The cost of workplace injuries is far more than financial.

A single injury costs a company $44,000 or more, according to the National Safety Council (NSC). But the deeper cost? Lost trust, stalled production, reputational risk… and sometimes, tragically, a life.

Despite billions spent on PPE, training, and compliance systems, workplace injuries keep happening. Why? Because most current safety tools are reactive, fragmented, or dependent on manual enforcement.

But with AI Vision, industrial leaders have turned the tide, achieving up to 85% reduction in reportable injuries. So this isn’t the future. It’s being deployed today.

The challenge: safety that doesn’t scale

Manual processes and sporadic audits cannot keep pace with:

- Dynamic, high-risk environments (manufacturing, logistics, waste, construction)

- Complex workflows involving people, machines, and moving vehicles

- Shift-based operations where vigilance wanes over time

What’s more, existing CCTV systems are passive. They record, but they don’t protect themselves from workplace injuries.

Safety professionals are left responding after the fact, unable to detect risk in real-time or prevent escalation and workplace injuries before they happen.

So to meaningfully reduce workplace injuries, safety is now evolving from manual to machine-assisted, and from sporadic to scalable.

The AI Vision solution: always-on risk detection

AI Vision leverages smart cameras and edge AI to turn every zone, pathway, and process into a real-time safety checkpoint. These systems:

- Detecting PPE non-compliance, unsafe proximity, and high-risk behavior

- Monitoring pedestrian-vehicle interactions in real time

- Recognizing falls, fatigue, spill events, and unauthorized access

- Triggering alerts instantly – via lights, sound, mobile notifications

Because processing occurs at the edge, detection is fast and privacy is preserved.

But crucially, AI Vision doesn’t replace safety teams. It amplifies their reach, turning every shift into a monitored, protected environment.

Quick wins: three real use cases driving 85% fewer injuries

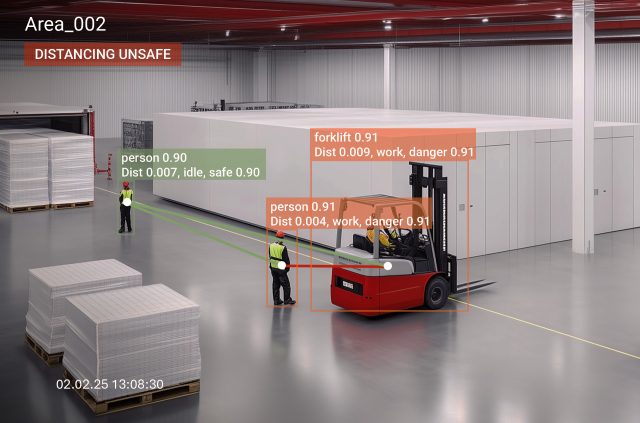

1. Real-time detection of unsafe proximity (forklifts and pedestrians)

By mapping zones and flagging distance thresholds, AI Vision alerts operators and workers to unsafe overlap, before collisions occur.

Why it matters: Sites using proximity alerting reduce near-miss incidents by over 70%.

2. Fall detection and immobility recognition

AI systems trained on human posture identify when a worker falls or collapses, triggering escalation protocols within seconds.

Why it matters: Early response cuts injury severity and improves return-to-work timelines.

3. Fatigue behavior monitoring

Subtle motion patterns – slowed walking, head nodding – tracked by AI to flag fatigue, especially in shift workers or vehicle operators.

Why it matters: Fatigue is linked to 13% of industrial injuries, many of them serious or fatal.

Business impact and ROI

The numbers speak for themselves:

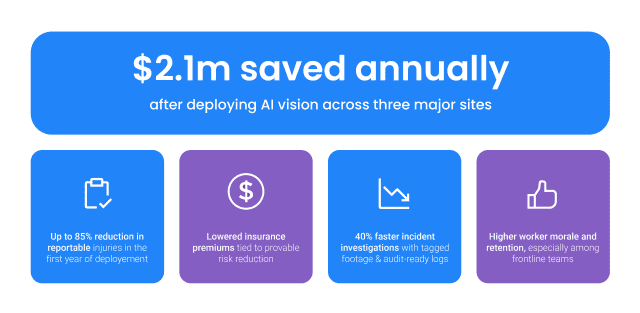

- Up to 85% reduction in reportable injuries in the first year of deployment

- Lower insurance premiums tied to provable risk reduction

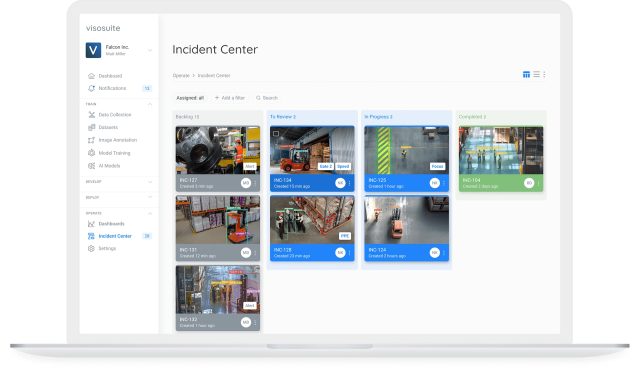

- 40% faster incident investigations, thanks to tagged footage and audit-ready logs

- Higher worker morale and retention, especially among frontline teams

One logistics customer reported saving $2.1m annually by having deployed AI Vision across three major sites.

This is safety that protects both lives and margins.

Why traditional safety isn’t enough

Most safety systems are built around reactive enforcement:

- Training only works if behavior doesn’t slip

- Cameras only help after reviewing hours of footage

- Checklists don’t scale across large teams and dynamic workflows

AI Vision provides continuous enforcement, without overburdening teams or relying on memory and vigilance. It closes the “awareness gap”, the space where most injuries occur.

Addressing concerns: trust, transparency, and technology

AI Vision systems are designed with:

- Edge-based processing (no cloud video storage)

- Anonymized detection (no facial recognition)

- Configurable alerts by zone, behavior, or risk level

Unionized sites see better adoption when workers are involved in rollout, alert threshold design, and clear communication. When framed as support – not surveillance – trust increases.

Workers don’t want to be watched. They need protection. And AI Vision delivers.

What’s next: predictive prevention and smart safety twins

The future of workplace safety includes:

- Predictive risk modeling based on near-miss and behavior trends

- Cross-site safety benchmarking and global dashboards

- Digital twins of facilities that simulate safety scenarios

- AI-assisted root-cause analysis post-incident

AI Vision is not just preventing injuries—it’s evolving safety into a strategic, data-driven asset.

Final word: workplace injuries tackled by AI Vision

Injury reduction isn’t a dream: it’s a data-backed reality. With AI Vision, industrial leaders protect their workforce, cut costs, and build the kind of safety culture that scales. If you’re still relying on reactive systems, it’s time to see what you’re missing.