The silent culprits of lost efficiency are minor stoppages and excess handling caused by poor material replenishment. Running out of materials leads to unnecessary downtime, while overfilling leads to safety risks and costly waste disposal. Traditional methods of tracking material levels often rely on manual checks or incomplete data from disparate systems, resulting in a reactive approach to replenishment.

Material availability tracking with computer vision transforms this equation by enabling continuous, real-time monitoring of container fill levels across production areas. Instead of waiting for operators to flag near-empty or overflowing containers, the system provides a visual audit of material readiness, enabling supply teams to replenish based on actual need.

What the system measures

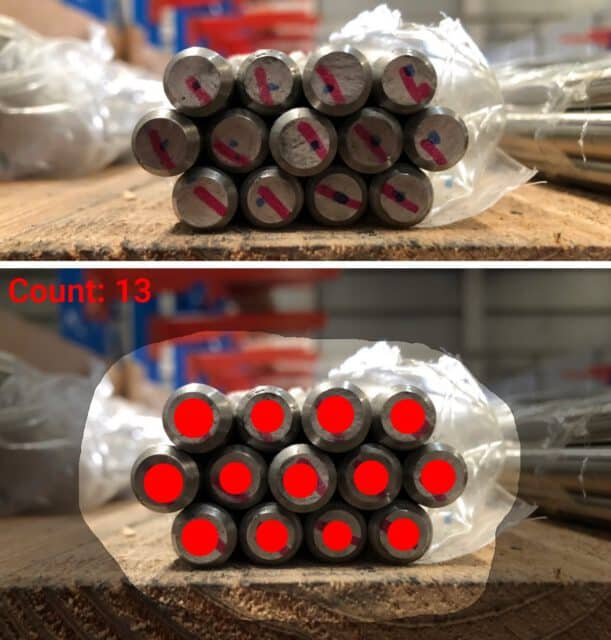

The system tracks fill levels of materials stored in bins, hoppers, or intermediate storage containers that feed into production lines. By using computer vision models trained to detect material presence and surface area coverage, the system can calculate whether a container is near full, half-empty, or approaching critical low.

Key operational metric

Containers at 80–90% capacity per hour

This threshold-based measurement allows teams to assess whether the material inventory is approaching overflow or depletion. These capacity flags are designed to trigger timely action to refill or stop material flow as needed.

Detection value:

If containers are allowed to overflow, the resulting waste can cost as much as $500 per event due to cleanup, lost material, and disposal. Conversely, if a workstation stops due to a lack of materials, even 15 minutes of downtime can cost thousands in lost production.

How material availability tracking works

Visual monitoring: Computer vision models monitor containers and material bins across the shop floor using existing camera feeds. Fill levels are estimated based on surface area, color contrast, or line-of-sight depth.

Threshold detection: Alerts are triggered when containers are nearing full or empty based on custom thresholds (e.g., below 20% or above 90%).

Live alerts and dashboarding: Supervisors and material handlers receive real-time notifications, enabling just-in-time refilling and preventing spillage or shortages.

Historical analysis: Data is logged and visualized in dashboards that help optimize material delivery routes, refill schedules, and container placement.

Industry use cases

Automotive manufacturing: Track raw material levels in component staging areas, such as body panels or fasteners, to avoid delays in assembly.

Electronics assembly: Monitor solder paste, reels, or adhesives in SMT and PCB stations, enabling timely replenishment and fewer line stoppages.

Food and beverage: Track fill levels of bulk packaging materials such as bottles, caps, or cartons to reduce waste caused by overflows or spillage.

Logistics and fulfillment: Monitor tote, bin, and carton fullness to better schedule transfers or packing staff, reducing labor redundancy.

5 business benefits

- Prevent overflow waste: Overflowing materials often lead to expensive disposal processes, contamination risks, and safety violations. Automated monitoring reduces these risks significantly.

- Reduce production interruptions: With timely alerts, teams can act before a lack of material stops a line, improving throughput and reducing downtime.

- Streamline replenishment: Refill operations become data-driven, reducing unnecessary labor, improving forklift routes, and optimizing delivery timing.

- Boost lean transformation: Material availability visibility supports just-in-time (JIT) principles by replacing inventory buffers with smarter refilling.

- Improve OEE and schedule adherence: By reducing line stoppages and material-related slowdowns, plants can maintain cycle times and improve their ability to meet targets.

![]()

Privacy and integration

All data is processed locally at the edge, ensuring no personal or identity-specific information is stored. Only visual estimates of material fill levels are captured and translated into actionable data. This system can feed directly into Manufacturing Execution Systems (MES), warehouse management tools, or replenishment scheduling systems.

From virtual guesswork to real-time clarity

Manual bin checks or reactive calls for material delivery are often too late or too early, creating waste in both directions. With computer vision-powered material availability tracking, operators and planners gain real-time clarity on what’s needed, when, and where.

The result is fewer surprises, more efficient operations, and a leaner, safer manufacturing floor. Material readiness becomes a measurable, optimizable part of the production process, delivering both cost savings and operational control.