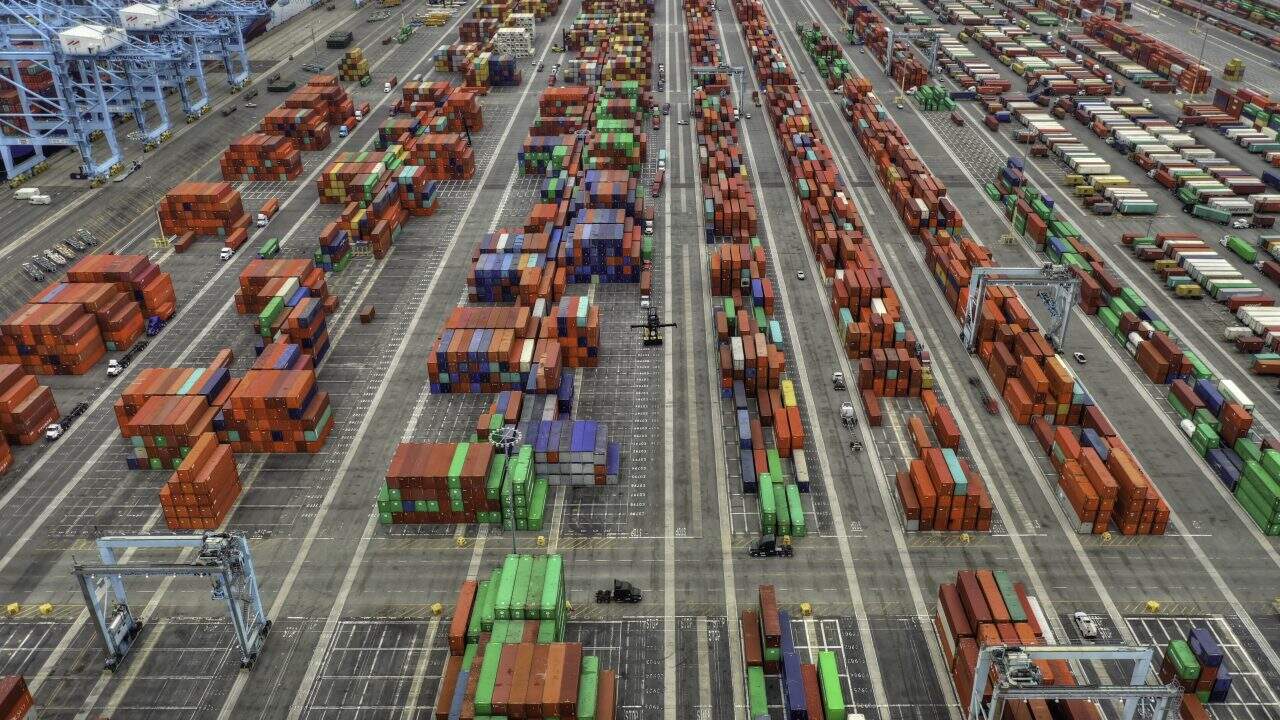

In today’s hyper-competitive logistics environment, operational leaders face an unrelenting challenge: deliver more with less.

- Less waste and downtime

- Shorter lead time

- Reduce waste

- Higher customer satisfaction

- Fewer safety incidents

- Continuous improvement

- No room for costly errors.

For supply chain directors and warehouse managers, the pressure to optimize is ever-present. We can do this by implementing lean intelligent solutions for supply chain effectiveness. Every square meter of floor space, every minute of labor, and every movement of material is under the microscope.

Across industries, the challenge remains the same. The pursuit of lean warehouse operations is no longer just about Kaizen events and 5S audits. The challenge is now about visibility.

Real-time, actionable, continuous visibility. And that’s where AI Vision is fundamentally rewriting the rules of supply chain management and warehouse optimization.

From blind spots to real-time insight

At the recent Total Supply Chain Summit, we spoke to logistics directors from Primark, Sigma, Vodafone, and Destiny Foods. We found that they all revealed a consistent pain point. They identified legacy CCTV systems that capture footage but deliver zero operational intelligence. Traditional video infrastructure sits idle, functioning as passive recorders rather than active contributors to operational efficiency.

The irony? Most warehouses already have the hardware foundation for digital transformation in logistics. They just don’t yet have the deployed intelligence layer to extract value from it.

AI Vision changes that dynamic entirely. By transforming existing camera feeds into real-time sources of structured data, computer vision for operations enables more efficient and dynamic automatic detection. This frees up time from manual observation to higher added-value tasks:

- Forklift bottlenecks at intersections

- Idle zones consume valuable space

- Blocked emergency exits

- Unsafe pedestrian-vehicle interactions, and

- Deviations from standard operating procedures

Without replacing cameras or overhauling infrastructure, AI solutions can support lean visibility. They do this by detecting, measuring, and continuously improving warehouse performance across every shift, every day. That could be inventory levels, optimized production processes, more efficient supply and management systems, and demand forecasting. Thus, streamlining operations and optimizing resources.

Key outcomes of AI Vision for optimizing supply chain and warehouse operations

We see three key outcomes from deploying AI Vision for leaner warehouse operations:

1. Operational efficiency

Real-time warehouse performance tracking reveals process delays, congestion points, unbalanced workflows, and equipment under-utilization. Video analytics at scale allows managers to gain insights that were previously invisible or required hours of manual review. As cycle times improve, the foundations for competitive advantage are laid.

2. Safety optimization

Automated near-miss detection reduces incidents before they escalate into injuries. Intelligent workplace safety monitors PPE compliance, emergency exit, and risk prevention with computer vision. These colutions operate 24/7 without fatigue or bias.

3. Cost reduction

Data-driven insights drive measurable gains in throughput, equipment utilization, and labor efficiency. Organizations implementing warehouse automation use cases report operational cost reduction of 15-30% within the first year, alongside improvements in HSE compliance monitoring. Computer vision can account for as much as one-fifth of that, so from 3%-6% savings.

Lean meets intelligent automation

The core principles of Lean – eliminate waste, standardize workflows, empower continuous improvement through visibility – align perfectly with the capabilities of AI-powered logistics. Each visual stream becomes a data point feeding continuous improvement loops that would make Taiichi Ohno proud.

Consider how process improvement with computer vision directly addresses the Eight Wastes of Lean.

1. Motion waste elimination

Video analytics identify inefficient movement patterns, revealing opportunities to streamline material flow and reduce travel time. Forklift monitoring solutions track vehicle paths to optimize traffic routes and minimize congestion.

2. Waiting time reduction

By analyzing queue patterns and bottlenecks, intelligent camera systems help balance workloads. This, in turn, eliminates idle time at receiving docks, packing stations, and loading bays.

3. Defect prevention

Automated quality inspection catches errors in real-time. In manufacturing, defect detection flags non-conforming items before they travel downstream, reducing rework and scrap.

4. SOP adherence monitoring

Visual analytics continuously verifies that staff follow standardized safety and quality procedures. From proper lifting techniques to hygiene protocols in food production, automated SOP compliance transforms compliance from periodic audits into continuous assurance.

5. Over-processing detection

AI Vision can identify redundant steps or unnecessary handling. This helps lean manufacturing analytics teams eliminate activities that don’t add value.

Intelligent supply chains are moving from spreadsheet-based operations to data-driven performance models. AI Vision bridges the gap between digital transformation ambition and day-to-day execution. It’s the operational layer that converts real-time data into actionable metrics, KPI dashboards, and continuous feedback loops.

Scalable efficiency across multi-warehouse operations

The most common question at the Summit was:

“Can we scale computer vision across multiple sites without replacing our existing camera infrastructure?”

The answer is a resounding yes, and increasingly, this is where the ROI case becomes solid.

Edge AI for logistics enables localized processing, bypassing the need for massive bandwidth or centralized cloud dependencies. With secure edge deployment, video processing happens on-premises, maintaining low latency while reducing infrastructure costs. This makes scalable CV infrastructure accessible to large, distributed operations with varied technology stacks. We’ve seen the optimization of aging paper mills with legacy systems to modern fulfillment centers with IP camera networks.

For organizations managing cross-site logistics across the UK, Ireland, or internationally, edge deployments ensure consistent performance. They eliminate connectivity constraints that previously limited multi-warehouse operations. Each site processes its own video feeds locally, while centralized dashboards aggregate insights for enterprise-wide visibility.

And critically, with privacy-safe video analytics and GDPR-compliant computer vision, organizations can implement real-time monitoring securely. Modern visual systems do not implement facial recognition. Instead, they use anonymous object tracking, zone-based monitoring, and behavioral analysis that respects worker privacy while delivering full operational insight.

Bridging Lean manufacturing and warehouse logistics

While much of the conversation around AI Vision focuses on warehousing, the technology delivers equally powerful results in lean manufacturing environments. Companies like Ross Pneumatics and Metsa Tissue are exploring visual intelligence for production line challenges. Innovating after discovering that manual oversight cannot effectively scale.

Lean manufacturing enablement through AI Vision includes:

- Conveyor belt monitoring: detecting jams, misalignments, or flow disruptions before they cause downtime

- Safety compliance: where industrial automation with AI prevents hand injuries, monitors restricted zones, and ensures workers wear proper PPE

- Production line optimization: to track cycle times, identify bottlenecks, and measure OEE (Overall Equipment Effectiveness) in real time

- Visual analytics: to provide supervisors with instant alerts of unmet quality standards or breached safety protocols

The integration between warehouse-to-factory operations becomes seamless when both environments share a common computer vision platform. Teams that track material flow, safety standards, and quality metrics create true end-to-end supply chain automation.

The business case for Lean AI Vision

Organizations across multiple verticals are already deploying AI Vision to drive tangible operational improvements:

1. Shrinkage and loss prevention

Sigma and other pharma warehouses are using theft detection in logistics to address low-value shrinkage without invasive surveillance. Warehouse security modernization provides zone-based monitoring and anomaly detection in video feeds while maintaining GDPR and computer vision compliance.

2. Forklift and pedestrian safety

Primark is exploring forklift monitoring solutions to reduce incidents in busy warehouses. Organizations reduce injury rates while protecting their workforce by tracking the following common metrics:

- Vehicle speeds

- Near-miss events

- High-traffic intersections

3. Cleaning and compliance verification

With an £8-9m annual cleaning budget, ODEON is interested in operational cleaning optimization. AI-enabled cleaning performance tracking verifies that standards across locations, reducing audit costs and improving consistency.

4. Quality control at scale

Ross Pneumatics seeks to scale automated quality inspection across eight production lines. Instead of manual photo-taking for defects, computer vision in factories provides continuous monitoring, instant alerts, and documented compliance with quality standards.

5. Event and crowd management

Merlin Entertainments (operators of theme parks and attractions) is exploring crowd and queue management analytics. This allows them to optimize guest flow, reduce wait times, and improve safety compliance for high-capacity venues.

These use cases prove that lean AI Vision is not a theoretical future: it’s a deployable competitive advantage today. By integrating AI Vision with existing systems, businesses achieve supply chain innovation and warehouse modernization without the prohibitive cost of infrastructure replacement.

Implementation without disruption

One of the most compelling aspects of modern AI retrofitting solutions is implementation without shutting down operations. They also work with existing cameras, so no replacements are necessary.

Warehouse AI solutions can be deployed progressively:

- Pilot zone deployment: start with a single high-value area (i.e., loading dock or production line) to demonstrate ROI

- Incremental expansion: scale to additional zones and sites based on proven results

- Integration with existing systems: connect AI Vision analytics to existing WMS, ERP, or CMMS platforms for unified operational dashboards

- Continuous improvement: use insights to refine processes, update SOPs, and drive cultural change toward data-driven operations

This phased approach minimizes risk, proves value quickly, and allows organizations to learn and adapt before full digitization.

Conclusion: Lean is already a vision system

Lean manufacturing and lean warehouse operations were always about seeing waste, visualizing flow, and making problems visible. The Andon cord, kanban boards, and gemba walks are all tools designed to make inefficiency impossible to ignore.

AI Vision products and services support the evolution of that same philosophy. It turns cameras into sensors for continuous improvement and every video frame into a data point for performance optimization. In the end, every facility becomes a source of real-time operational intelligence.

For supply chain leaders ready to transform how they achieve operational excellence, AI Vision isn’t just another technology initiative. It’s the enabling infrastructure for the next generation of lean operations, automatically, continuously, and at scale.

The future of Lean operations isn’t about working harder to see waste on stream maps. It’s about building systems that see waste for you. And the organizations adopting AI Vision today are the ones defining competitive advantage tomorrow.