This article covers the most important topics in the field of machine vision. In particular, I will cover

- What is machine vision? An easy-to-understand definition

- Difference between machine vision and computer vision

- What are intelligent systems?

- How does machine vision work? Components and process

- Machine vision cameras

About us: Viso.ai provides the leading end-to-end Infrastructure for Computer Vision Applications. The Viso Suite platform enables industry leaders to build, deploy, and scale high-performance computer vision applications. Get a demo for your company.

What is Machine Vision Technology?

Machine vision is the ability of a computer to see the environment. For example, a video camera runs with analog-to-digital conversion and digital screen processing. The image data is then sent to a computer or robot controller.

Human eyes can sense the range of electromagnetic (EM) wavelengths from 390 to 770 nm. However, video cameras are responsive to wavelengths much broader than this, with some machine vision systems operating at X-ray, infrared, or ultraviolet (UV) wavelengths. Machine vision supports a computer’s ability to see.

A machine vision system uses a sensor in the robot to see and identify a physical entity using a computer. Various industrial processes, including recognition of optical characters, material inspection, currency recognition, object recognition, pattern recognition, and electronic component analysis, use this system.

One of the easiest ways to understand a computer vision system is to consider it the eyes of a machine. This system improves quality, efficiency, and operations.

Machine Vision vs. Computer Vision

Computer vision and machine vision are overlapping technologies. An intelligent system needs a computer and a particular software tool to function, while computer vision doesn’t need to be linked to a machine.

For example, computer vision can process images or videos online, along with images from motion detectors, infrared sensors, or other sources. The next megatrend is Edge AI, moving computer vision from the cloud to the edge, close to the sensor gathering data. Machine vision is a sub-class of computer vision.

What are Intelligent Systems in Machine Vision?

Machine vision systems are embedded components that use data extorted from online images to automatically guide manufacturing and production operations, such as go/no testing and quality control processes. These systems can also play a role in inspection operations and automated assembly verification. They can do so using their capabilities to direct material handling equipment to position products or materials required in a particular process.

These systems have a wide range of applications in different industries that can automate time-consuming, repetitive jobs that would otherwise be tiring to a human operator. The use of such systems allows for the examination of products or components in a process. It results in higher yields, increased quality, low defect rates, reduced costs, and higher consistency of process results.

How does Machine Vision Work?

The Components of a Machine Vision System

Machine vision systems, also called vision inspection systems or automated vision systems, include many parts commonly found in most systems. Even though each of these parts has its function, they have a particular role in an intelligent system when working together.

These system parts typically include the following five elements:

- The Lightning System

- Sensors

- Lens or Optical System

- Vision Processing System

- Communications System

Machine vision systems include distinct elements or may be combined into a single unit, such as a smart camera that combines the functions of the discrete components into a single package. Irrespective of whether it is using a distinct or integrated system, the efficiency of the intelligent system also depends on the nature of the parts getting analyzed. The more effective the orientation or placement of the component is, the better the system’s performance.

The Process and Steps of Implementing Machine Vision Products

Let’s see how these discrete elements work together when evaluating a product in a manufacturing operation — which is a typical example of an automated system in practice.

- The process begins when a sensor identifies the presence of a physical entity.

- The sensor then stimulates a light source to light up the area and a camera to capture the picture or a component of the entity.

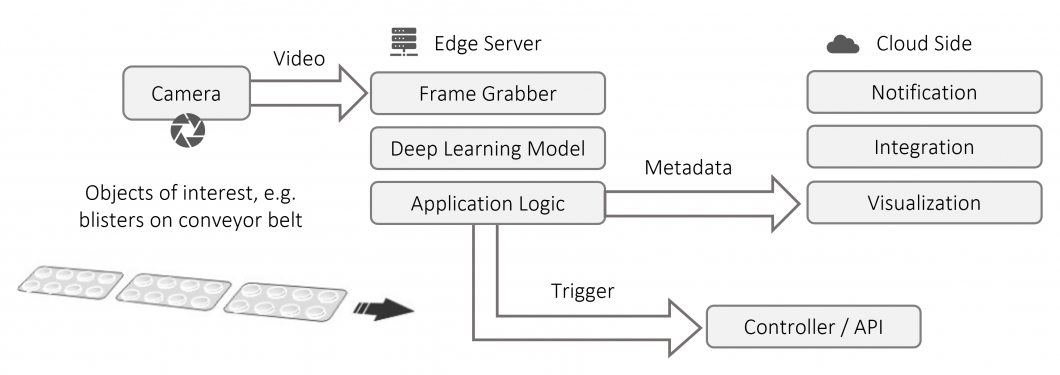

- Next, the frame-grabber, a digitizing device, converts the image captured by the camera into digital output.

- The digital output is then saved on a computer so the system software can examine it.

- The software tool compares the file against a series of predetermined criteria to determine anomalies. If any such anomaly is detected, the product will fail inspection.

Understanding the anatomy and capabilities of systems can help guarantee that an application is suitable for camera-based systems. In reality, a camera can capture whatever a human eye can see, and deciphering and reporting the data can be a little daunting. However, with the help of a vendor knowledgeable in the systems, lighting, and techniques, we can save a significant amount of time in the long run.

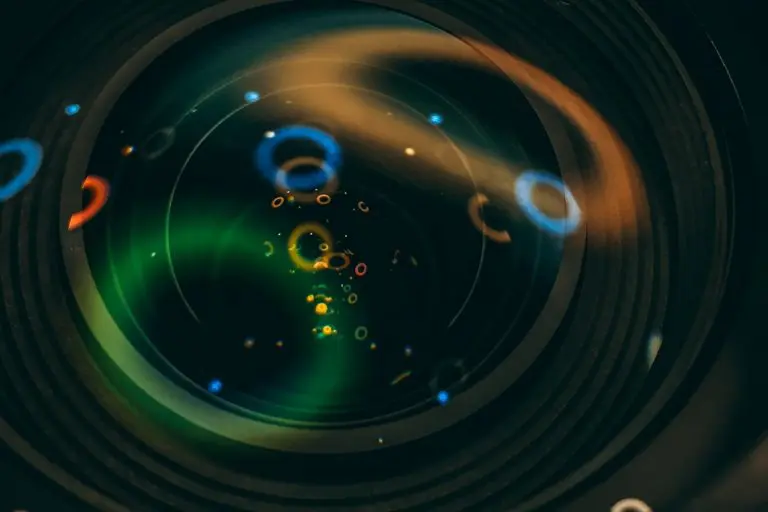

Machine Vision Cameras

Machine vision cameras are based on sensors with special optics to capture images, process, evaluate, and measure different characteristics through hardware and computer software for precise decision-making. If engineered with the correct optics and resolution, a machine vision camera can detect small object details almost invisible to the human eye.

The major components of an intelligent camera system are lighting, sensors, communications systems, lenses, and vision processing systems. The camera sensor converts the light into an online digital image. It is then sent to the processor for analysis.

When selecting the right machine vision camera, you have to consider several factors. Initially, it is essential to ensure the camera you’ve chosen is suitable for the application you are looking for. For instance, a camera used for robot guidance won’t have the same characteristics as the one used for production control. The choice of any feature will depend on both your budget and your application.

Machine vision cameras are used in various industries, including pharmaceuticals, industrial manufacturing, semiconductors, food and beverages, electronics, automotive, and packaging and printing. Moreover, it has a lot of applications in pattern recognition, location analysis, and inspection with cameras.

The purpose of the system in location applications is to find the physical entity and detect its position and orientation. In an inspection application, a system validates certain features, including the presence or absence of the correct label on a bottle or chocolates in a box. In identification applications, the purpose of a vision system is to read different codes and alphanumeric characteristics.

Applications of Machine Vision

Quality Control in Manufacturing

Machine vision systems are designed to find defects in manufactured products, assess their dimensional precision, and ensure component integrity. These systems depend on advanced image processing algorithms and HD cameras to analyze products in real-time, ensuring that they stick to stringent quality standards. Such applications reduce production costs, minimize waste, and improve product quality.

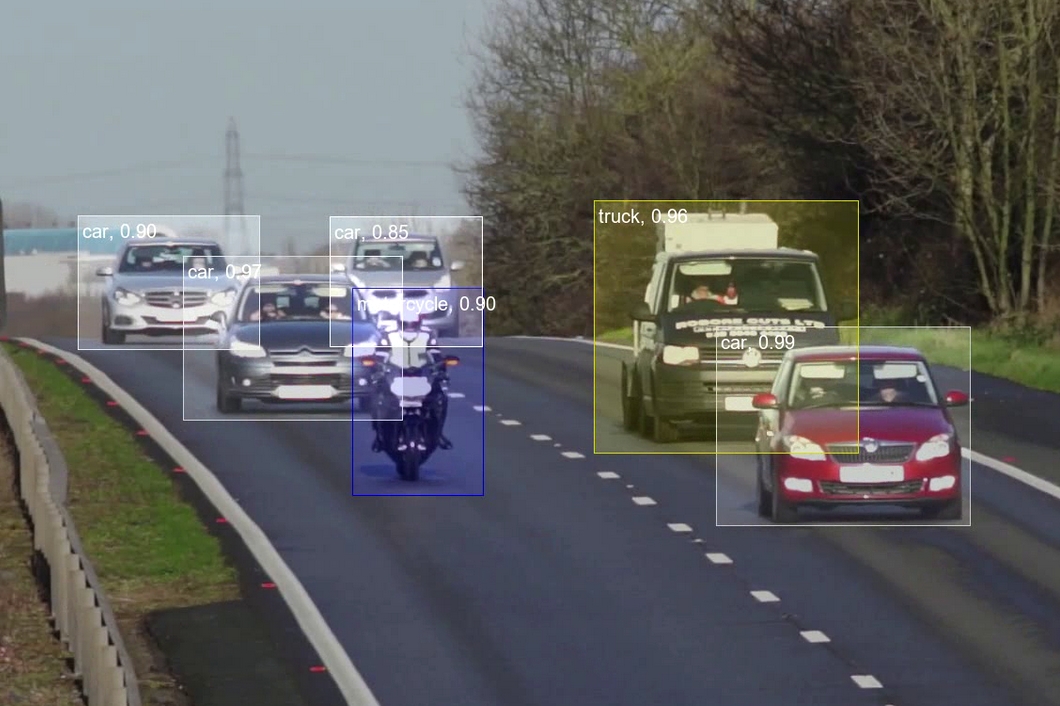

Autonomous Vehicles

Machine vision plays an important role in transforming autonomous vehicles. A multitude of sensors, including cameras, are used by vehicles to perceive their surroundings, interpret road signs, recognize pedestrians, and navigate safely. The Machine Vision algorithms process the data from the sensors thereby enabling autonomous vehicles to make quick decisions, avoid collisions, and enhance transportation systems. With advancements, these vehicles can also reduce accidents and congestion, reshaping the future of mobility.

Agriculture

The machine vision algorithms can analyze vast agricultural fields to identify areas that are affected by pests or diseases in real time with the help of aerial drones. This would help the farmers target interventions precisely where needed, reducing the application of blanket pesticides and minimizing the environmental impact.

Healthcare

Machine Vision can enhance the diagnostic abilities of radiologists. It can precisely detect diseases and anomalies within medical images. It can also quickly and accurately analyze vast datasets, such as MRI or CT scans helping medical professionals to make critical decisions about patient treatment plans and care. This has opened up new avenues for early disease detection and customized medicines.

What’s Next for Machine Vision?

Edge Intelligence, or Edge AI, is the next big trend, moving machine learning for image recognition from the cloud to physical edge devices connected to the cameras. This is relevant for the future of machine vision applications since advances in edge computing (on-device processing) make it possible to apply deep learning capabilities in traditional computer vision tasks. For example, deep learning machine vision is useful for camera inspection systems and vision systems for quality control.

Further Reads for Machine Vision

If you want to learn more about how Deep Learning brought great advances in the field of Computer Vision, I recommend you to check out the following articles.