The safety gap you don’t see, but feel

In every industrial workplace – whether it’s a factory floor, a logistics hub, a chemical plant, or a construction site – there’s a fundamental disconnect, a safety gap, between how work is supposed to be done and how it actually gets done.

This disconnect is called the work-as-imagined vs work-as-done gap, and it’s one of the most persistent blind spots in safety management.

Engineers write detailed standard operating procedures (SOPs). Supervisors brief teams. Posters go up. But out on the floor, time pressure, familiarity, convenience, and routine often rewrite those rules in real-time. Dangerous safety gaps emerge, putting workers at risk.

The problem? When rules are bent or skipped – even in seemingly harmless ways – they open the door to serious risk.

What is procedural drift?

This gradual deviation from the documented process is known as procedural drift.

It’s not usually malicious. It’s a coping mechanism. A shortcut taken to meet production quotas. A faster method picked up from a co-worker. A judgment call made in the moment.

The UK Health and Safety Executive (HSE) reports that up to 34% of documented steps in high-risk tasks are routinely skipped or altered on the job. That’s not surprising, because most companies rely on:

- Infrequent, manual audits

- After-the-fact incident investigations

- Self-reporting of near misses or non-compliance

The safety gap between plan and reality stays hidden. Until something goes wrong.

The risk behind the routine

Think about the tasks your teams perform every day.

Entering high-noise areas. Operating forklifts in mixed zones. Handling heavy materials. Checking confined space ventilation.

You may assume that every precaution is being followed. PPE worn. Safety zones respected. Checklists ticked. But how do you know?

More importantly: how do you know before an injury occurs?

AI Vision brings visibility to the unseen

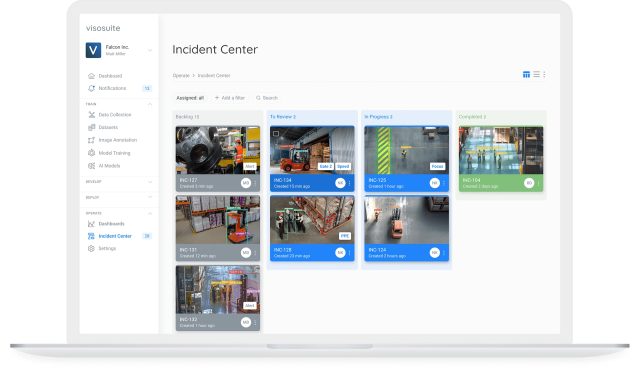

AI Vision provides the missing layer of visibility. It analyzes real-time video feeds from your existing CCTV infrastructure, automatically detecting and identifying potential hazards and deviations from safe procedures, without requiring anyone to record or report them.

These systems are trained to recognize:

- Improper PPE (e.g. missing jackets, hard hats)

- Unauthorized entry into restricted zones

- Forklift or vehicle proximity violations

- Unsafe postures or overexertion

- Failure to follow process sequences

The moment a deviation occurs, AI flags it, by timestamp, zone, and severity. No need to wait for a safety walk or an incident report.

Case study: food manufacturing site

At one multi-national food manufacturing site, leadership noticed a spike in minor injuries in a packaging area.

Traditional audits and investigations turned up nothing. After deploying AI Vision, the issue became clear: operators were consistently bypassing the designated walkway to shave a few seconds off their travel time – bringing them within inches of active pallet jacks.

This behavior wasn’t malicious. It wasn’t even hidden. It was routine. And until AI surfaced it, nobody realized how common it was.

Once identified, the team took simple corrective action: barrier placement, shift briefings with video clips, and a minor schedule adjustment. The shortcut stopped. The injuries stopped.

Closing the loop with data

One of the core strengths of AI Vision is how it turns behavior into actionable, auditable data. This means:

- Hotspot mapping: see where rule deviations occur most frequently

- Shift comparisons: compare compliance between day, swing, and night shifts

- Trend analysis: identify whether behaviors are improving or worsening over time

- Root-cause evidence: use video clips to train teams and improve SOPs

And because the system works 24/7, you get a continuous feedback loop, not just a snapshot during inspections.

Organizations that integrate AI Vision into daily safety routines report incident reductions of 25-40%, often within the first 6-9 months.

Empowering safety teams, not replacing them

AI Vision isn’t about catching people out. It’s about surfacing realities that help safety professionals make better decisions, faster.

For frontline supervisors, it means knowing where to focus their attention. Whereas for safety managers, it means justifying interventions with real data. And for corporate leaders, it means understanding whether documented policies are truly effective in practice.

Most importantly, it means giving workers tools to work smarter and safer, not harder.

Practical deployment, immediate impact

AI Vision platforms are designed for ease of use:

- No new hardware required: uses existing cameras

- Quick setup: operational in less than 72 hours

- Remote access: central teams can oversee multiple locations

- Custom alerts: tailor rules by zone, shift, or activity

That makes it ideal for dispersed teams, legacy environments, and facilities where continuous improvement is a safety and operational priority.

Changing the culture: show, don’t tell

Video has a unique power to drive behavior change.

With AI Vision, safety briefings become vivid. Toolbox talks feature real examples. Workers don’t just hear what went wrong: they see it.

Because AI alerts are consistent, transparent, and depersonalized, trust builds fast. It’s not you watching. It’s the system surfacing insights to keep everyone safe.

This creates a shared sense of accountability: a realistic safety program to shape the path of a truly pro-active safety culture.

Final thought: aligning plan with safety practices

No matter how well you write the rulebook, safety ultimately depends on behavior. And behavior depends on visibility, feedback, and trust.

With AI Vision, safety leaders finally have the tools to close the safety gap between work-as-imagined and work-as-done: not by policing people, but by empowering them.

Because the safest sites aren’t the ones with the most rules. They’re the ones where the right behaviors are consistently followed. Now, you can see the difference.