Hazardous zone intrusion is a systemic risk existing in nearly every industrial operation. Whether around heavy machinery, automated lines, vehicle traffic, high-voltage assets, or restricted areas, the risk is constant and unavoidable. What separates high-performing organizations from the rest is not the absence of hazards, but rather how effectively those hazards are controlled in real-time.

For enterprise leaders, hazardous zone intrusion is more than a safety issue. It directly affects operational continuity, regulatory exposure, insurance costs, and workforce trust. Incidents rarely occur because safety rules are missing. They occur because enforcement breaks down across sites, shifts, or moments of inattention.

Why Traditional Controls No Longer Scale

Manual supervision, access rules, and periodic audits were never designed for today’s operating complexity. As environments grow larger and more automated, these approaches struggle to deliver consistent enforcement. Visibility gaps emerge. Response times lag. Near misses go undocumented until they become incidents.

The result is a reactive safety posture that identifies problems after they occur, rather than preventing them.

AI Vision as the standard for hazardous zone identification

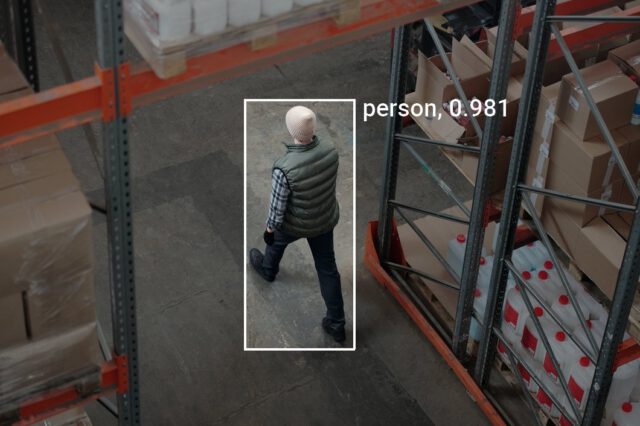

Computer Vision, or AI Vision, has become the most effective way to enforce hazardous zone boundaries at scale. By continuously monitoring defined zones in real time, intelligent visual systems detect when people, vehicles, or equipment enter restricted areas and trigger immediate alerts or interventions.

This approach provides consistent, always-on enforcement that does not depend on human availability or attention. It works across sites, adapts to changing conditions, and creates a reliable safety layer embedded directly into operations.

Just as importantly, it generates objective data. Leaders gain visibility into where intrusions occur, how often, under what conditions, and whether corrective actions are working.

What enterprise leaders gain

For executives and directors responsible for safety, operations, and risk, hazardous zone detection delivers clear, measurable value:

- Fewer safety incidents and near misses through real-time intrusion detection

- Reduced liability and insurance exposure driven by stronger, provable safety performance

- Lower unplanned downtime caused by preventable accidents and shutdowns

- Consistent enforcement of safety standards across locations, teams, and shifts

These outcomes compound over time, improving both operational resilience and organizational credibility.

From Compliance to Operational Control

The most meaningful shift enabled by AI Vision is moving safety from compliance documentation to system-level control. Hazardous zone rules are no longer passive policies or signs on a wall. They become actively enforced constraints within the operating environment.

For decision-makers, this means fewer surprises, clearer accountability, and greater confidence that safety measures are working as intended, not just on paper, but in practice.

As industrial environments continue to scale and automate, hazardous zone intrusion detection is no longer a nice-to-have. It is a foundational capability for organizations serious about protecting people, maintaining uptime, and operating with discipline at enterprise scale.