI insights, not learning complex new systems

- Minimal disruption: AI Vision layers into existing safety workflows, filling monitoring gaps without changing cultural foundations

- Scalable deployment: systems can start at high-risk sites and expand across facilities, providing flexibility for resource-constrained teams

For HSE managers already stretched thin, this means faster wins without overwhelming transition burdens.

The path forward: addressing the safety talent crisis

For organizations facing the dual challenge of a safety talent crisis and increasing regulatory demands, AI Vision is more than just a technological upgrade – it’s a strategic transformation. It makes comprehensive oversight achievable and sustainable, even with limited staffing. It shifts safety management from reactive to proactive. And it gives executives the confidence that safety risks are being managed with the same rigor as financial or operational risks.

In an era where every day 385 workers don’t make it home, the case for AI Vision goes beyond business outcomes – it’s about protecting lives at scale. And it is essential to remember – AI Vision is not about replacing people. It’s about enabling fewer safety professionals to achieve far greater impact. For organizations struggling to recruit and retain qualified staff, it’s the only sustainable path forward.