In the world of lean manufacturing, waste comes in many forms. Among the most overlooked is non-value-added (NVA) movement: unnecessary walking, reaching, searching, or traveling that doesn’t directly contribute to the product or process.

Operators moving from station to station to retrieve tools, scan paperwork, or locate materials might be part of daily routines, but they can also reflect deeply rooted inefficiencies. When multiplied across workers, shifts, and weeks, these minor motions quietly siphon away time, energy, and throughput.

This is where Non-Value-Add Movement Reduction comes into play. By applying computer vision to measure operator motion in real time, manufacturers can quantify and eliminate unnecessary movement. This, in turn, frees up time, reduces fatigue, and unlocks capacity that’s already on the floor.

Why NVA movement matters more than you think

In many plants, teams rely on anecdotal observations or occasional time studies to assess layout efficiency. These methods are subjective, resource-intensive, and offer only a limited snapshot.

Without continuous, objective data, key questions remain unanswered:

- Are operators walking more than necessary?

- Are tools and materials placed optimally?

- Are best practices in motion economy being followed consistently?

What might seem like “just a few extra steps” adds up quickly. A single operator walking an extra 300 feet per hour (i.e., 6 trips of 50 feet) wastes nearly 1 hour per shift. Across a 15-person team, that’s 15 hours, or $500+ in daily lost productivity, depending on labor costs and output value.

Measuring motion with computer vision

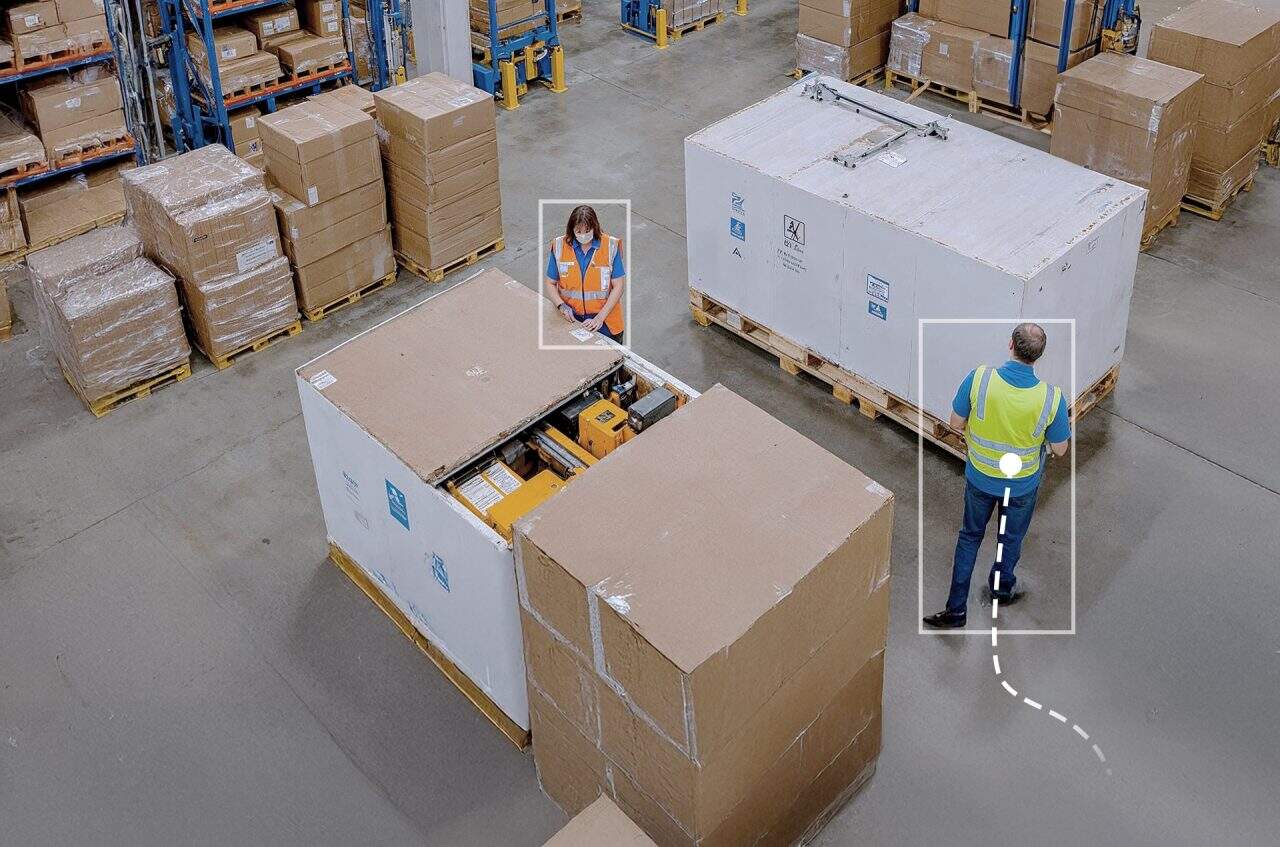

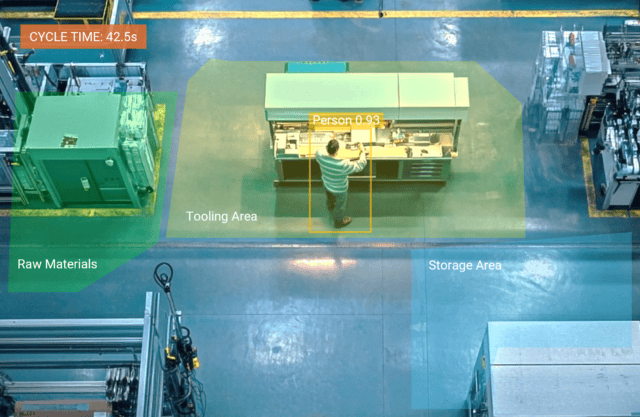

Enterprise-grade computer vision enables real-time monitoring of operator movement within predefined work zones. Using existing camera infrastructure, computer vision models track operator paths over time, identify patterns, and measure total travel distance per person or station.

Importantly, the system is designed to track movement, not identity, ensuring privacy while providing actionable data.

What the system tracks:

- Travel distance within the work cell or department

- Frequency and timing of out-of-zone excursions

- Repeated trips to common locations (i.e., supply rooms, tool cribs)

- Changes in movement patterns across shifts or layouts

These metrics are logged continuously and visualized on dashboards to support lean initiatives.

Key operational metric

Average travel distance/day

The core metric, Avg. Travel Distance per Operator per Day acts as a baseline for improvement.

With baseline data in hand, teams can:

- Redesign layouts to reduce walking distance

- Improve 5S placement of tools and materials

- Schedule material deliveries more strategically

- Implement and validate Standard Work

- Compare motion patterns across lines, teams, or products

Even a 10% reduction in NVA movement can drive $500/day in savings across a typical production team.

How it works

- Zone Configuration: Cameras are mapped to individual workstations, cells, or departments. No additional sensors or wearables are needed.

- Motion Detection: Computer vision identifies and follows the operator’s motion throughout the day. The system distinguishes between normal, value-added tasks (assembling, inspecting) and non-productive movement (i.e., leaving the station).

- Path Analysis: Motion paths are mapped, heatmapped, and analyzed for inefficiencies. Common travel routes, frequent destinations, and high-movement stations are highlighted.

- Data Visualization and Alerts: Supervisors receive reports showing daily movement data per shift or operator group. Outliers or layout issues can be flagged for immediate review.

Use cases across manufacturing

High-Mix Assembly

Identify excessive walking to shared tools or components that could be relocated or duplicated.

Consumer Goods and Packaging

Optimize operator stations to minimize time spent retrieving packing materials or printing labels.

Warehouse-Based Production

Track travel to inventory zones to better sequence replenishment cycles.

Electronics Manufacturing

Highlight NVA movement caused by poor material staging or unclear instructions in high-precision work.

6 business benefits of reducing motion waste

- Reclaim lost time: Reduce time spent walking, searching, or detouring, freeing up hours for value-added tasks.

- Support operator well-being: Minimize unnecessary motion to reduce fatigue and improve safety outcomes.

- Improve workstation layouts: Back facility layout decisions with hard data, no need for guesswork or outdated spaghetti diagrams.

- Benchmark across teams: Compare NVA movement across shifts, teams, or locations to identify best practices.

- Enable lean standardization: Support implementation of 5S and Standard Work with objective feedback on execution.

- Quantify ROI of changes: Measure motion reduction before and after changes to demonstrate impact and justify investment.

Privacy and integration

All motion data is collected passively through on-site cameras, processed at the edge, and stored securely. No facial recognition or identity tracking is used. The system captures movement paths only, ensuring full privacy for operators.

Data can be integrated into manufacturing dashboards, MES platforms, or lean program reporting tools to support continuous improvement efforts.

From anecdotes to evidence

Traditionally, identifying non-value-added movement has required time-consuming audits, stopwatches, and manual sketches. These tools are too slow for today’s dynamic operations, and often miss subtle but costly sources of waste.

With vision-powered motion analysis, manufacturers can move from anecdotal layout discussions to evidence-based action. Real-time data reveals how operators move, where inefficiencies lie, and how improvements affect behavior over time.

The goal is to not police teams, but instead empower them with the insight needed to design smarter, safer, and more productive workflows.